EnginSoft has 40 years' experience in engineering consultancy and technology transfer and an active track record of over 100 co-funded projects at European, national and regional level.

Since 1998, we have been collaborating and coordinating co-funded projects, often in a strategic role, which has enabled us to be recognized by the European Commission as a Key Innovator and by the MIUR (Italian Ministry of Instruction, Universities and Research) as a Technology Transfer Laboratory.

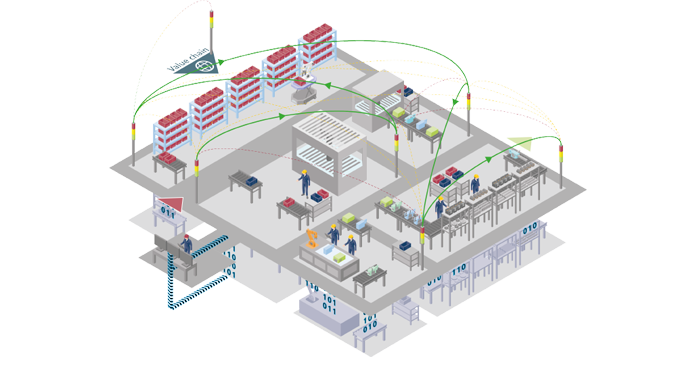

The team of experts in our Innovation & Technology Transfer unit offers companies its skills and experience in transforming new ideas into successful projects, covering the entire process: feasibility study of the project idea; monitoring of calls for proposals; partnership building; preparation and submission of the proposal; budget forecasting; and project management at every stage of progress up to final reporting.

The consulting service supports companies in their growth based on innovation and technology

transfer, identifying the most appropriate opportunities for the specific business

context and working with the client at all stages.