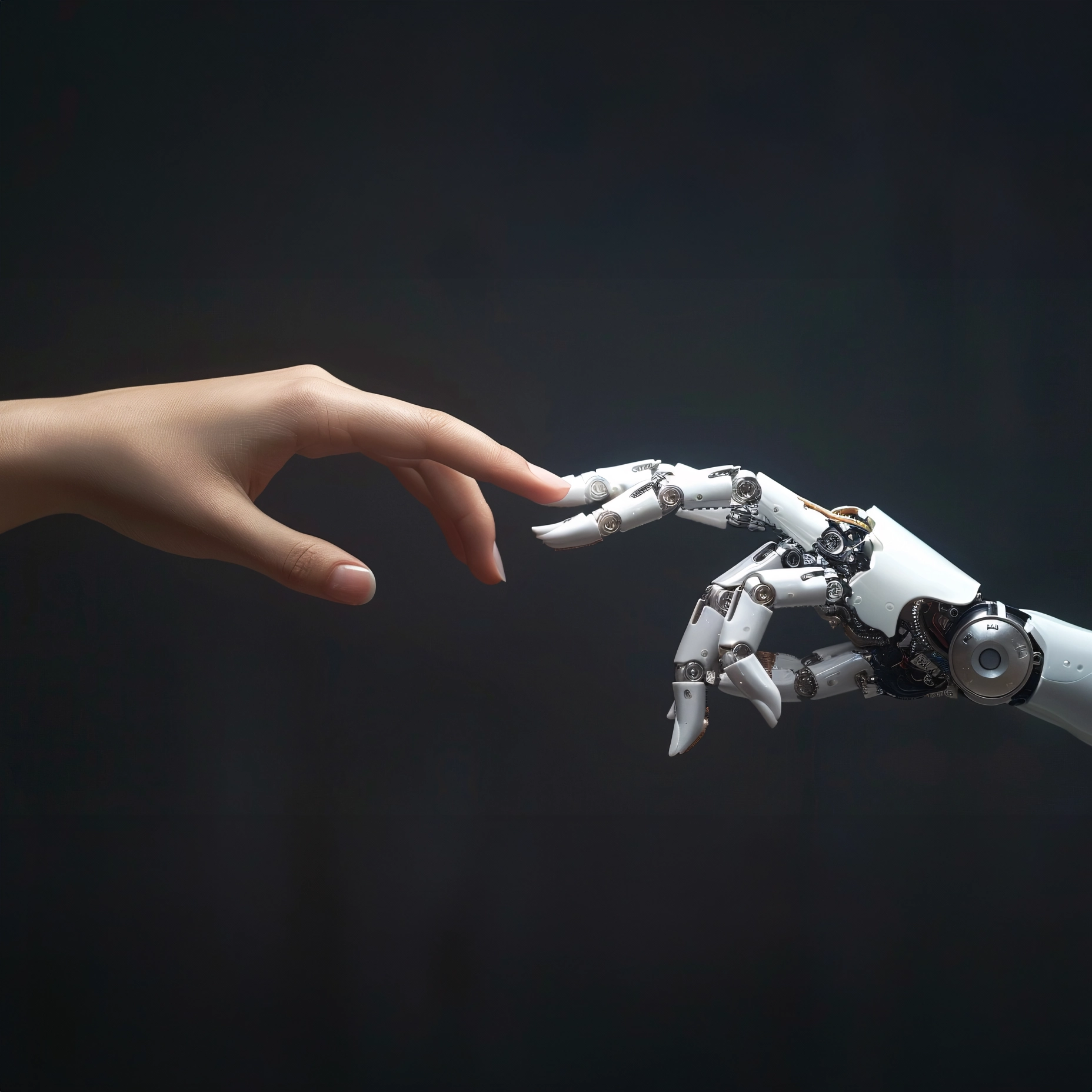

Empowering Digital Intelligence, Engineering the Future

For over 40 years, we have been shaping the future of engineering. We have witnessed the evolution of simulation, driven it forward, and now amplify it through the power of AI and HPC. Our expertise originates in research laboratories and grows through real-world business challenges, where we transform complex ideas into tangible innovation.

We are the partner that walks alongside you, building digital ecosystems that enhance creativity, design, and manufacturing. Because when experience and cutting-edge technologies come together, innovation is no longer just a goal: it becomes a real, lasting, and transformative impact.

Keep Reading