Fiix CMMS

Having trouble with maintenance?

Simplify your journey to modern asset maintenance

Fiix CMMS is a product of Rockwell Automation

Fiix CMMS is a product of Rockwell Automation

Whether you want to organize assets and manage maintenance, or connect to enterprise systems and make data-driven decisions, Fiix CMMS works with you to provide the tools to move from reactive to preventive maintenance and beyond.

Fiix CMMS (Computerized Maintenance Management System) is the CMMS from Rockwell Automation that helps reduce downtime, cut maintenance costs and increase productivity.

The rich feature set and automatic relationships among information allow for a shorter implementation time and cost reduction.

Designed to scale with large and complex industrial operations, it can handle massive volumes of data, providing a unified and complete view of business operations.

Comprehensive reporting allows you to capitalize on available data and enable data-driven management of maintenance processes.

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

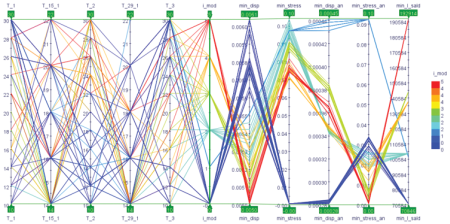

In this technical article, Fiat Chrysler Automobiles explain how they created a multibody optimization project to identify the optimal values for the powertrain suspension stiffness for a three-cylinder engine in order to minimize the vibrations at idle condition and ensuring greater ride comfort to the passengers.

automotive optimization modefrontier

CASE STUDY

The text discusses the importance of digital simulation models in modern factory design and reconfiguration, particularly in response to shorter product lifecycles and increased customization demands. Traditional design methods often lead to inefficiencies and high costs, making digital simulation essential for creating flexible and adaptable production systems. The article highlights a case study involving a furniture assembly factory, where a manufacturer needed to efficiently handle a variety of custom kitchen cabinet orders. The system integrator was tasked with designing a robotic assembly line that could maintain production efficiency despite the high variety of products.

industry4 SIMUL8

CASE STUDY

ECM Technologies has significantly streamlined the design, installation, and commissioning of its large-scale heat treatment systems for the automotive industry by using digital twin technology and Rockwell Automation’s Emulate3D software. Faced with tight timelines and software compatibility challenges during a major project in Mexico, ECM used virtual models to simulate and test their systems in parallel with production. This approach reduced commissioning time by 50%.

digital-manufacturing emulate3d industry4 rockwell

CASE STUDY

Elettronica SpA designs and produces systems for electronic warfare. Each system design is unique according to its platform and purpose. In this article, the company describes how it used CAE to approach the challenging design of a single sandwich radome.

ansys optimization electronics

CASE STUDY

This technical article describes how engineers tackled a design optimization challenge to ensure the structural integrity of a section of the beam of a typical steel bridge whose web of main beams was subject to instability.

civil-engineering modefrontier optimization