From a structural point of view, the aerospace industry requires integrity of each component at many different operating points, from take-off/landing to the upper atmosphere to outer space, where thermal gradients on satellites are extreme and greatly affect structural calculations. In this regard, explicit dynamics simulation has become standard practice when investigating the effect of bird strike on an engine, evaluate blade containment strategies for fan blade out, or investigate the reasons for structural failure on a specific component. As today’s civil aerospace industry accounts for about 2% of the worldwide CO2 production, a lot of research is taking place to develop lighter structures employing composite materials, in order to save weight, consume less fuel and therefore reduce the overall environmental impact.

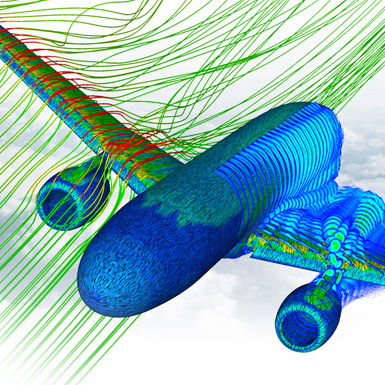

For the same reasons, new solutions for civil engines have been developed, allowing them to become more efficient in terms of fuel consumption thanks to advanced CFD modeling techniques, applied to fuel injection and cooling systems, combustion chambers and augmentor design. Aerodynamics is also an important topic of research in order to develop high-lift, efficient wing profiles both for cruise and take-off/landing operating conditions. Aerodynamic noise is also relevant here: CFD codes coupled with an acoustic solver have created a new discipline called CAA (Computational Aero Acoustic) to predict aero-acoustic noise. Another coupling takes place when CFD joins FEM in Fluid Structure Interaction (FSI), often employed to calculate the flutter phenomenon, as well as the rotor-dynamics of helicopters.

Electronic components have a high impact on the cost of aircrafts and helicopters. Therefore the field of Electromagnetism is very important for the aerospace market, as many devices can cause interference problems (we all need to turn off our mobiles at take-off and landing after all) and antennas signal integrity must be assured for navigational purposes. Finite Element Analysis and CFD is often employed for analyzing the stress/strain field on electronic components, deriving from dynamic loads as well as thermal gradients.

As aerospace is a mature industry, many components generally have had a long development history and are quite reliable and performing. Yet, the development of new, innovative technologies, along with the strife for continuous improvement of existing parts, makes FEM or CFD or EM calculations alone not enough. The real challenge is to integrate all of these technologies in a design and optimization process such as PIDO (Process Integration and Design Optimization). This is where the CAE market is moving, and that is where partnering with EnginSoft can make a real difference for your company.

Some notable research/projects we have been working on lately and our areas of expertise are here reported.

research

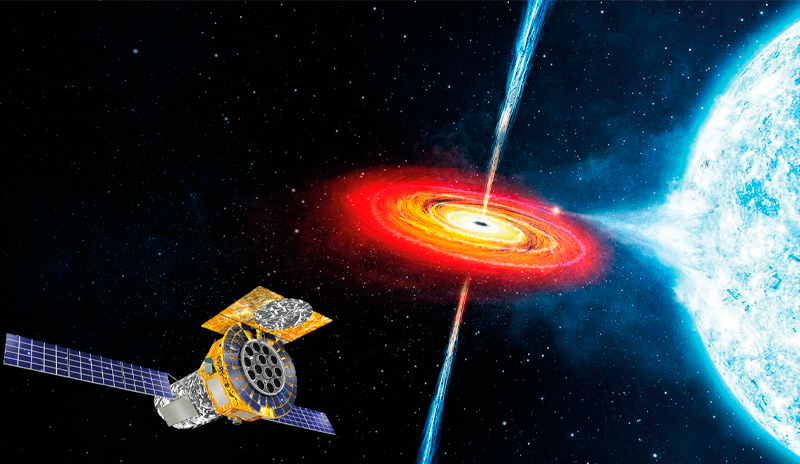

EnginSoft has been a key participant in MELiSSA (Micro Ecological Life Support System Alternative) and ALISSE (Alternative Life Support System Evaluator) research projects, to develop the technology required for a future biological life support system for long term manned space missions, sponsored by the European Space Agency ESA; has performed thermo-structural analysis for satellite electronics housing using ESAComp (a software for the design of composite structures, developed by Componeering, a company co-founded by EnginSoft); performed explicit dynamics simulations to optimize airbag deployment on the ExoMars rover.

research

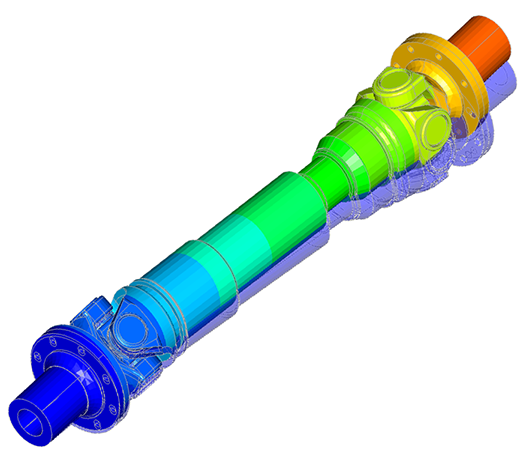

Structural optimization of composite wings; turbine inlet design and optimization; aeroacoustics of jet engines; multi-phase fluid modeling and spray atomization; design of aeroengines components such as combustors, high- and low- pressure turbines, gear pumps and breathers; bird strike and fan blade out analysis.

CASE STUDY

Gambacciani began his career in development of diesel engines at FIAT-GM Powertrain (now FCA) where he gains a solid experience on CAE both in the fluid and structural environment.

aerospace ls-dyna

CASE STUDY

The challenge was to find the optimal aerodynamic design while substantially reducing the costs associated with traditional CFD modeling.

aerospace cfd ansys

CASE STUDY

This project investigates how best to correctly predict the energy absorption of these non-isotropic and non-homogeneous materials, whose lamina thickness is typically of the order of 0.2 mm or less and consists of tiny fibers or particles dispersed in a matrix material.

ls-dyna aerospace composites

CASE STUDY

This paper presents the design and first experimental results of a very compact Ku-band bandpass filter for high power satellite applications. The filter was designed and simulated using the Ansys HFSS and Mechanical simulators. Proposed as part of an ESA ARTES Advanced Technology project, the filter is based on dielectric loaded combline resonators.

ansys electronics aerospace

CASE STUDY

This technical article describes a new, automated approach to accurately and robustly morph CAD geometry based on results of analysis in order to facilitate the missing bi-directional transfer of these geometries between analysis/test/manufacture and design. Two industrial examples using this approach are also provided, in the morphing of a turbine blade deformation model and aero-elastic deformation of aerodynamic shapes for the NASA Common Research Model.

aerospace

CASE STUDY

This article describes the preliminary study resulting in the design solutions adopted for the LAD module’s most important thermo-mechanical drivers, which were developed and used to demonstrate compliance with the system requirements at the spacecraft level.

aerospace rbf-morph ansys

CASE STUDY

This project has been coordinated by the German Aerospace Center (DLR) and it is embedded in the MELiSSA framework of ESA research projects.

aerospace cfd ansys

CASE STUDY

The residual strength, in particular the compression strength after damage due to low velocity impact, is one of the most critical issue for composite laminates.

ls-dyna aerospace modefrontier composites

CASE STUDY

Pipistrel, an aviation and aerospace company based in Slovenia, chose ESTECO technologies to design the propeller for a highly efficient, hybrid-electric aircraft.

aerospace modefrontier

CASE STUDY

The aerospace industry is embracing a cutting-edge workflow that combines virtual reality (VR), reduced order models (ROMs), and mesh morphing to revolutionize aerodynamic design. Developed through a collaboration between the University of Rome Tor Vergata and RBF Morph, this approach allows engineers to explore and adjust designs in real time within an immersive 3D VR environment

aerospace rbf-morph vrd

CASE STUDY

Menet Aero worked with Wolf Star Technologies to implement the True-Load load reconstruction software on their hexacopter drone. This project allowed Menet Aero to acquire valuable data on their drone designs, which can be used to optimize the weight and cost of their aircraft. The True-Load methodology proved to be an efficient and effective use of FEA models and testing techniques, providing a small investment in strain gauges for mission-critical data.

aerospace trueload

CASE STUDY

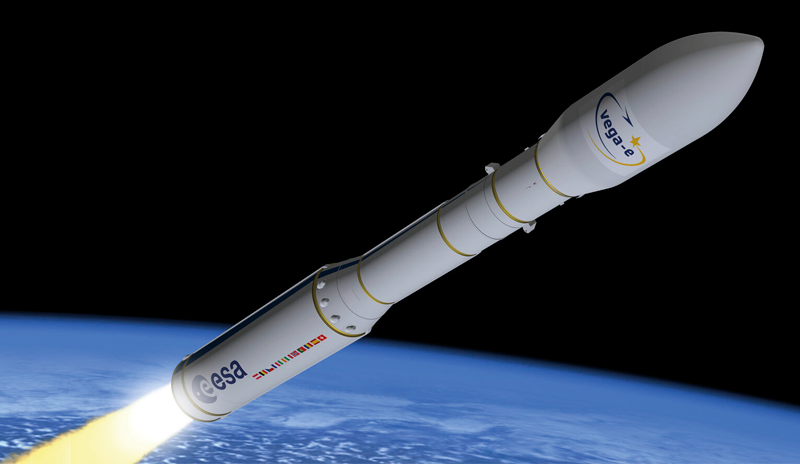

This article is based on a collaboration between RBF Morph and AVIO to configure a numerical optimization procedure to improve the Vega E M10 engine’s performance by optimizing the methane circuit of the injector head.

aerospace rbf-morph ansys meshing