Particleworks

Soluzione CFD basata su un metodo numerico avanzato, noto come "MPS - Moving Particle Simulation method"

Particleworks è un prodotto Prometech

Particleworks è un prodotto Prometech

Particleworks è un software CFD basato su un metodo numerico avanzato, noto come "MPS | Moving Particle Simulation method".

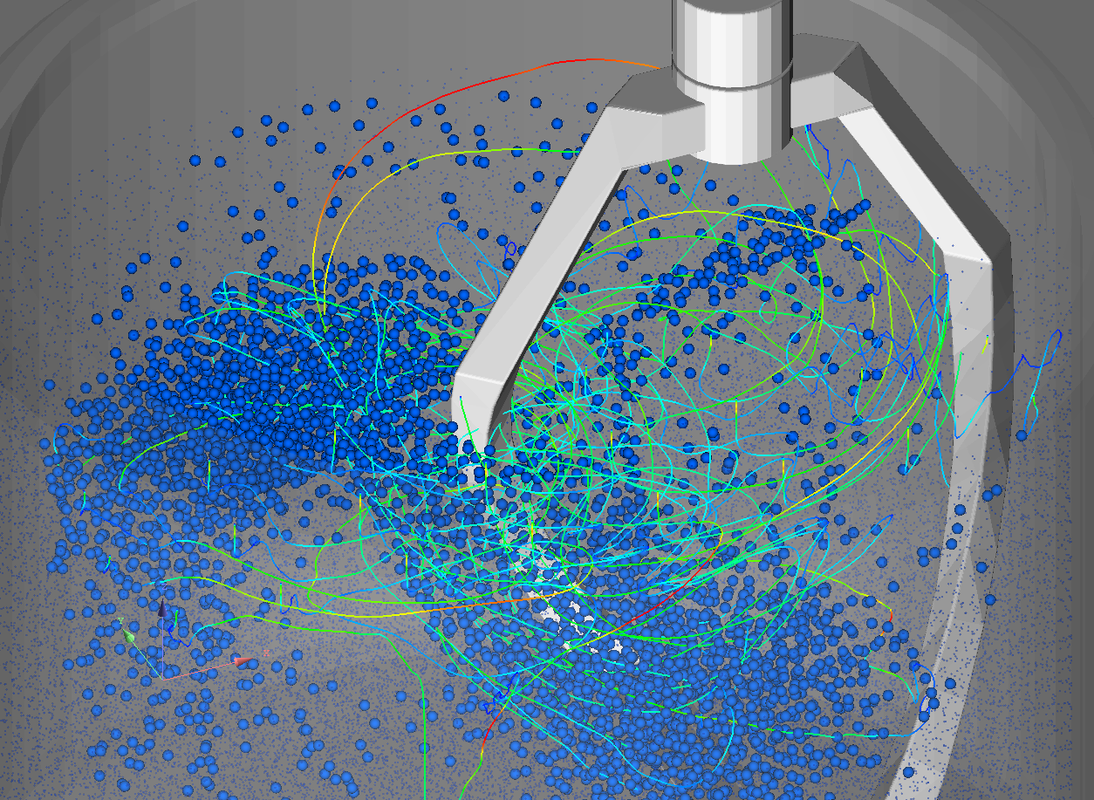

La natura senza mesh di MPS consente una simulazione robusta dei flussi a superficie libera ad alte risoluzioni, risparmiando il tempo necessario per generare mesh per il dominio del fluido.

Particleworks fornisce l'importazione diretta di file dal software CAD per ridurre i costi associati alla generazione di mesh richiesta per il software CFD convenzionale.

Particleworks consente agli ingegneri di modellare e simulare su vasta scala problemi relativi a flussi di superficie liberi, che interagiscono, ad esempio, con i cosiddetti fluidi-rigidi o fluidi-polvere, e che hanno geometrie di contorno complesse.

brochure

Moving Particle Simulation (MPS) is a meshless method of Computational Fluid Dynamics (CFD) specifically conceived to analyse liquid flows, from the most common liquids like water and oil, to the most complex ones such as highly viscous consumer products, adhesives, polymers, and foods or even semi-solid materials like grease or organic waste.

This publication is a collection of papers addressing different industrial sectors and covering applications ranging from lubrication of transmissions, cooling of engines, prevention of aquaplaning, and fire extinguishing, to the electrification of mobility solutions and the study of snow drifts.

Particleworks

Invia le tue domande ai nostri tecnici specializzati!

Mettiti in contatto con uno dei nostri esperti, che ti potrà fornire risposte certe o consigliare soluzioni affidabili.

CASE STUDY

LIXIL is trying to introduce Particleworks, a meshless multiparticle simulation (MPS) computational fluid dynamics (CFD) tool in the research and development of these products.

recurdyn particleworks appliances

CASE STUDY

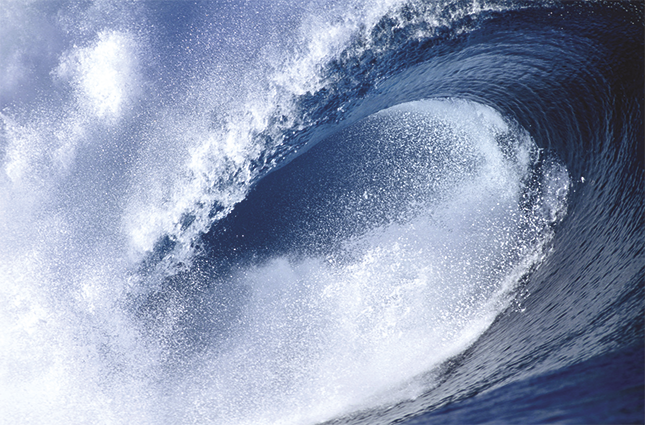

In this technical article, we demonstrate how to apply a one-way coupling technique using a combination of ParticleWorks and LS-DYNA to estimate tsunami damage to a vehicle.

automotive ls-dyna energy cfd particleworks environmental

CASE STUDY

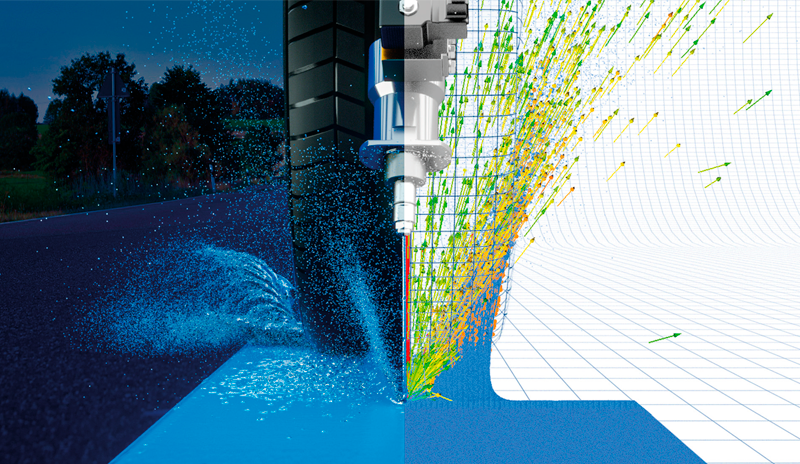

In this paper, we discuss the digital modelling and simulation of the EASYRAIN Aquaplaning Intelligent Solution (AIS) using mesh-free moving particle simulation (MPS).

automotive particleworks

CASE STUDY

This article presents the simulation of rainfall on the outdoor unit of an air conditioner as a concrete example of this approach.

appliances particleworks

CASE STUDY

This technical article, a collaboration between EnginSoft and ZECO, compares two different methodologies for the study and optimization of impulse turbines, specifically Pelton turbines, in order to evaluate which is the quicker and more reliable method.

cfd particleworks energy