Monarch Classic and Monarch Data Prep Studio

Prepare, Transform, and Cleanse Data from Virtually Any Source

Monarch is a product of Altair

Monarch is a product of Altair

Altair Monarch Classic is a comprehensive application enabling users to model and extract analytical assets from diverse data sources, including structured and unstructured formats like PDFs, reports, and EDI streams. This data can then be utilized for self-service desktop analytics.

Data Prep Studio, a component of Monarch, facilitates rapid data preparation with features such as drag-and-drop parsing and extraction, report discovery and data combination, real-time data manipulation, and export capabilities to various file types.

Designed for data architects, engineers, and analysts, Monarch simplifies data transformation with a wizard-driven interface and over 80 pre-built functions. Models can be seamlessly exported to popular BI and analytics platforms.

With 30 years of industry leadership, Monarch excels at extracting data from diverse sources, including PDFs, text files, and big data. Ensure data integrity with auditable change histories and clear lineage tracking, all without coding.

Empower self-service data preparation on the desktop, eliminating IT bottlenecks. Automate repeatable processes with reusable models, freeing up valuable time for analysis.

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

This paper presents the RENAULT F1 Team’s AM process for an aerodynamic insert in titanium Ti6Al4V. Production was optimized by identifying the best orientation for the parts and the best positioning for the support structures in the melting chamber, in addition to using the ANSYS Additive Print module, a simulation software useful for predicting the distortion of a part and for developing a new, 3D, compensated model that guarantees the best “as-built” quality.

automotive additive-manufacturing optimization

CASE STUDY

The text discusses the importance of digital simulation models in modern factory design and reconfiguration, particularly in response to shorter product lifecycles and increased customization demands. Traditional design methods often lead to inefficiencies and high costs, making digital simulation essential for creating flexible and adaptable production systems. The article highlights a case study involving a furniture assembly factory, where a manufacturer needed to efficiently handle a variety of custom kitchen cabinet orders. The system integrator was tasked with designing a robotic assembly line that could maintain production efficiency despite the high variety of products.

industry4 SIMUL8

CASE STUDY

The text discusses the importance of digital simulation models in modern factory design and reconfiguration, particularly in response to shorter product lifecycles and increased customization demands. Traditional design methods often lead to inefficiencies and high costs, making digital simulation essential for creating flexible and adaptable production systems. The article highlights a case study involving a furniture assembly factory, where a manufacturer needed to efficiently handle a variety of custom kitchen cabinet orders. The system integrator was tasked with designing a robotic assembly line that could maintain production efficiency despite the high variety of products.

industry4 SIMUL8

CASE STUDY

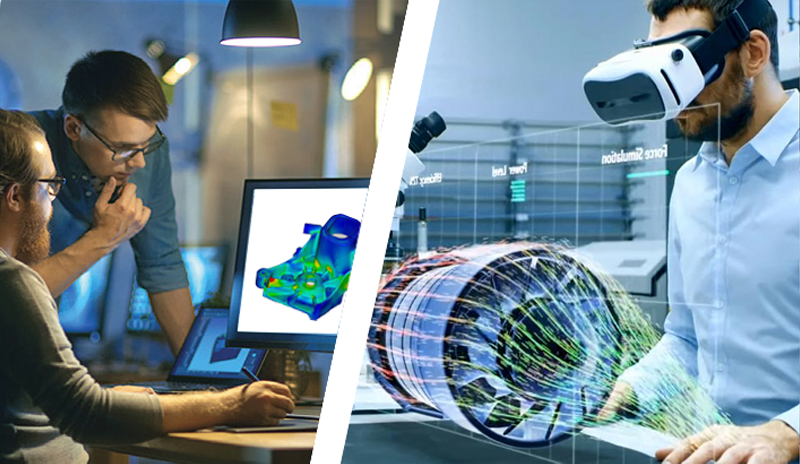

At this particular moment in time, this article wishes to reflect on the evolution of CAE and simulation in an effort to present a big-picture view when most of us are daily dealing with all the devil in the details in every aspect of our lives. We approached some long-standing business friends in engineering simulation from various regions around the world to help us in this task

ansys industry4 news

CASE STUDY

Elettronica SpA designs and produces systems for electronic warfare. Each system design is unique according to its platform and purpose. In this article, the company describes how it used CAE to approach the challenging design of a single sandwich radome.

ansys optimization electronics