Particleworks

Une solution logicielle CFD avancée, basée sur la méthode de simulation de particules en mouvement (MPS)

Particleworks est un produit de Prometech.

Particleworks est un produit de Prometech.

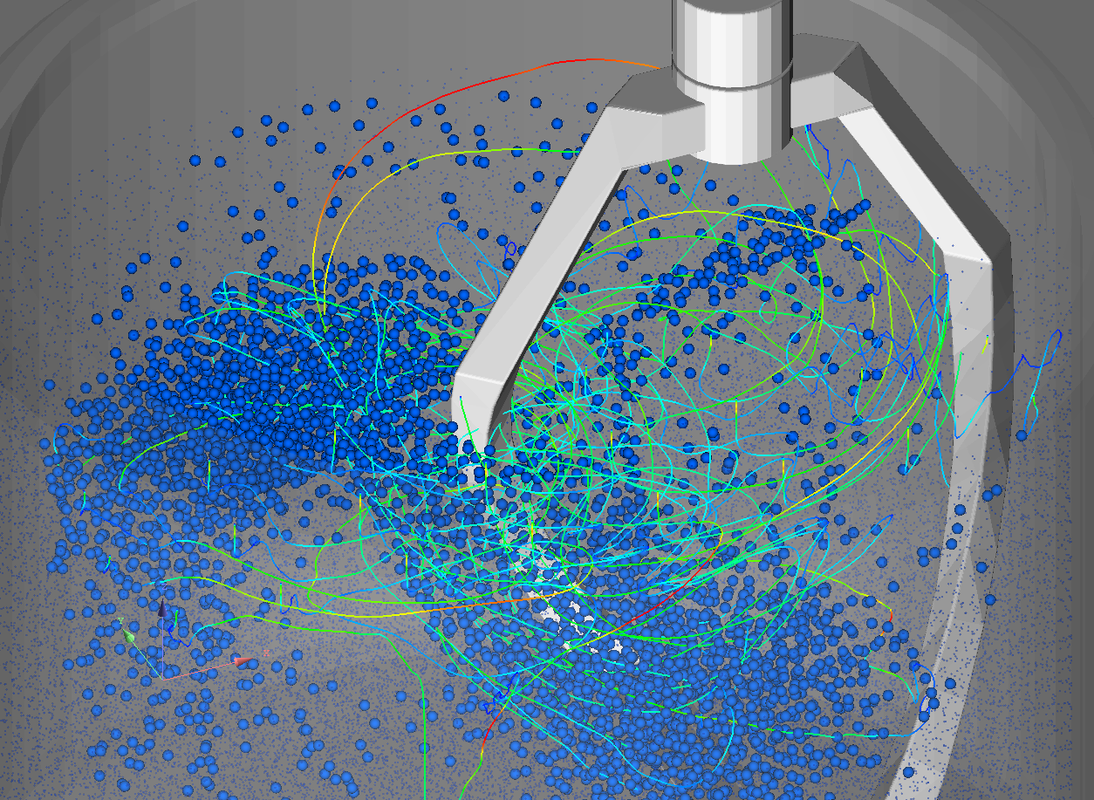

Particleworks est une solution logicielle CFD avancée, basée sur la méthode de simulation de particules en mouvement (MPS).

Distribué par EnginSoft dans toute l’Europe, Particleworks permet de réaliser d’importantes économies de temps et d’argent sans générer de maillage comme les logiciels CFD conventionnels.

Avec Particleworks, les ingénieurs sont en mesure de modéliser et de simuler des problèmes à grande échelle sans nécessité de ressources matérielles importantes.

Pour les utilisateurs de CFD, Particleworks peut vous aider à obtenir un processus plus rapide et plus efficace en consommant moins de ressources matérielles.

Pour les ingénieurs préférant les tests physiques, car la CFD traditionnelle prend trop de temps, complexe et demande trop de ressources, Particleworks peut les aider à économiser de l'argent grâce à la simulation sans maillage.

brochure

Moving Particle Simulation (MPS) is a meshless method of Computational Fluid Dynamics (CFD) specifically conceived to analyse liquid flows, from the most common liquids like water and oil, to the most complex ones such as highly viscous consumer products, adhesives, polymers, and foods or even semi-solid materials like grease or organic waste.

This publication is a collection of papers addressing different industrial sectors and covering applications ranging from lubrication of transmissions, cooling of engines, prevention of aquaplaning, and fire extinguishing, to the electrification of mobility solutions and the study of snow drifts.

Particleworks

Envoyez vos questions techniques à nos experts !

Mettez-vous en relation avec un expert EnginSoft qui pourra vous apporter une réponse fiable à votre question technique ou vous recommander une solution éprouvée.

CASE STUDY

Transmission design is mainly based on the mechanical aspects of the transmission and lubrication is an aspect that is verified, and eventually corrected, based on bench testing, i.e. once the design phase has been completed and a physical prototype is available.

mechanics particleworks automotive

CASE STUDY

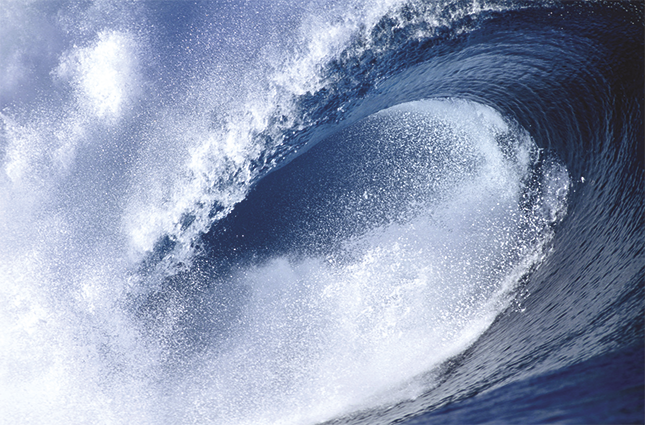

In this technical article, we demonstrate how to apply a one-way coupling technique using a combination of ParticleWorks and LS-DYNA to estimate tsunami damage to a vehicle.

automotive ls-dyna energy cfd particleworks environmental

CASE STUDY

In this article, Uteco describes how it applied Computational Fluid Dynamics (CFD) to assist the design and improvement of its printing machines.

cfd ansys mechanics

CASE STUDY

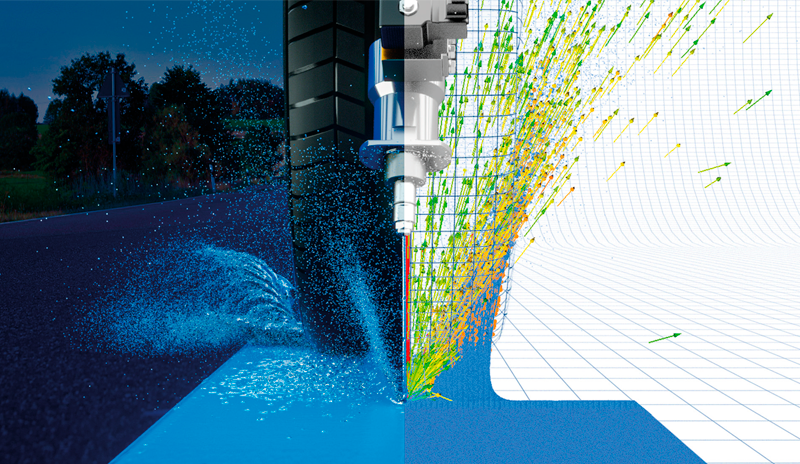

In this paper, we discuss the digital modelling and simulation of the EASYRAIN Aquaplaning Intelligent Solution (AIS) using mesh-free moving particle simulation (MPS).

automotive particleworks

CASE STUDY

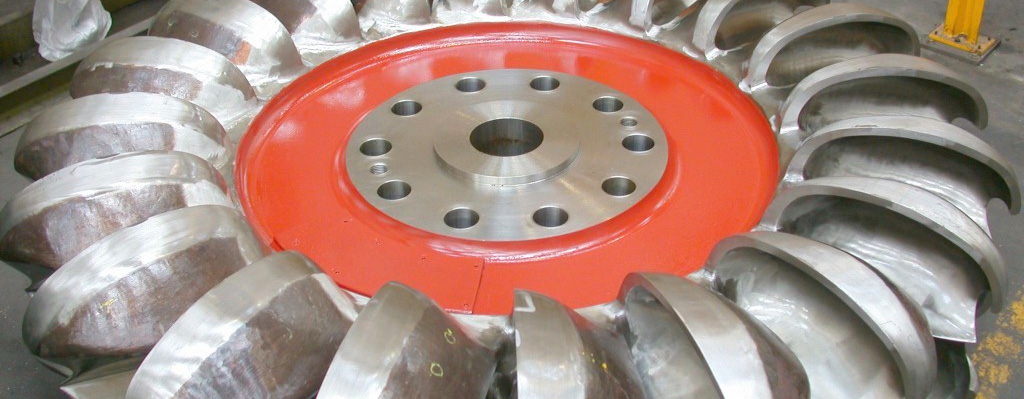

EnginSoft developed a Computational Fluid Dynamic (CFD) analysis methodology for the performance evaluation of a Pelton turbine

energy cfd ansys oil-gas