Panopticon

Comprehensive Data Visualization and Streaming Analytics

Panopticon is a product of Altair

Panopticon is a product of Altair

In time-sensitive industries like manufacturing, finance, healthcare, and energy, delayed decisions are costly. Relying on end-of-day reports risks missed opportunities and slow responses to critical threats.

Panopticon empowers business users, analysts, and engineers to build, modify, and deploy real-time data visualization and stream processing applications with a simple drag-and-drop interface.

Connect to any data source, from big data to message queues, and design custom dashboards for immediate, informed decision-making.

Deep data insights & comprehensive operational views. Secure dashboard & report sharing.

Point-and-click application & dashboard creation. Rapid response to business changes.

Automated chart generation & ML-driven models. Complex dataset visualization.

High-velocity stream processing & historical comparisons. Nanosecond timestamp precision & data replay.

Customizable alerts via multiple channels. Alerts based on streaming & historical data.

Seamless integration into business applications. Single sign-on (SSO), embed link generation & cross-origin resource sharing (CORS) support.

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

This detailed technical case study describes how the students arrived at a supersonic aircraft drone prototype using MATLAB and modeFRONTIER in order to reduce the time and costs of numerical and wind-tunnel testing.

automotive modefrontier optimization

CASE STUDY

The text discusses the importance of digital simulation models in modern factory design and reconfiguration, particularly in response to shorter product lifecycles and increased customization demands. Traditional design methods often lead to inefficiencies and high costs, making digital simulation essential for creating flexible and adaptable production systems. The article highlights a case study involving a furniture assembly factory, where a manufacturer needed to efficiently handle a variety of custom kitchen cabinet orders. The system integrator was tasked with designing a robotic assembly line that could maintain production efficiency despite the high variety of products.

industry4 SIMUL8

CASE STUDY

This paper explores the transformative potential of Extended Reality (XR)—encompassing Virtual Reality (VR), Augmented Reality (AR), and Mixed Reality (MR)—when integrated with Artificial Intelligence (AI) in industrial and engineering applications. XR technologies enable businesses to visualize, interact, and optimize product designs, training processes, and customer support functions.

digital-manufacturing optimization artificial-intelligence

CASE STUDY

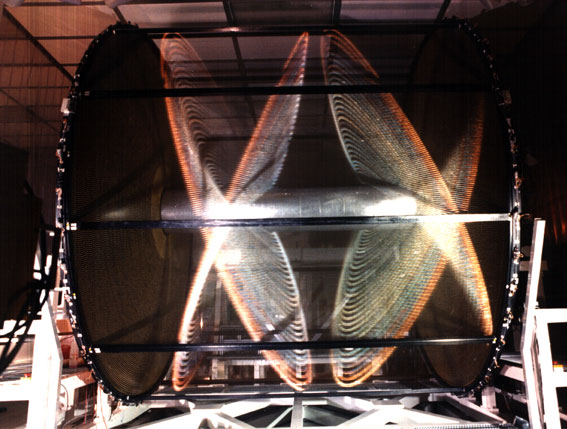

The ultimate goal of the study was to optimize the Drift Chamber’s performance in terms of stiffness, strength and weight o be mounted on the Mu2e particle detector at FermiLAB in Chicago

construction modefrontier ansys optimization energy

CASE STUDY

The main structure of the yacht is made of composite laminates with the presence of many composite reinforcements and bonded joints. We conducted a detailed structural analysis of the entire structure and verified the structural requirements.

marine optimization