PLEX

PLEX is a product of Rockwell Automation

PLEX is a product of Rockwell Automation

The Plex Smart Manufacturing Platform is a digital system of record that connects people, systems, machines, and supply chains; automates business processes; tracks data from the shop floor to the top floor; and delivers analytics for unmatched visibility, quality, and control.

Plex is a cloud-based software as a service that is offered in modules to allow manufacturers the opportunity to respond to many business challenges. The modules included in the platform include:

These modules can be implemented individually, as integrated components, or as a whole.

Plex operates private data centers in the US which offer the full stack of Plex capabilities, with additional private data centers being added in APAC in 2024. Plex also operates Microsoft Azure-based public cloud data centers in Dublin and Amsterdam in Europe that offer Plex full MES capabilities.

PLEX helps manufacturing companies:

Furthermore, PLEX is the ideal solution for companies that want to leverage the benefits of the cloud to integrate and harmonize the management of multiple geographically separate production or logistics plants.

PLEX maximizes customer value thanks to top-notch features and a low TCO.

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

The text discusses the importance of digital simulation models in modern factory design and reconfiguration, particularly in response to shorter product lifecycles and increased customization demands. Traditional design methods often lead to inefficiencies and high costs, making digital simulation essential for creating flexible and adaptable production systems. The article highlights a case study involving a furniture assembly factory, where a manufacturer needed to efficiently handle a variety of custom kitchen cabinet orders. The system integrator was tasked with designing a robotic assembly line that could maintain production efficiency despite the high variety of products.

industry4 SIMUL8

CASE STUDY

The text discusses the importance of digital simulation models in modern factory design and reconfiguration, particularly in response to shorter product lifecycles and increased customization demands. Traditional design methods often lead to inefficiencies and high costs, making digital simulation essential for creating flexible and adaptable production systems. The article highlights a case study involving a furniture assembly factory, where a manufacturer needed to efficiently handle a variety of custom kitchen cabinet orders. The system integrator was tasked with designing a robotic assembly line that could maintain production efficiency despite the high variety of products.

industry4 SIMUL8

CASE STUDY

This article discusses a realistic multi-objective parameter optimization study of a highly athletic one-legged robot, called Skippy, in which both the parameters of the mechanism and the parameters of its optimal behaviors were sought.

optimization modefrontier biomechanics

CASE STUDY

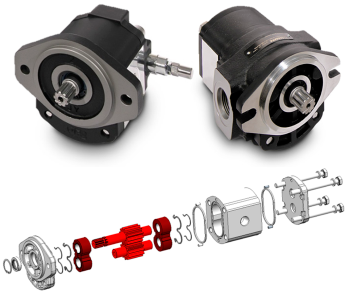

In this technical case study, EnginSoft assists Casappa to further refine an already-optimized standard series pump for an electrical motor and generator

mechanics optimization modefrontier

CASE STUDY

This study was part of the Virtual Optimization PAsta production process (OPAV) research project,

modefrontier ansys ls-dyna magma optimization food-beverage consumer-goods