MBDVidia

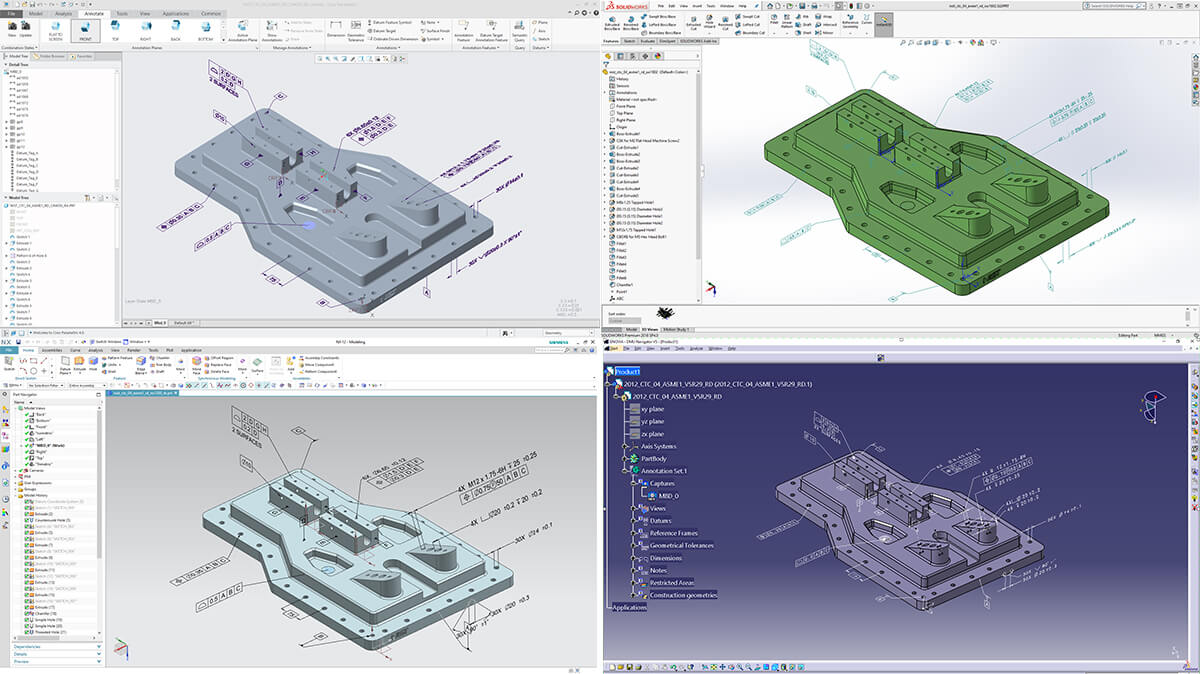

MBD Workflow & CAD Translation

MBDVidia is a product of Capvidia.

MBDVidia is a product of Capvidia.

Your valuable native cad data is now open for use and re-use in any environment. True MBD: 3D CAD + PMI that is human & machine-readable.

Your authority cad model effortlessly flowing downstream:

Find out how and why to implement Model-based definition (MBD).

Visit the dedicated section

Find out how and why to implement the "Dimensional Management" method.

Visit the dedicated section

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

In this technical case study, we illustrate how EnginSoft engineers helped ABB to optimize the design of the Emax2 project.

tolerances electronics mechanics eztol cetol

training courses

The training course on geometric product specification and tolerance analysis addresses the issues related to tolerance management and the approach known as "Dimensional Management", which defines the activities involved and their sequence for achieving the desired quality at the lowest possible cost. We offer a wide range of training courses – scheduled, on-demand and customized – designed to meet the varying needs of individuals and/or the company in which they work: SO-GPS, ASME-GD&T standards, Tolerance analysis and model-based definition, and Software technologies training.

cetol tolerances

CASE STUDY

This article is the first part of a four-part mini-series exploring key aspects of modern tolerance management in product development. It focuses on Dimensional Management (DM) — a simulation-based engineering methodology essential for ensuring dimensional quality across a product’s lifecycle.

tolerances mbdvidia comparevidia gdtadvisor cetol

CASE STUDY

Special Springs commissioned EnginSoft’s engineers to calculate the production cost repercussions of a technical product modification requested by an important customer.

eztol mechanics cetol tolerances

CASE STUDY

This case study describes ISEO’s project to introduce a global dimensional management approach based on CETOL6σ that starts from the product concept phase and includes design development and prototyping and extends on to cover all other phases of production through to the finished product, with the guidance and support of EnginSoft.

tolerances cetol mechanics