MBDVidia

MBDVidia - MBD Workflow & CAD Revision

MBDVidia ist ein Produkt der Capvidia.

MBDVidia ist ein Produkt der Capvidia.

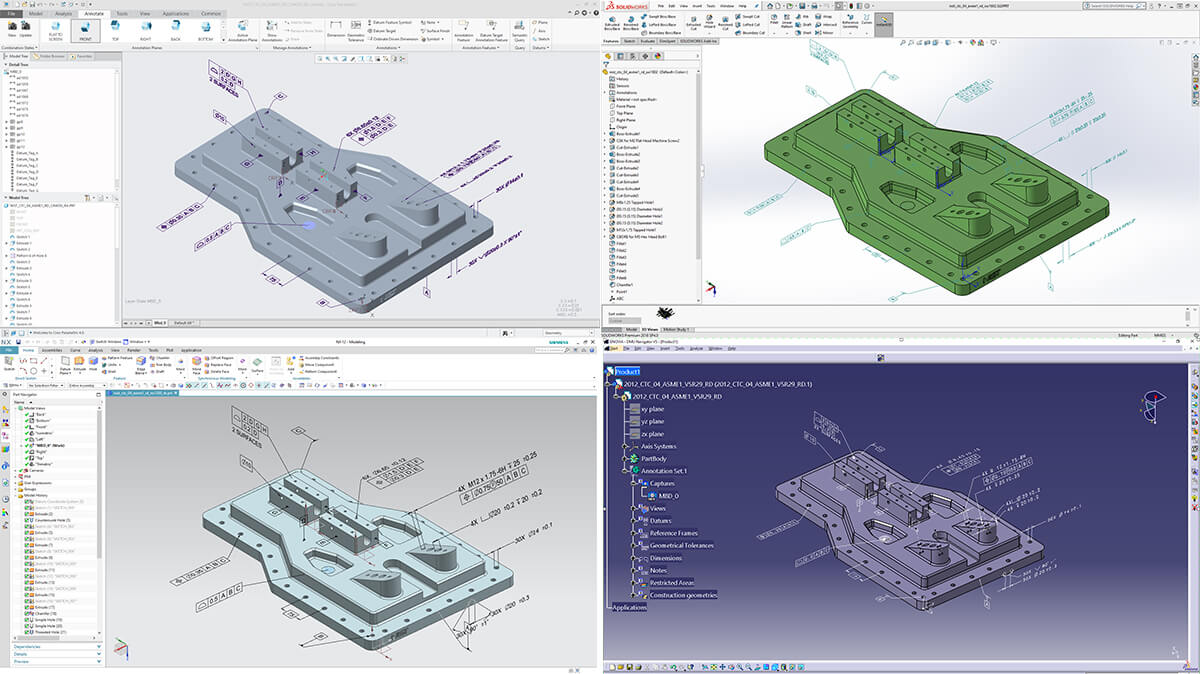

Ihre wertvollen nativen CAD-Daten sind jetzt offen für die Verwendung und Wiederverwendung in jeder Umgebung. Echtes MBD: 3D-CAD + PMI, das für Menschen und Maschinen lesbar ist.

Ihr Autoritäts-Cad-Modell fließt mühelos stromabwärts:

Find out how and why to implement Model-based definition (MBD).

Visit the dedicated section

Stellen Sie unseren Experten jetzt Ihre technischen Fragen!!

Über dieses Formular treten Sie direkt mit einem EnginSoft Experten in Kontakt, der Ihnen eine zuverlässige Antwort auf Ihre Frage geben und eine passende Lösung empfehlen kann.

CASE STUDY

This case study describes ISEO’s project to introduce a global dimensional management approach based on CETOL6σ that starts from the product concept phase and includes design development and prototyping and extends on to cover all other phases of production through to the finished product, with the guidance and support of EnginSoft.

tolerances cetol mechanics

training courses

The training course on geometric product specification and tolerance analysis addresses the issues related to tolerance management and the approach known as "Dimensional Management", which defines the activities involved and their sequence for achieving the desired quality at the lowest possible cost. We offer a wide range of training courses – scheduled, on-demand and customized – designed to meet the varying needs of individuals and/or the company in which they work: SO-GPS, ASME-GD&T standards, Tolerance analysis and model-based definition, and Software technologies training.

cetol tolerances

CASE STUDY

Special Springs commissioned EnginSoft’s engineers to calculate the production cost repercussions of a technical product modification requested by an important customer.

eztol mechanics cetol tolerances

CASE STUDY

Dimensional management in modern manufacturing demands more than just accurate geometric tolerances—it requires data consistency, traceability, and automation across the entire product lifecycle. Traditional practices like annotated PDFs and Excel-based inspection plans introduce risk and inefficiency by detaching product and manufacturing information (PMI) from the 3D model. Siemens’ NX Inspector addresses this challenge through the introduction of Model-Based Characteristics (MBC)—standards-compliant, machine-readable data objects that convert each PMI requirement into a uniquely identified, traceable element within the CAD environment.

mbdvidia tolerances

CASE STUDY

This article is the first part of a four-part mini-series exploring key aspects of modern tolerance management in product development. It focuses on Dimensional Management (DM) — a simulation-based engineering methodology essential for ensuring dimensional quality across a product’s lifecycle.

tolerances mbdvidia comparevidia gdtadvisor cetol