The EU’s Digital Europe Programme is based on key elements of Industry 4.0.

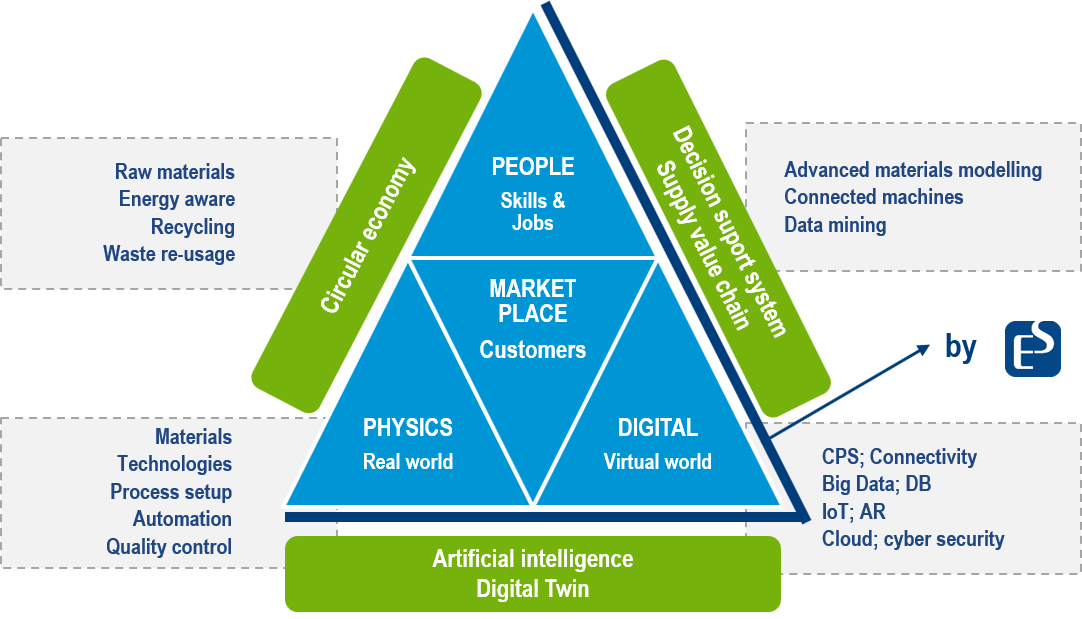

The PEOPLE, DIGITAL and Real PHYSICS worlds are key ingredients for the competitiveness and sustainability of a customer-oriented (the market place) Smart Factory.

EnginSoft invests in the human skills and competences to properly use Industry 4.0 tools. The company’s program of training and courses is integral to the transfer of knowledge to customers – some examples are its collaboration with European academic institutions and the TCN Consortium.

EnginSoft has digital in its DNA – right from the pioneering days of numerical modelling in the Eighties with CAE virtual prototyping.

A Decision Support System (DSS) along the value chain is mandatory to enable the effective adoption of Industry 4.0’s key enabling technologies (KETs) – advanced materials modelling, connected machines, data mining, cyber-physical systems (CPS), big data, Internet of things (IoT), augmented reality (AR), cloud computing, cybersecurity, etc. Obviously, the Digital Twin is the strategic connection between the digital and real worlds, and is geared towards minimizing scrap production (zero defect manufacturing, ZDM) and maximizing overall equipment efficiency (OEE). In this area, EnginSoft’s AI-driven technology supports resource and time usage, maintenance, configuration and automation, as well as quality forecasting. The Circular Economy links raw materials, eco-design, energy-aware processes, and the recycling and reuse of waste at the end of the product’s life.

While the well-recognized Industry 4.0 definition was developed in 2011 to describe the process of digitalization and interconnection in the factory of the future, only a limited percentage of companies have actually implemented the process of Digital Transformation. Similarly well-known is the series of advantages to be had and barriers to be encountered in tackling a 4.0 project.

EnginSoft has been helping its clients to overcome the barriers and to derive the earliest benefits due to its many years of multi-disciplinary experience:

The Smart Factory strategy develops and implements advances in measurement science that enable performance, quality, interoperability, wireless and cybersecurity standards for real-time prognostics and monitoring, control, and optimization of the integrity of smart manufacturing systems.

Smart Factories are complex manufacturing ecosystems in which the convergence of technologies and operational and ICT skills drive digital transformation.

Investment growth is estimated at 1,7% in the digital economy, and +40% of in the smart factory over the next 5 years, if the technological potential is unleashed through appropriate governance, transversal skills and a data-driven culture.

In 2024, the value of the smart factory could reach 1.4 trillion euros as a result of increasing productivity, extending market share, and improving quality and customer experience. However, , this will only be achievable if a strong governance program and a culture of data-driven operations are implemented.

The market for intelligent production platforms alone reached € 4 billion in 2019 and is expected to grow steadily over the next five years. According to the latest research, China, Germany and Japan are the top three countries in terms of smart factory adoption, closely followed by South Korea, the US nd France.

Two challenges are emerging: the convergence of IT and operating technology systems, and the expansion of the range of skills and capabilities needed to drive transformation, including cross-functional skills, transversal or soft skills, and digital talent.

Any EU manufacturing company needs to strive for excellence and competitiveness by improving productivity, quality management and time-to-market in accordance with global priorities corresponding to macro-challenges and impacts.

The innovative, high-tech product is the market’s answer to compliance with societal requirements and innovation along the product life-cycle. Manufacturing teams must be prepared to manage the new machine- and data-driven production controls reshaping human-machine interaction and decision making, while taking into account energy and resource efficiency. The final and most important impact will be the footprint for the planet.

Reducing manufacturing industry emissions is a must and can be achieved through waste reduction, recycling, renewable energy and resource efficiency.

The 2018 World Manufacturing Forum Global Report identifies six areas of manufacturing that will shape its future development (cognitive, hyper-personalized, risk-resilient, circular, inclusive and rapidly-responsive).

Six disruptive trends for the future of manufacturing

(source: World Manufacturing Forum, www.worldmanufacturingforum.org)

EnginSoft is investing in some of the six disruptive trends for the future of manufacturing by introducing a digital approach for each of them.

The digital approach supported by EnginSoft is a fundamental element of inclusive and resilient manufacturing.

The 2020-2027 key priorities require innovative solutions that integrate the well-established key enabling technologies (KETs) of Industry 4.0.

EnginSoft, with the collaboration of strategic partners, is well-positioned to make a highly relevant contribution to the KETs that coordinate the integrated multi-disciplinary 4.0 project.

The robust product design, the simulation of manufacturing process and the digital quality approach proposed by EnginSoft is oriented to scalable lot-size first-time right manufacturing.

Agile manufacturing means adapting to customer needs in search of maximum flexibility in automation, and plug-and-play production lines supported by virtual commissioning or system engineering modelling. Robust, optimal manufacturing includes new materials or advanced technologies (e.g. additive manufacturing) that are virtually integrated and optimized taking into account the multi-stage production line and supply chain in a unique simulation workflow (the simulation-driven digital twin). In addition, the manufacturing digital twin regulates and predicts the quality and failures in production in sand factories for connected machines in real time.

The digital twin solution integrates end-to-end life-cycle engineering from product to production lines at different levels.

Innovative design is supported by CAE product performance verification, assembly and in-service capabilities with a model-based definition approach (e.g. chain of tolerance impact) and AI-driven solutions. Product-associated services (e.g. predictive maintenance of machines or lifespan prediction in a massive production) are designed with simultaneous, holistic and collaborative product-service engineering. The more complex and intelligent the product, the more important is the integrated process-to-product design chain (e.g. design for additive manufacturing).

The innovative product responds to demand and consumer-oriented manufacturing networks with the estimation of the product footprint.

More and more design scenarios are proposed by the simulation-driven digital twin. The Pareto set of feasible solutions includes advanced materials, different configurations and manufacturing processes in a multi-objective workflow to overcome the contrasting objectives of mechanical performance and durability with the metrics of eco-sustainability, cost and resource-efficiency.

The traditional computer-aided technologies (CAx) and virtual tools or the complex digital twin are tools for people. Human beings are always the leaders of innovation, using digital tools supported by data analytics and decision support systems (DSS) (e.g. the data-driven digital twin).

The graphical user interface (GUI) is fundamental because human and digital technologies are complementary (e.g. the way human skills complement A.I. solutions) like a Cobot in robotics. The digital solution must involve all stakeholders in the factory and along the value chain to support decision making to manage constant change.

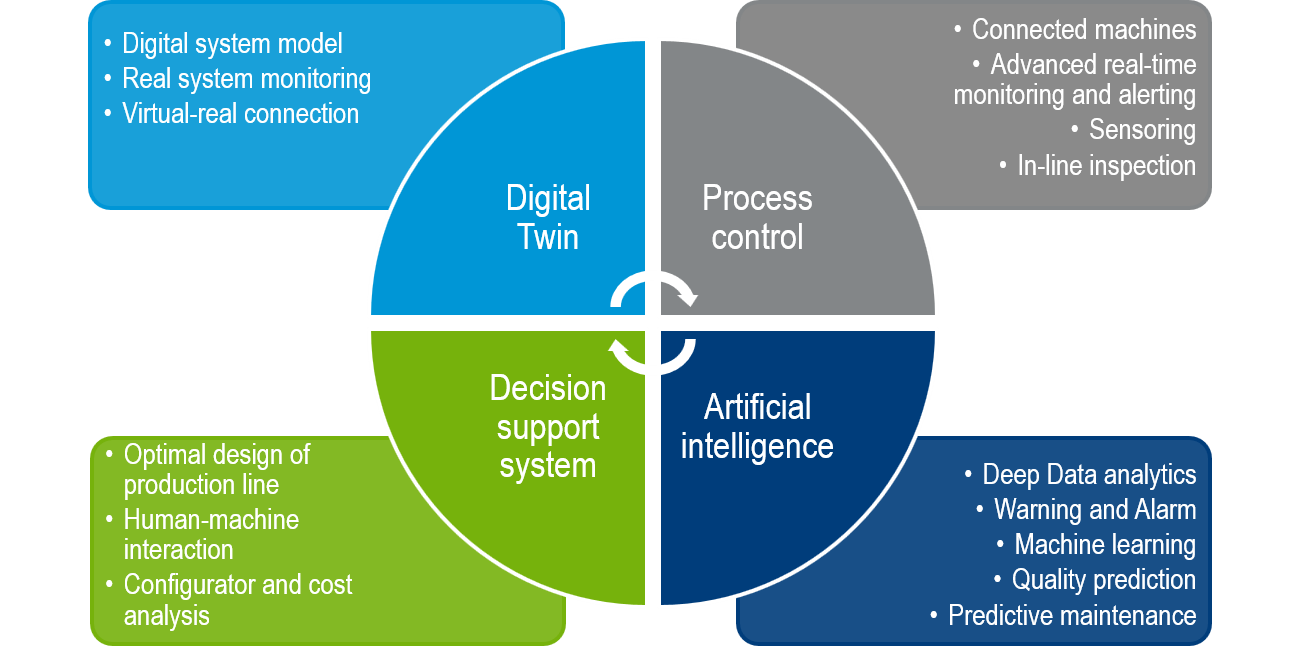

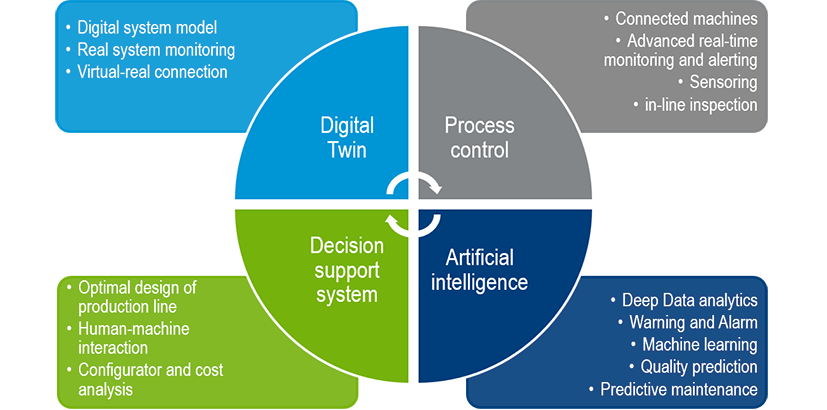

There are four new key enabling technologies (KETs) for future Smart Manufacturing: the digital twin (DT), intelligent process control (IPC), artificial intelligence (AI), and decision support systems (DSS)

Definition of the Digital Twin

A Digital Twin is a virtual and connected model of a real working system. The DT consists of three elements: intelligent process control (IPC), AI-driven modelling, and Decision Support Systems (DSS). It reproduces the behavior and history of the real system, allowing better resource management.

Intelligent Process Control (IPC)

If the DT is not classified as a single virtual model separated from real performance, it is ranked above other new KETs such as Intelligent Process Control. Machine-to-machine (M2M) connectivity and new sensors/alerts advance the collection of input data from the production system to be correlated with in-line inspection measurements in a comprehensive tracking framework referred to as Product ID or Cycle.

Artificial Intelligence (AI)

The application of deep data analytics (DDA) and machine learning (ML), already applied in other fields, interprets the complex and highly non-linear correlations between data to understand, predict and optimize the performance of a process, product or service. The first result is the automatic definition of alarm and warning thresholds; the final goal is the predictive model of product quality or the prediction of equipment failure to improve maintenance (e.g. maintenance as a service, MaaS). The training and re-training of predictive models often requires large amounts of data and the actual dataset could be very expensive in terms of time and resources. EnginSoft proposes the fusion of the virtual and real Design of Experiments (DoE) to accelerate the construction of suitable data set.

Decision Support System (DSS)

If data is the newest asset of smart manufacturing, data interpretation and visualization must be intelligent and fast to support decision making in case of performance deviations. The optimal new configuration of production parameters is based on a deeper cause-effect correlation to react quickly and correctly.

CASE STUDY

This paper explores the transformative potential of Extended Reality (XR)—encompassing Virtual Reality (VR), Augmented Reality (AR), and Mixed Reality (MR)—when integrated with Artificial Intelligence (AI) in industrial and engineering applications. XR technologies enable businesses to visualize, interact, and optimize product designs, training processes, and customer support functions.

digital-manufacturing optimization artificial-intelligence

CASE STUDY

In this case study, EnginSoft engineers explain how they used modeFRONTIER to assist Comau, a Fiat Chrysler subsidiary, to optimize their approach to the preliminary design of production systems for automotive manufacturing system RFQs.

automotive optimization rail-transport modefrontier SIMUL8 iphysics industry4

CASE STUDY

A collaborative project between Nissan Technical Centre Europe, RBF Morph, and the University of Rome “Tor Vergata” showcases how multi-physics optimization is revolutionizing automotive wheel design, particularly for electric vehicles (EVs). By integrating styling, structural analysis, and aerodynamics within a unified workflow enabled by advanced mesh morphing technology (rbfCAE), designers can optimize wheels for lightweight, strength, and aerodynamic efficiency without compromising aesthetics.

automotive optimization

Some software solutions for Industry 4.0 - Strategy and Research

software

Maple Flow is an advanced software for symbolic processing, visualization, and analysis of mathematical data and models. Developed by Maplesoft, Maple Flow combines the power of symbolic computation with an intuitive interface, allowing users to explore and solve complex problems efficiently.

maple maplesim

software

industrialPhysics is an innovative simulation platform for the digital design and virtual commissioning of complex production machines, lines and plants.

iphysics industry4 optimization mechanics

software

Maple is an advanced numeric and symbolic solution with a powerful maths engine. Maple is used by Design Engineers and Advanced Analysts to quickly and accurately perform calculations and mathematical manipulations using live mathematical expressions.

maple maplesim