Particleworks

An advanced CFD Software solution, based on the Moving Particle Simulation (MPS) method

Particleworks is a product of Prometech.

Particleworks is a product of Prometech.

Particleworks is an advanced CFD Software solution, based on the Moving Particle Simulation (MPS) method.

Distributed by EnginSoft across Europe, Particleworks provides significant time and cost savings by eliminating the mesh generation that is required for conventional CFD software.

With Particleworks, engineers are able to model and simulate large-scale problems without overwhelming resources.

For CFD Users, Particleworks can help you achieve faster, better process with reduced resource comsumption.

For Engineers relying on tests because traditional CFD is taking too long, complex and resource demanding. Particleworks can help you save money through CAE simulation.

brochure

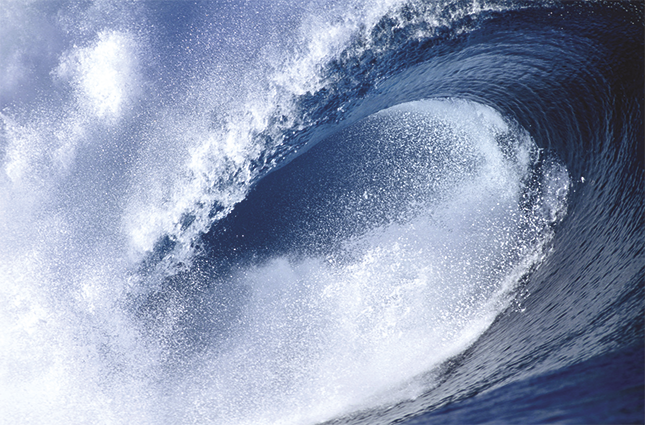

Moving Particle Simulation (MPS) is a meshless method of Computational Fluid Dynamics (CFD) specifically conceived to analyse liquid flows, from the most common liquids like water and oil, to the most complex ones such as highly viscous consumer products, adhesives, polymers, and foods or even semi-solid materials like grease or organic waste.

This publication is a collection of papers addressing different industrial sectors and covering applications ranging from lubrication of transmissions, cooling of engines, prevention of aquaplaning, and fire extinguishing, to the electrification of mobility solutions and the study of snow drifts.

Particleworks

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

Transmission design is mainly based on the mechanical aspects of the transmission and lubrication is an aspect that is verified, and eventually corrected, based on bench testing, i.e. once the design phase has been completed and a physical prototype is available.

mechanics particleworks automotive

CASE STUDY

In this technical article, we demonstrate how to apply a one-way coupling technique using a combination of ParticleWorks and LS-DYNA to estimate tsunami damage to a vehicle.

automotive ls-dyna energy cfd particleworks environmental

CASE STUDY

In this paper, we will present the methodology developed by TotalEnergies and EnginSoft to select, design and improve an e-motor by simulating and predicting electromagnetic losses, fluid flow behaviour and temperature distributions.

automotive electronics particleworks

CASE STUDY

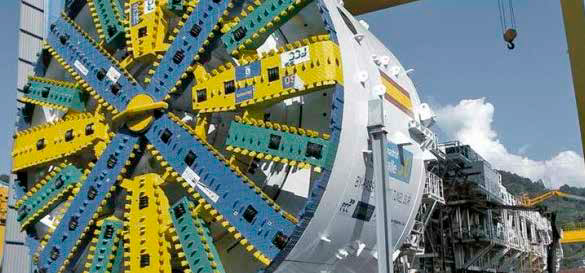

This technical article presents the study of a radial piston hydraulic motor with an outside cam arrangement for Bosch Rexroth Mellansel AB.

turbomachinery cfd particleworks

CASE STUDY

In this case study, LION Corporation uses Particleworks to simulate fluid flow to improve the design of a new cap spout for its new HARETA brand of laundry detergent.

particleworks cfd consumer-goods mechanics