EZtol

The 1D tolerance stack up analysis tool

EZtol is a product of Sigmetrix LLC.

EZtol is a product of Sigmetrix LLC.

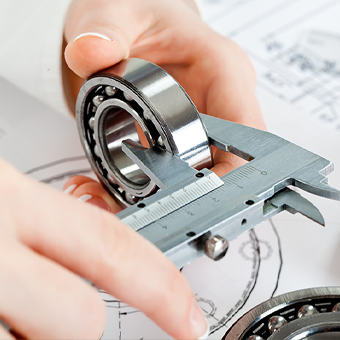

EZtol is a 1-Dimensional tolerance stackup analysis program designed to assist in understanding the impact of the accumulation of part-level dimensional variation and part-to-part assembly variation sources and the impact that they have on assembly-level requirements.

Today such analyses are performed in a spreadsheet, most commonly Microsoft® Excel®. Much work is required in creating spreadsheets that manage all of the product requirements simultaneously with consideration of common dimensions and tolerances that feed each one, properly including the impacts of the more complex geometric tolerances, and properly calculating the statistical results. Analysis spreadsheets often include a visual diagram either from the model or an assembly-level drawing to help explain the components of each of the analyses, but these too must be maintained as updates are made.

brochure

Per analisi delle tolleranze si intende una metodologia

che si utilizza nella progettazione di un prodotto, per comprendere

come le imperfezioni di parti,

in fase di fabbricazione, e di prodotti, in fase di assemblaggio, influenzino la

capacità di un prodotto finito di soddisfare le aspettative e le richieste del cliente.

Scopri come EZtol sia lo strumento indispensabile per comprendere l’impatto dell’accumulo di

variazioni dimensionali e geometriche sui requisiti delle parti e dell’assieme in modo semplice, efficiente e veloce.

EZTOL

Find out how and why to implement the "Dimensional Management" method.

Visit the dedicated section

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

This article is the first part of a four-part mini-series exploring key aspects of modern tolerance management in product development. It focuses on Dimensional Management (DM) — a simulation-based engineering methodology essential for ensuring dimensional quality across a product’s lifecycle.

tolerances mbdvidia comparevidia gdtadvisor cetol

CASE STUDY

This article examines the simulation of an RCD to determine the factors that affect its response times.

appliances ansys cetol recurdyn tolerances

CASE STUDY

This article examines the simulation of an RCD to determine the factors that affect its response times.

appliances ansys cetol recurdyn tolerances

CASE STUDY

This article describes how EnginSoft supported Metasystem in acquiring the know-how to satisfy future customer requests on the one hand, and to create projects that are as profitable as possible in terms of waste minimization, on the other hand.

automotive tolerances cetol

CASE STUDY

This article explores the practical implementation of Geometric Dimensioning and Tolerancing (GD&T) according to the ISO GPS standards, focusing on the functional definition and consistent application of Datum Reference Frames (DRFs). DRFs, derived from a component’s functional geometry and assembly sequence, constrain six degrees of freedom to ensure stable alignment and reproducibility during production and assembly.

tolerances mbdvidia comparevidia gdtadvisor cetol