In technical drawings, geometric and dimensional tolerances

indicate the acceptable limits of mechanical variations in components.

These variations are unavoidable due to the inherent imperfection of all manufacturing and assembly

processes; they also tend to propagate within a product, often presenting amplification effects.

To avoid negative impacts on product requirements and functionality, variations should be managed

using Dimensional Management: this method is an essential part of the product

development process and is imperative for all companies wanting to maximize their profit margins

and competitiveness.

Optimal tolerance management is achieved through careful preliminary analysis and effective quality control strategies based on a rigorous approach to engineering, and effective collaboration between design, industrialization, production, supply chain, and quality control.

The objective is to BE PRECISE ONLY WHERE NECESSARY. This means that while the use of wide tolerances will make production processes more cost-effective, this is often at the expense of product performance/functionality; on the other hand, strict tolerances will guarantee high quality but negatively impact production costs. Finding a compromise is essential.

This requires:

- Standardized technical language

Providing technical documentation in a common language to facilitate clear and unambiguous communication between all parties involved in the product development process is key. This is now dictated by international standards and regulations such as ISO geometrical product specifications (GPS) and ASME geometric dimensioning and tolerancing (GD&T). - Tolerance analysis to calculate the tolerance chain and predict its impact on

product requirements

This is the only method currently available for assessing the amplitude values of the tolerances intended to be used in the design. It allows the potential risks of tolerances to be identified and resolved before the product is industrialized, simultaneously optimizing product value. The most important potential benefits include increased productivity, greater repeatability in assembly processes (essential to avoid frequent downtimes of automated assembly lines), less production waste, fewer non-compliances to be managed and resolved, minimization of repairs/rework, and so on.

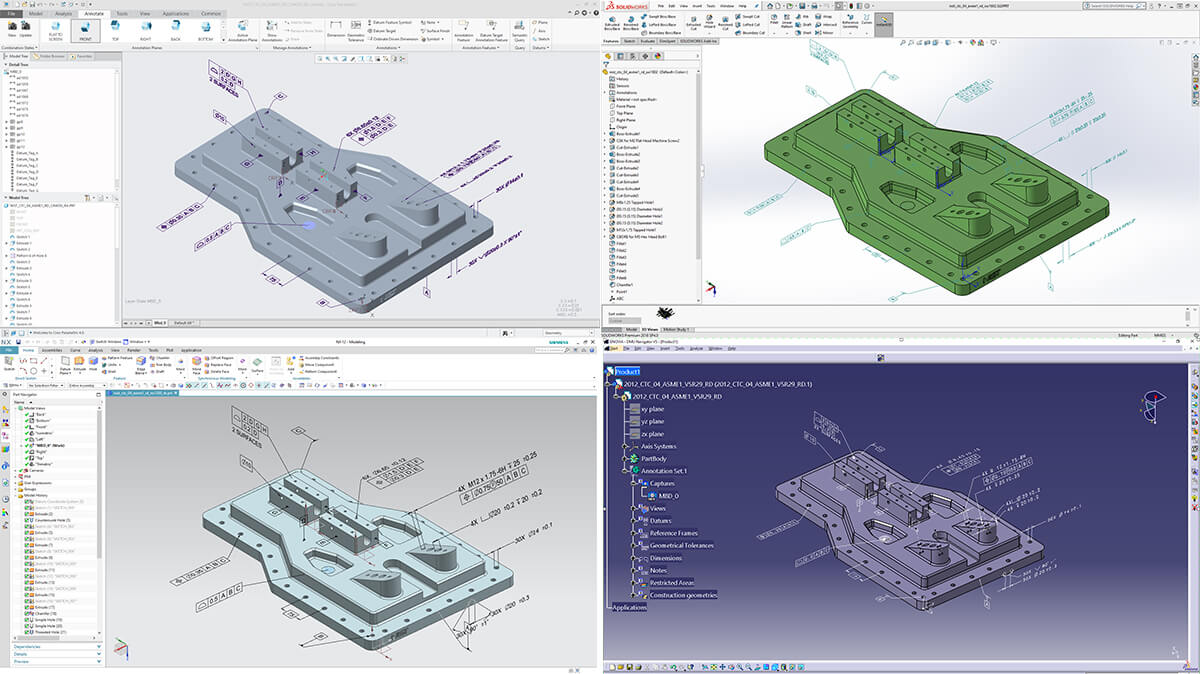

Moreover, this method and the various supporting tools are well-suited to use with the digitalization of all relevant product development information. By using new generic CAD interchange formats (STEP AP242 and/or QIF – Quality Information Framework), specifically introduced to support the radical digital transformation of manufacturing companies towards MBD (Model Based Definition), the various information steps between design, production, and quality control can be automated. This allows the full potential of new-generation industry 4.0 equipment to be fully leveraged, reducing human error in data transcription, and freeing time and resources to innovate products/processes rather than performing low-value tasks.

The stages of tolerance management

- Define product specifications based on functional requirements.

- Analyse the assembly process to identify: the interactions between different parts; the variability associated with different joint types (welded, glued, hole/shaft with/without play, etc.); and the tolerance chains.

- Assign tolerances, i.e. define the width of tolerances in the drawing to guarantee the required functionality and assembly requirements.

- Tolerance analysis, i.e. assess the impact of tolerances on product performance and assembly using dedicated analytical methods, spreadsheets, or CAT (Computer Aided Tolerancing) simulation software. The most frequently used approaches to analysis are worst-case or statistical. In this phase, product performance requirements are balanced against development cost assessments.

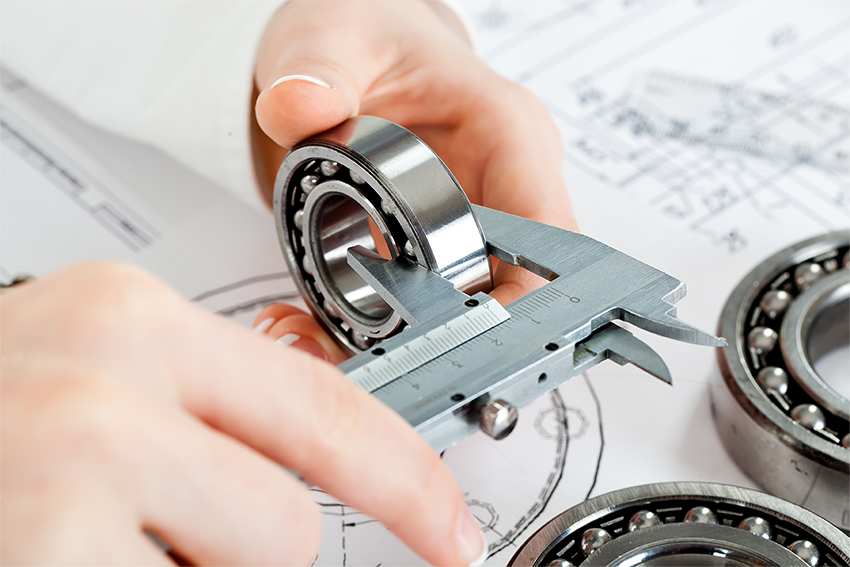

- Verify compliance, i.e. conduct dimensional checks to verify that the components meet the drawing specifications and are "in tolerance".

- Iterate and optimize, i.e. adapt the specifications, tolerances, or production processes as necessary if deviations or anomalies arise.