Aeronautics

The SERENA project aims to develop a prototype propulsion system for a General Aviation- category aircraft based on hybrid power technologies (hydrogen-fueled cells, batteries, and super-capacitors).

SERENA contributes to the subject of fuel cells for Advanced Air Mobility (AAM) applications to allow air transportation with zero emissions by small and medium-sized air taxis and unmanned aircraft. SERENA will also investigate emerging storage and energy-recovery technologies for energy reuse during flight and take-off, landing, and taxiing. The propulsion system will have a 90% lower climate impact than conventional systems.

SERENA will expand the experimental practices for new-generation aircraft at the Grottaglie Airport Test Bed, a strategic infrastructure in Southern Italy. The main innovations and benefits include: the generation of specific knowledge in the strategic high-tech sector of the hydrogen supply chain; an increase in investment; and the creation of highly qualified professionals.

ES is contributing numerical simulation to certify the energy storage and distribution system; is developing and verifying a digital twin of the propulsion system; and is developing a decision support system (DSS).

Distretto tecnologico aerospaziale | Enginsoft Spa | Novotech Srl | Università del Salento – Department of Innovation Engineering

Funded by the European Union - NextGenerationEU - Italian National Recovery and Resilience Plan (NRRP) - M2C2.3.5

by Marco Corti | EnginSoft

Leonardo Lecce | Novotech

Futurities - Spring 2025

The aviation industry's pursuit of sustainability is accelerating the exploration of hydrogen fuel cells as a zero-emission propulsion solution. The SERENA project—driven by DTA, EnginSoft, Novotech, and UniSalento—focuses on integrating hydrogen fuel cells and batteries into general aviation, specifically for the Seagull light aircraft. A key challenge lies in safely managing hydrogen’s high flammability. To address this, the project used CFD simulations to assess the effects of a potential gas leak inside the aircraft cabin. Initial tests with natural ventilation revealed significant combustion risks within seconds. However, by implementing forced ventilation, optimizing airflow geometry, and using fast-response sensors, the team reduced hydrogen concentration to safe levels (<1%) even under continuous leak scenarios. These findings are a critical step toward enabling safe hydrogen-powered flight.

Read the article

Some of our competences in research and technology transfer

Research project

Development of a novel “manufacturing system-level quality and productivity optimizer tool” enabling the evaluation of the system level impacts of the defect avoidance policies that can be adopted within single processes.

Research project

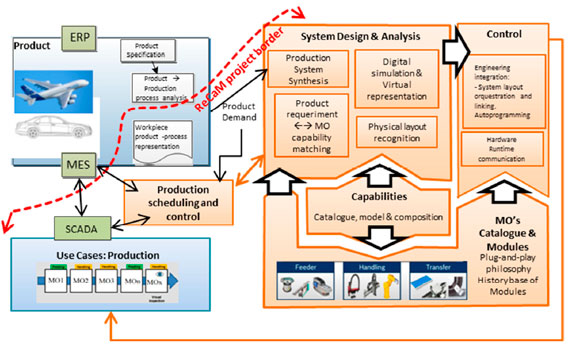

The ReCaM-project demonstrates at TRL 7 a set of integrated tools for the rapid and autonomous reconfiguration of agile production systems