Manufacturing, Photonics

The main objective of SHINE PV is to develop alternative technological routes to mainstream advanced photovoltaic (PV) production at lower costs and create opportunities for the differentiation of EU manufacturers (cells, modules, equipment and materials) to enhance their competitiveness on the global PV market.

The expectation of the project is to integrate SHINE PV process steps and enable an increase of solar cell efficiency of 0.5% absolute versus the reference process (as combination of efficiency increase from metallization, post processing and interconnection) with a simultaneous CoO reduction of 4% to 10%, depending on the different technologies adopted, due to reduced material costs and increased equipment productivity.

SHINE PV will develop alternative technological routes for two solar cell designs: Heterojunction (SHJ) and Tunnel Oxide Passivared Contact (TOPCon) solar cells, covering the three key steps in the back-end manufacturing: metallization, post-processing and interconnection. SHINE PV will identify synergies and differences between the two cell technologies, demonstrate different flows and down-select the most promising ones in terms of cost of ownership and high-volume manufacturing readiness.

The expectation of the project is to integrate SHINE PV process steps for metallization, post-processing and interconnection and enable an increase of SHJ/TOPCon solar cell efficiency of 0.5% absolute (module power increase of 2%) versus the reference process (screen printed metallization and MBB) with a total Cost of Ownership (CoO) reduction ranging from 4% to 10%, depending on technology choice, equipment productivity and materials costs.

SHINE PV project will demonstrate the integrated innovative processes and novel equipment both virtually and within physical pilots at industrial partners at TRL7.

SHINE PV aims to:

EnginSoft leads WP5: Process Integration, demonstration and evaluation, which scope is to create simulation models of the integrated SHJ and TOPCon process to provide realistic representations of the manufacturing process flows and to virtually optimise and validate their performance.

Manufacturing digital models will be developed and applied to demonstrate the manufacturing equipment and integrated production chains, including all the available processes and equipment alternatives and further exploring their scope.

APPLIED MATERIALS IRELAND – APPLIED MATERIAL ITALIA – COMMISSARIAT A L ENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES – FRAUNHOFER GESELLESCHAFT ZUR FORDERUNG DER ANGEWANDTEN FORSCHU – HIGHLINE TECHNOLOGY GMBH – INTERUNIVERSITAIR MICRO-ELECTRONICA CEMTRUM, ARKEMA FRANCE SA, POLYMER COMPETENCE CENTER LOBEN GMBH, IPTE AUTOMATION OU, SOLTECH, HOLOSOLIS SAS, UNIVERZA V LJUBLJANI, PI PHOTOVOLTAIK-INSTITUT BERLIN AG, NEDERLANDSE ORGANISATIE VOOR TOEGEPAST NATUURWETENSCHAPPELIJK O, AMIRES THE BUSINESS INNOVATION MANAGEMENT INSTITUTE ZU, BEDIMENSIONAL SPA

Funding Scheme Horizon Europe | Call identifier HORIZON-CL5-2024-D3-01-01, Grant Agreement No 101172902

Some of our competences in research and technology transfer

Research project

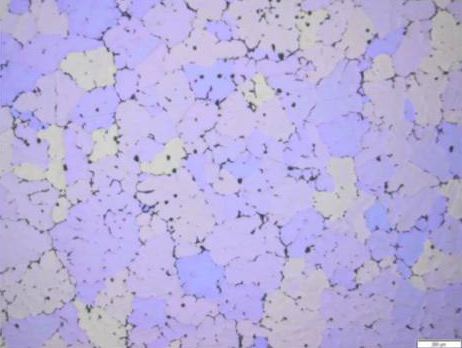

L’innovatività del progetto GAP consiste nello sviluppo di materiali metallici innovativi, con potenzialità applicative multi-settoriali, incrementate dalla sperimentazione di nuove tecnologie specifiche (utilizzo di anime ceramiche per la pressocolata, trattamenti superficiali, metodologie di giunzione).

Research project

The main aim of the project is to set out the knowledge and skills that a competent simulation engineer (CAE engineer) should possess, and to develop a set of tools that will enable engineers to develop, manage and certify their competencies within a wide range of industry sectors.