CompareVidia

Derivative CAD Validation & Revision Comparison

CompareVidia is a product of Capvidia.

CompareVidia is a product of Capvidia.

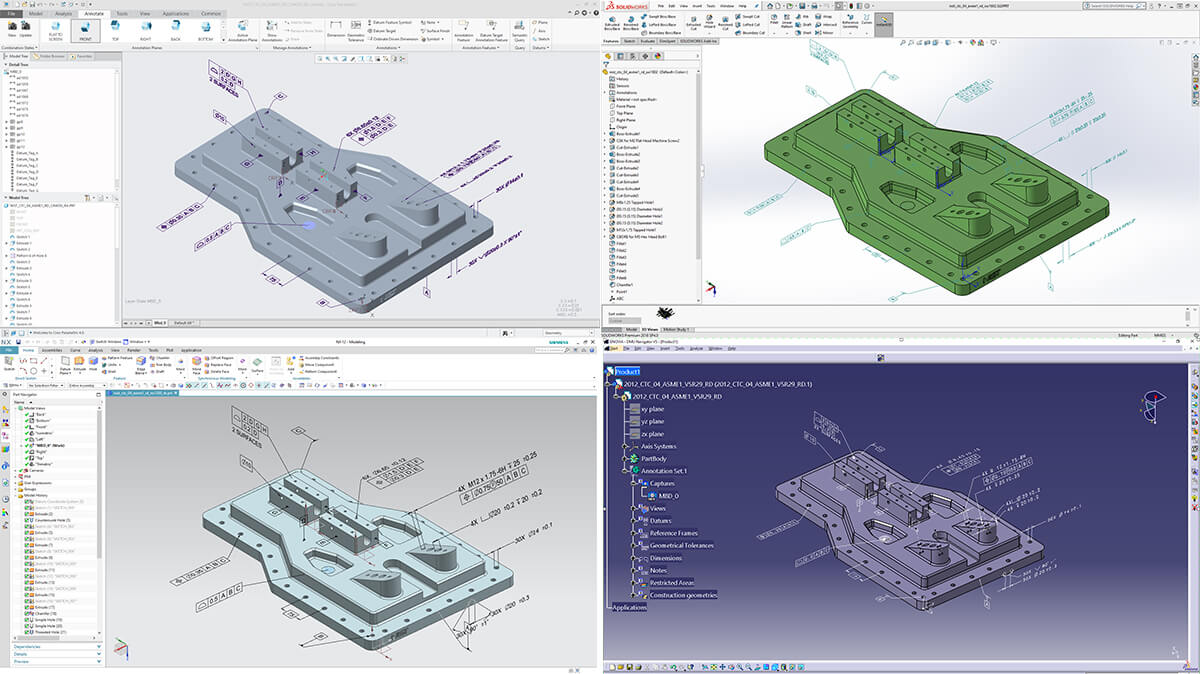

CompareVidia is an easy-to-use application for validating and comparing CAD models. A simple workflow enables you to load two CAD models and compare them based on your criteria. Models are classified as either PASSED or FAILED. A report is automatically generated to digitally certify compliance with standards like Boeing’s D6-51991 “Quality Assurance Standard for Digital Product Definition”.

The preferred solution for leading manufacturers, CompareVidia delivers an efficient, powerful, and automatic way to validate CAD model integrity at different stages of the digital product life cycle.

Find out how and why to implement Model-based definition (MBD).

Visit the dedicated section

Find out how and why to implement the "Dimensional Management" method.

Visit the dedicated section

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

In a recent interview, Enrico Boesso (EnginSoft) and Daniel Campbell (Capvidia) discussed how Model-Based Definition (MBD) is transforming manufacturing by replacing traditional 2D drawings with data-rich 3D models as the "single source of truth".

comparevidia mbdvidia tolerances digital-manufacturing mechanics

training courses

The training course on geometric product specification and tolerance analysis addresses the issues related to tolerance management and the approach known as "Dimensional Management", which defines the activities involved and their sequence for achieving the desired quality at the lowest possible cost. We offer a wide range of training courses – scheduled, on-demand and customized – designed to meet the varying needs of individuals and/or the company in which they work: SO-GPS, ASME-GD&T standards, Tolerance analysis and model-based definition, and Software technologies training.

cetol tolerances

CASE STUDY

In a recent interview, Enrico Boesso (EnginSoft) and Daniel Campbell (Capvidia) discussed how Model-Based Definition (MBD) is transforming manufacturing by replacing traditional 2D drawings with data-rich 3D models as the "single source of truth".

comparevidia mbdvidia tolerances digital-manufacturing mechanics

CASE STUDY

This article is the first part of a four-part mini-series exploring key aspects of modern tolerance management in product development. It focuses on Dimensional Management (DM) — a simulation-based engineering methodology essential for ensuring dimensional quality across a product’s lifecycle.

tolerances mbdvidia comparevidia gdtadvisor cetol

CASE STUDY

This article explores the practical implementation of Geometric Dimensioning and Tolerancing (GD&T) according to the ISO GPS standards, focusing on the functional definition and consistent application of Datum Reference Frames (DRFs). DRFs, derived from a component’s functional geometry and assembly sequence, constrain six degrees of freedom to ensure stable alignment and reproducibility during production and assembly.

tolerances mbdvidia comparevidia gdtadvisor cetol