Multiscale.Sim | Multiscale analysis system

A new tool for Ansys that facilitates materials testing and microscopic analysis of composite materials

Multiscale.Sim is a product of Cybernet Systems Co.

Multiscale.Sim is a product of Cybernet Systems Co.

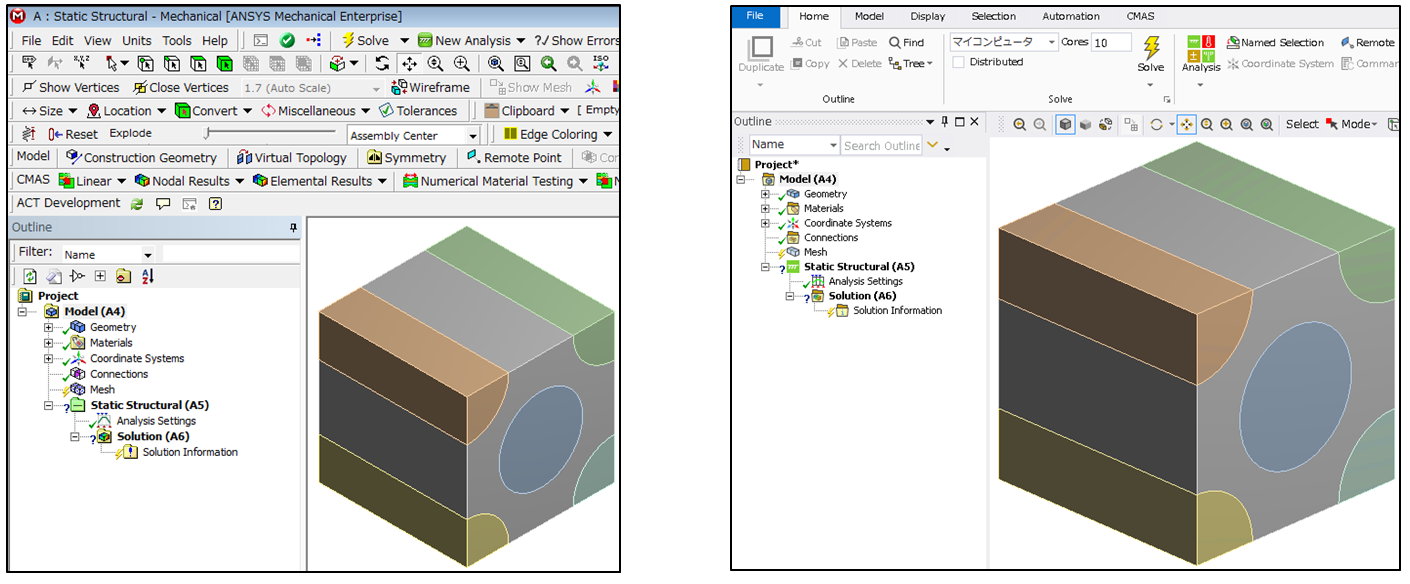

The multiscale analysis technique is designed to overcome complex materials problems. Using this technique, all material constants can be evaluated without expensive experimental campaigns. Cybernet Systems Co. has developed a multiscale analysis CAE tool called the “Multiscale.Sim”. Multiscale.Sim has been embedded in the Ansys Workbench GUI using the Ansys Customization Toolkit (ACT) techniques, making it very easy to use and allowing it to offer leading high-performance productivity for Ansys Workbench users. The Multiscale.Sim tool can help engineers to resolve challenges around materials modeling and characterization.

Using the two functions of homogenization and localization analyses makes it possible to perform a multiscale analysis of the inhomogeneous material microstructure of a composite material, such as fiber-reinforced plastic or metal, honeycomb, filler dispersion, lattice structures, and so on.

Material property values are calculated by numerical material test of micro structure without material tests that were required conventionally. The results enable prediction of the macroscopic behaviour by the macro structural analysis. Further, it is possible to predict the microscopic behaviour by going back to the micro structure analysis again.

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

This technical article presents a study to design a device that operates entirely on the principle of trapped vortices that intrinsically improve the mixing of hot combustion gases with fresh mixture, a characteristic that is essential both to diluted combustion and to Moderate or Intense Low-oxygen Dilution (MILD) combustion.

ansys cfd turbomachinery energy oil-gas

CASE STUDY

This technical article discusses some of the problems of using finite element method (FEM) simulation software for composite material analysis and introduces new solutions from CYBERNET with Ansys Software for solving these problems.

composites ansys multiscale

CASE STUDY

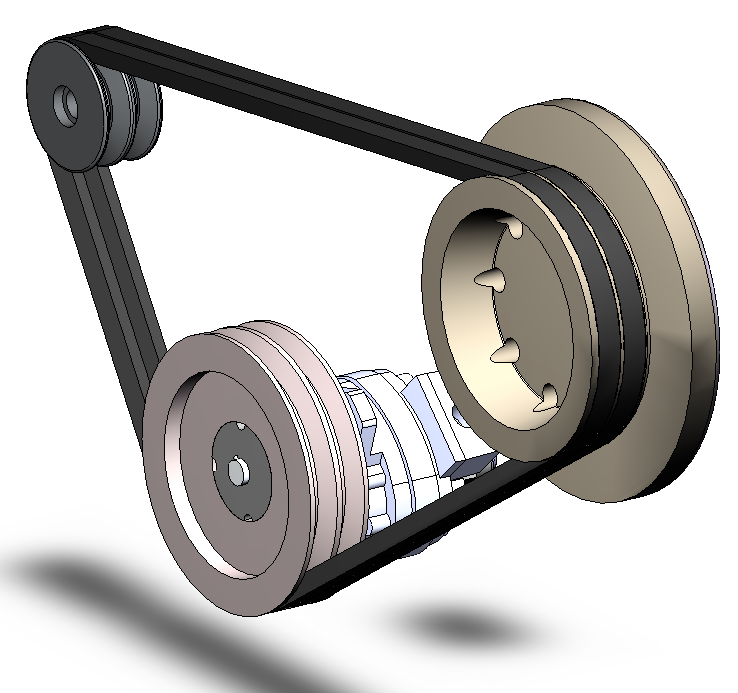

A virtual prototype of a belt must necessarily include the high flexibility of the belt itself, as well as a detailed description of the contacts. This is another scenario where RecurDyn provides better functionality than its competitors.

multibody mbd-ansys recurdyn

CASE STUDY

Dimensional management in modern manufacturing demands more than just accurate geometric tolerances—it requires data consistency, traceability, and automation across the entire product lifecycle. Traditional practices like annotated PDFs and Excel-based inspection plans introduce risk and inefficiency by detaching product and manufacturing information (PMI) from the 3D model. Siemens’ NX Inspector addresses this challenge through the introduction of Model-Based Characteristics (MBC)—standards-compliant, machine-readable data objects that convert each PMI requirement into a uniquely identified, traceable element within the CAD environment.

mbdvidia tolerances

CASE STUDY

This detailed technical case study describes how the students arrived at a supersonic aircraft drone prototype using MATLAB and modeFRONTIER in order to reduce the time and costs of numerical and wind-tunnel testing.

automotive modefrontier optimization