Scientific and technological

innovation

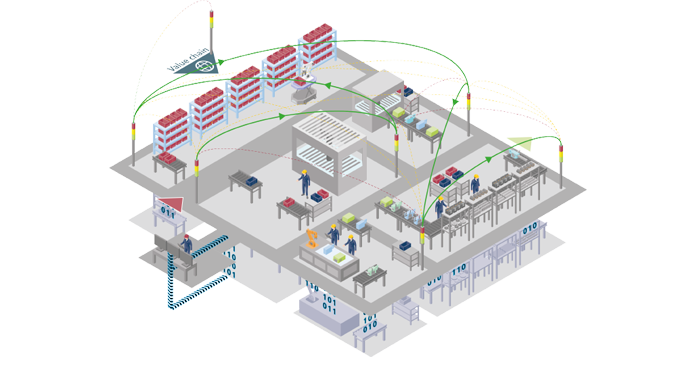

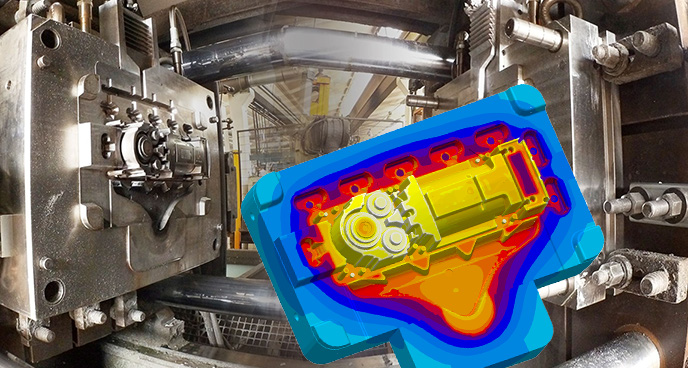

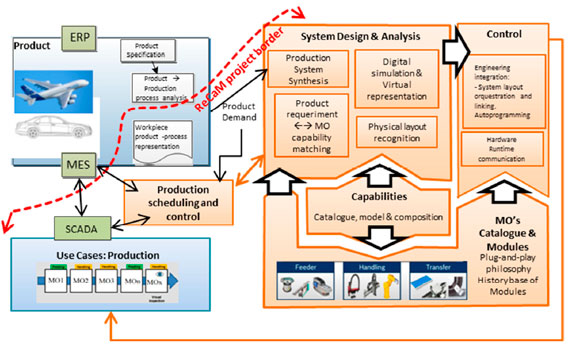

By participating in research and innovation projects, we increase our ground-breaking technical knowledge day by day and deepen our expertise in new areas, innovating and trialling new SBES (Simulation-based Engineering and Sciences) software, applications, and technologies.

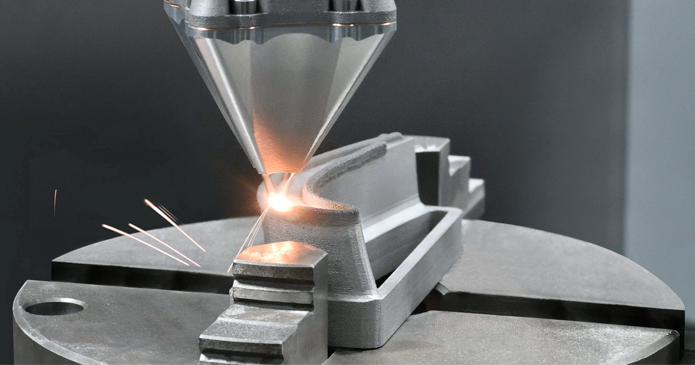

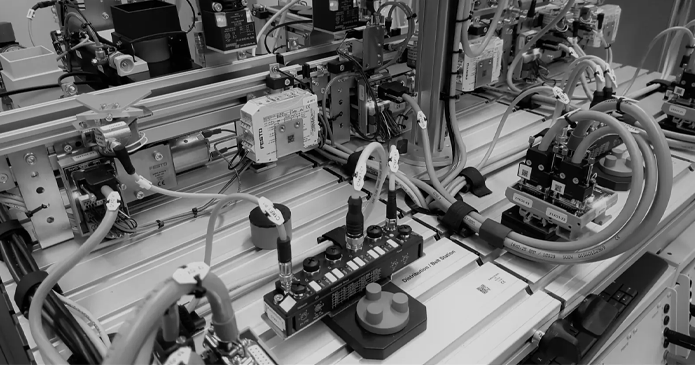

We contribute to research initiatives by providing expertise in Multiphysics product and process simulation and manufacturing system simulation.

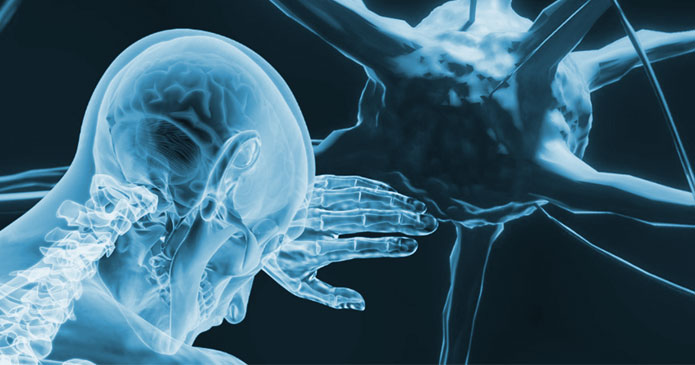

Our capabilities in data management and analysis, mathematical modelling, the data- and simulation-driven development of digital twins and decision-support systems (DSS) applied in diverse industrial domains and processes complement and add value to Multiphysics simulation results.