This paper presents the preliminary simulation study of a typical centrifuge currently produced by Gamma Meccanica. The objective of this study is to evaluate the behaviour of the centrifuge using moving particle simulation and discrete element method (MPS-DEM) simulation techniques with Particleworks 7.2.1 to gain a better understanding of phenomena that are impossible to monitor experimentally.

Qualitative and quantitative results, such as the distribution of water and plastic particles within the centrifuge, will be compared to identify key factors for further analysis and improvement in future studies. Particular phenomena like blade erosion due to particle impact will be used for qualitative validation of the model. The presented model and results formed part of a feasibility analysis of different rotor configurations. The varying distribution of the water and particles enabled observations about the performance of different rotor geometries in terms of energy efficiency and moisture in the final product. The results of the numerical comparison will be very useful for future improvements not presented in this article.

Read the articlesoftware

Particleworks is an advanced CFD Software solution, based on the Moving Particle Simulation (MPS) method.

particleworks

CASE STUDY

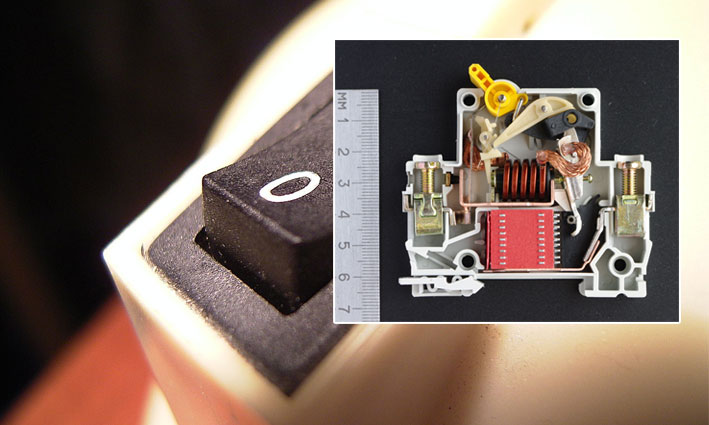

The premium software RecurDyn was used to simulate a Double Pole Single Throw Switch using three different modeling schemes. A comparison of the results provided useful information for the designers.

recurdyn mechanics multibody