smart prodactive

What does it take to boost your shopfloor? Data, traceability, process optimization. In other words, smart prodactive!

smart prodactive is a product of EnginSoft SpA.

smart prodactive is a product of EnginSoft SpA.

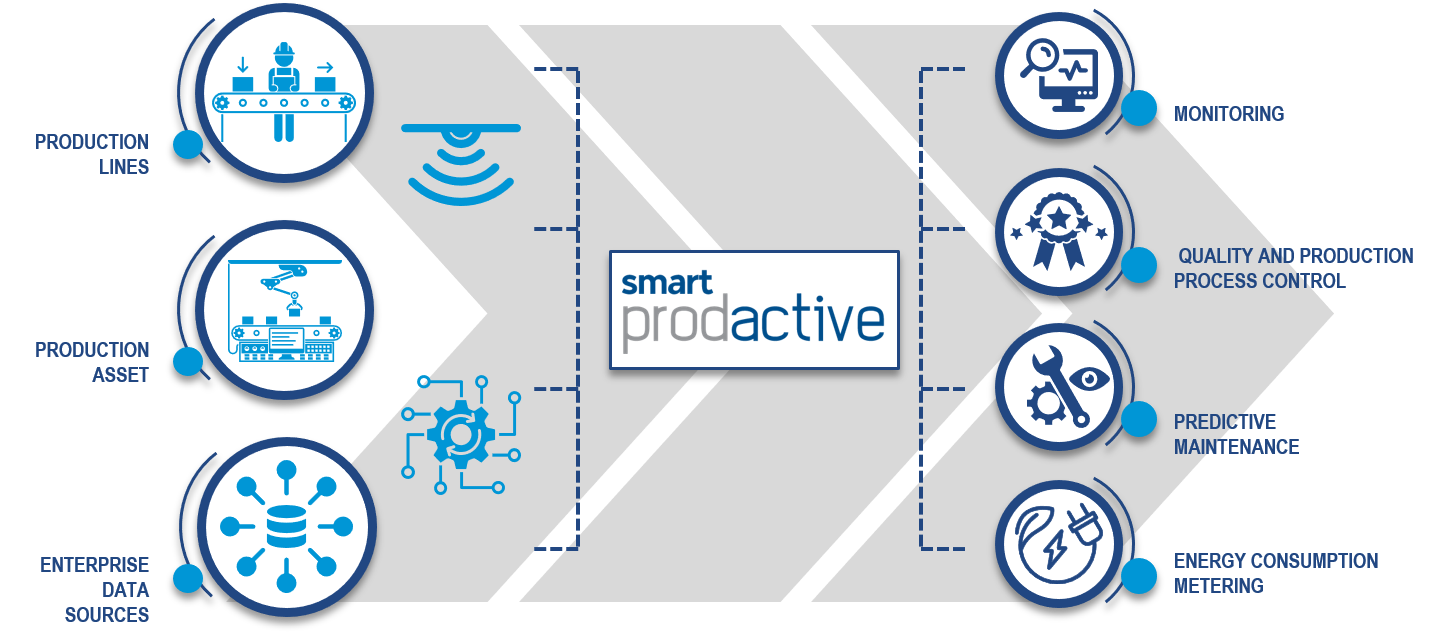

smart prodactive is the web-based platform that brings companies into the era of data and artificial intelligence in the following steps:

The platform is based on a microservices architecture, easily scalable and avilable both on-premise and on cloud as SaaS. The main modules are:

The smart prodactive platform is sold on an all-inclusive basis, with comprehensive support tailored to the needs of the business. We provide our customers with platform start-up support, shop floor digitalisation consultancy, production process optimisation and sustainability and ESG modelling support.

technical paper

This work was developed within the “MUSIC” Project (MUlti-layers control & cognitive System to drive metal and plastic production line for Injected Components), supported by European Union [FP7-2012-NMPICT-FoF] under grant agreement number n°314145. The authors would like to thank the MUSIC consortium (www.music.eucoord.com).

smart prodactive

technical paper

This work was developed inside “MUSIC” Project (MUlti-layers control & cognitive System to drive metal and plastic production line for Injected Components), supported by European Union - [FP7-2012-NMP-ICT-FoF] under grant agreement number n°3141. The authors would like to thank the MUSIC consortium (www.music.eucoord.com), and particularly RDS Moulding Technology SpA.

smart prodactive

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

The text provides an in-depth account of Stefano Odorizzi’s journey in founding and growing EnginSoft, our engineering company specializing in computer simulation and modelling. Established in 1984, EnginSoft overcame early challenges, such as the high cost of computing, to emerge as a leader in simulation services, particularly in the fields of mechanical engineering and computational fluid dynamics (CFD). The narrative highlights several key milestones in the company’s history.

cfd metal-process-simulation industry4 news mechanics optimization

CASE STUDY

This technical article illustrates the advantages of using virtual simulation to evaluate the thermal processes of die casting to reduce the formation of residual stresses and deformations in the components produced.

metal-process-simulation mechanics magma

CASE STUDY

Material models used in structural finite element analysis (FEA) are often one of the key aspects that engineers need to describe very accurately.

optimization modefrontier ls-dyna