RaRe2

Human-centred Rapid Reconfiguration of Production and Value Chains in Fast Changing Scenarios

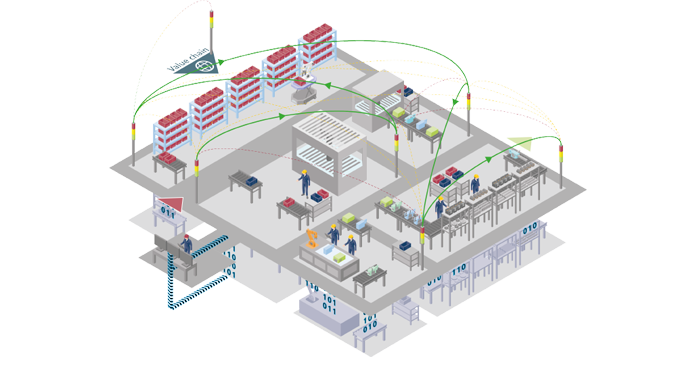

Smart manufacturing

The overall objective of the RaRe2 project is to create a flexible and resilient Holistic Ecosystem Platform powered by the interactions of many European organizations interested in cooperating in the rapid reconfiguration of process chains through collaborative systems and adaptive workforce up-skilling. The strategic objectives of the project include:

The project will introduce a smart connection of sustainable and digitized manufacturing solutions to enable rapidly reconfigurable and crisis-resilient manufacturing systems that are able to quickly reach full production speed for the new products demanded by society and customers. RaRe2 will help make the European manufacturing landscape sustainably resilient to unforeseen market changes, sudden disruptions, regulatory changes, or any kind of crisis and changeable scenario including climate and weather.

It will be powered by interaction among many European organizations interested in collaborating on rapid reconfiguration of process chains through COLLABORATIVE SYSTEMS and ADAPTABLE WORKFORCE UP-SKILLING.

RaRe2 introduces the smart connection of sustainable and digital manufacturing solutions to enable rapidly configurable and crisis-resilient manufacturing systems. RaRe2 features innovations in eight areas: 1) Industry-specific early detection software; 2) Standardized system-level digital manufacturing twin; 3) Standardized digital logistics twin at system level; 4) Automatic generation and simulation of alternative value chains; 5) Skills gap detection and methods for standardizing reconfigurable training; 6) Reconfigurable mixed-reality assistance and training for manual workstations; 7) Holistic Modular ecosystem platform for rapid interactive decision support; 8) Certification standard.

EnginSoft is responsible for the generation and simulation of alternative value chains.

Fraunhofer IWU EV | AIT - Austrian Institute of Technology GmbH | BIBA - BREMER INSTITUT FUER PRODUKTION UND LOGISTIK GmbH | CORE Kentros Kainotomias Amke, Demcon Industrial Systems Groeningen BV | EnginSoft SpA | ErreQuadro Srl | EWF - European Federation for Welding | Joining and Cutting | Fontana Pietro SpA | L. Karwala SK | LSE - Lightweight Structures Engineering GmbH | MMM Healthcare International GmbH | Politecnico di Milano | ProFactor GmbH | Q4Pro sp. z.o.o | Recendt GmbH | RINA Consulting SpA | R2M Solution Srl | Symate GmbH | Syxis VSI | Thermoglass.eu sp. z.o.o

Funding Scheme This project has received funding from the European Union’s Horizon Europe research and innovation programme under Grant Agreement No. 101092073 | Call identifier HORIZON-CL4-2022-TWIN-TRANSITION-01-01

42 months

December 2022 – May 2026

Fraunhofer IWU

Giovanni Paolo Borzi, Anteneh Teferi Yemane

21

Some of our competences in research and technology transfer

Research project

The core of this project is the development of a trade-off study, meant to compare several different structures incorporating new technologies, in order to determine the most promising solutions among those considered

Research project

The overall objective of the TECNOMED-HUB project is to create, in the Piedmont region of Italy, a technology platform to support medical research 4.0, based on the integration of existing multi-omics platforms with self-learning algorithms, data mining, and big data analytics.

Research project

The SIADD project aims to increase the manufacturing quality and sustainability of some additive manufacturing processes for metals, composite materials and multi-material metals/ composites, while also taking into account the personnel’s economic and environmental conditions and well-being.