ACCURATE

ACHIEVING RESILIENCE THROUGH MANUFACTURING AS A SERVICE, DIGITAL TWINS AND ECOSYSTEMS

Smart Manufacturing

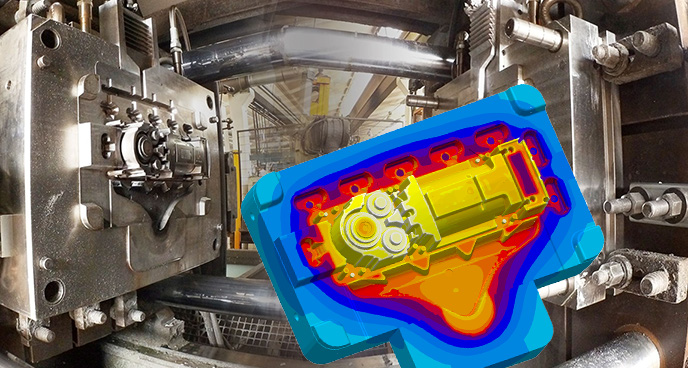

The ACCURATE project aims to boost the competitiveness of European manufacturing companies and value chains by improving their sustainability, performance stability, resilience, and ability to manage unforeseen events.

ACCURATE will develop innovative approaches and deliver an integrated set of results, culminating into:

ACCURATE results will be validated in 3 pivotal use cases covering multiple key European industrial sectors and value networks (aerospace, automotive, biotech, energy, medical, mobility).

ACCURATE will exploit the transformative potential of data spaces and ecosystems in revolutionizing business models and value propositions and will leverage these technologies and approaches to achieve impact, create resilient manufacturing networks, instigate deep innovation and accelerate results adoption.

ES is the Scientific Coordinator of the project. Moreover, EnginSoft is responsible for the design and development of the ACCURATE human-centered decision-support systems (DSS). To this end, ES provides its expertise in data analytics and data modelling applied to manufacturing processes, mathematical modelling, AI and ML, data- and simulation-driven development of process/ system levels digital twins and optimization. Furthermore, ES will implement the modelling of unforeseen disruptive events and the Multi-level analysis of cause-effects propagation on supply chains.

SOFTWARE IMAGINATION & VISION SRL | AARHUS UNIVERSITET | AIRBUS ATLANTIC | CONTINENTAL AUTOMOTIVE ROMANIA SRL | DELTADAO AG | ELECTRONIQUE INDUSTRIELLE DE L'OUEST - TRONICO SAS | ENGINSOFT SPA | FRAUNHOFER GESELLSCHAFT ZUR FORDERUNG DER ANGEWANDTEN FORSCHUNG EV | HOCHSCHULE FUR WIRTSCHAFT UND RECHT BERLIN | INSTITOUTO ANAPTIXIS EPICHEIRIMATIKOTITAS ASTIKI ETAIREIA | INSTITUT MINES-TELECOM

HORIZON-RIA - HORIZON Research and Innovation Actions | Call identifier: HORIZON-CL4-2023-TWIN-TRANSITION-01-07 - Achieving resiliency in value networks through modelling and Manufacturing as a Service (Made in Europe Partnership)

Some of our competences in research and technology transfer

Research project

The LIFESAVER addresses the presently unmet societal and healthcare needs in creating and developing of a validated scientific knowledge base for the development and implementation of regulatory approaches relevant to maternal and fetal health.

Research project

The PreMANI project aims to demonstrate the applicability of these techniques across disparate application domains, characterized by very different needs, by leveraging methodological aspects of a general nature.

Research project

The project supports some of the companies within the SINFONET network in using high value services, assistance, orientation, coaching, information, and export promotion to promote not only their individual companies but also the overall foundry supply chain.