FactoryTalk DataMosaix

Got Data?

Put it to work with FactoryTalk DataMosaix

FactoryTalk DataMosaix is a product of Rockwell Automation

FactoryTalk DataMosaix is a product of Rockwell Automation

FactoryTalk DataMosaix is an advanced Industrial DataOps platform developed by Rockwell Automation, designed to streamline access to complex industrial data by integrating Information Technology (IT), Operations Technology (OT), and Engineering Technology (ET). This solution makes data more accessible, meaningful, and actionable, enabling manufacturing organizations to unlock greater value from the vast amounts of data generated across their production systems—enhancing efficiency and effectiveness in decision-making.

Simplifies access to complex industrial data, breaks down data silos, and accelerates decision-making by providing unified, real-time insights.

Contextualized data and intuitive tools empower domain experts and analysts to derive valuable insights and make informed decisions from industrial data.

Pre-built industry-focused applications and connectors speed up the deployment of Industrial DataOps solutions, reducing implementation time and costs.

Designed to scale with large and complex industrial operations, FactoryTalk DataMosaix can handle massive data volumes while providing a unified, comprehensive view of your operations.

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

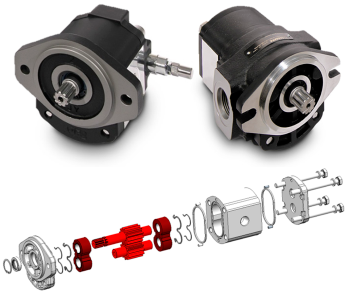

In this technical case study, EnginSoft assists Casappa to further refine an already-optimized standard series pump for an electrical motor and generator

mechanics optimization modefrontier

CASE STUDY

The text discusses the importance of digital simulation models in modern factory design and reconfiguration, particularly in response to shorter product lifecycles and increased customization demands. Traditional design methods often lead to inefficiencies and high costs, making digital simulation essential for creating flexible and adaptable production systems. The article highlights a case study involving a furniture assembly factory, where a manufacturer needed to efficiently handle a variety of custom kitchen cabinet orders. The system integrator was tasked with designing a robotic assembly line that could maintain production efficiency despite the high variety of products.

industry4 SIMUL8

CASE STUDY

This article discusses a multi-objective optimization study to determine the optimal matrix for the routing of the actuating cable system in order to minimize the cable load on the robot and maximize the robot’s payload.

optimization modefrontier mechanics electronics

CASE STUDY

Further reduction of the heat loss compared to the best design of the NSGA-II first phase design optimization: a further 4% gained

cfd biomechanics ansys modefrontier optimization

CASE STUDY

Modern propeller requirements involve many different characteristics, not limiting only to maximum efficiency, but considering also propeller cavitating behavior and, more and more, its side effects, in terms of radiated noise and pressure pulses.

marine modefrontier optimization