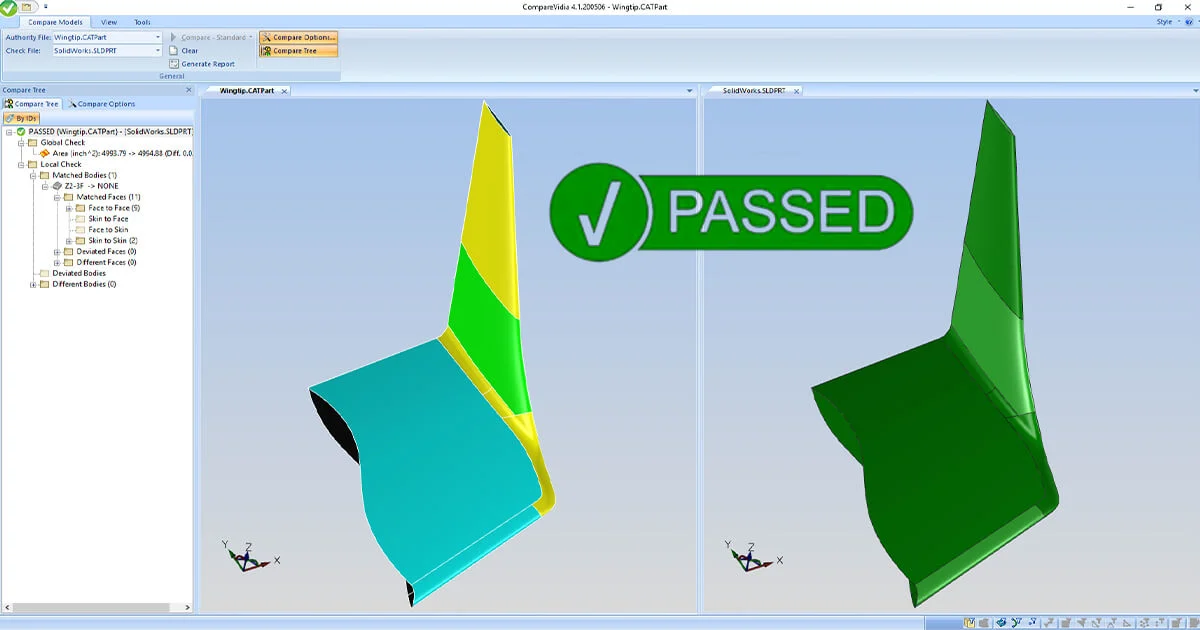

CompareVidia

Derivative CAD Validation & Revision Comparison

CompareVidia ist ein Produkt der Capvidia.

CompareVidia ist ein Produkt der Capvidia.

CompareVidia ist eine einfach zu bedienende Anwendung zum Validieren und Vergleichen von CAD-Modellen. Ein einfacher Arbeitsablauf ermöglicht es Ihnen, zwei CAD-Modelle zu laden und sie anhand Ihrer Kriterien zu vergleichen. Die Modelle werden entweder als BESTANDEN oder als NICHT BESTANDEN eingestuft. Es wird automatisch ein Bericht erstellt, der die Einhaltung von Standards wie Boeings D6-51991 "Quality Assurance Standard for Digital Product Definition" digital zertifiziert.

CompareVidia ist die bevorzugte Lösung führender Hersteller und bietet eine effiziente, leistungsstarke und automatische Methode zur Validierung der Integrität von CAD-Modellen in verschiedenen Phasen des digitalen Produktlebenszyklus.

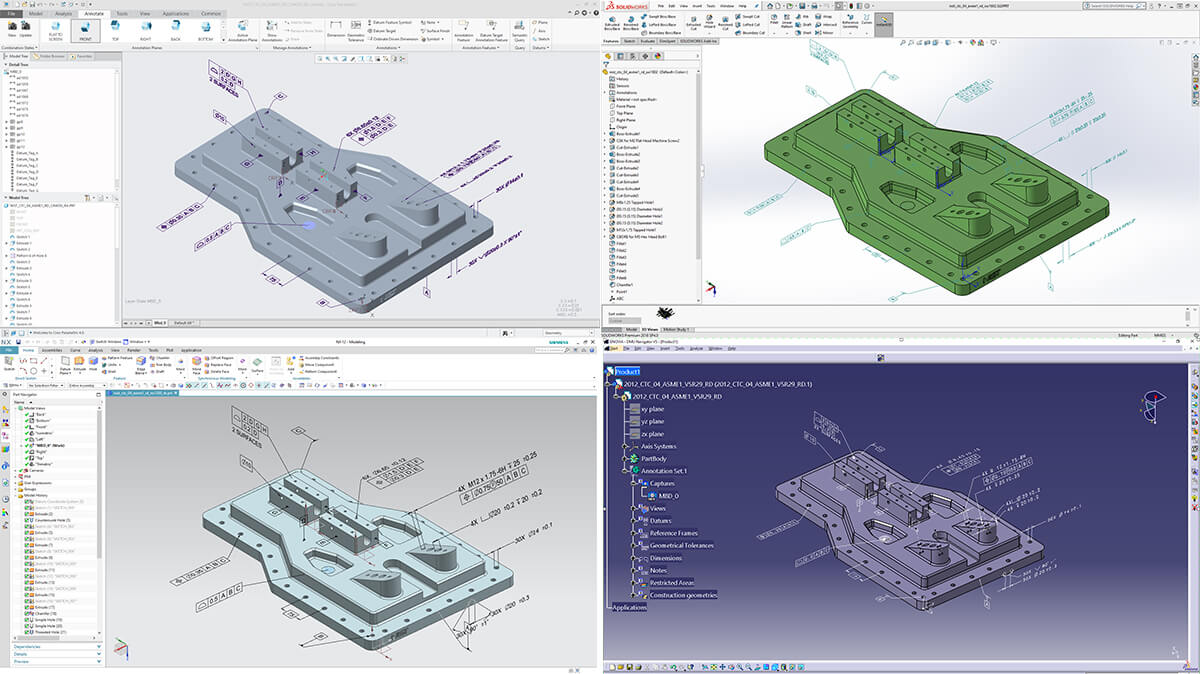

Find out how and why to implement Model-based definition (MBD).

Visit the dedicated section

Stellen Sie unseren Experten jetzt Ihre technischen Fragen!!

Über dieses Formular treten Sie direkt mit einem EnginSoft Experten in Kontakt, der Ihnen eine zuverlässige Antwort auf Ihre Frage geben und eine passende Lösung empfehlen kann.

CASE STUDY

This article examines the simulation of an RCD to determine the factors that affect its response times.

appliances ansys cetol recurdyn tolerances

training courses

The training course on geometric product specification and tolerance analysis addresses the issues related to tolerance management and the approach known as "Dimensional Management", which defines the activities involved and their sequence for achieving the desired quality at the lowest possible cost. We offer a wide range of training courses – scheduled, on-demand and customized – designed to meet the varying needs of individuals and/or the company in which they work: SO-GPS, ASME-GD&T standards, Tolerance analysis and model-based definition, and Software technologies training.

cetol tolerances

CASE STUDY

This article describes how EnginSoft supported Metasystem in acquiring the know-how to satisfy future customer requests on the one hand, and to create projects that are as profitable as possible in terms of waste minimization, on the other hand.

automotive tolerances cetol

CASE STUDY

This article explores the practical implementation of Geometric Dimensioning and Tolerancing (GD&T) according to the ISO GPS standards, focusing on the functional definition and consistent application of Datum Reference Frames (DRFs). DRFs, derived from a component’s functional geometry and assembly sequence, constrain six degrees of freedom to ensure stable alignment and reproducibility during production and assembly.

tolerances mbdvidia comparevidia gdtadvisor cetol

CASE STUDY

This article is the first part of a four-part mini-series exploring key aspects of modern tolerance management in product development. It focuses on Dimensional Management (DM) — a simulation-based engineering methodology essential for ensuring dimensional quality across a product’s lifecycle.

tolerances mbdvidia comparevidia gdtadvisor cetol