oorja

Plateforme numérique innovante de développement et de modélisation de batteries, qui simule, prédit et optimise leur comportement

Oorja est un produit de oorja

Oorja est un produit de oorja

Deux approches sont traditionnellement utilisées dans la conception d’une batterie.

Avec le premier, le comportement d'une batterie est simulé grâce à l'utilisation de technologies CAE (Computer Aided Engineering), qui permettent de représenter le produit à l'aide de modèles numériques axés sur la modélisation et l'analyse physique. Mais, pour une prédiction précise, il est nécessaire d’introduire une analyse multi-physique, c’est-à-dire d’introduire des paramètres supplémentaires, électrophysiques caractéristiques des batteries par exemple, qui rendent le modèle physique réel plus complexe. À cela, il faut ajouter l'augmentation de la complexité des produits, déterminée par l'émergence de nouvelles technologies et de nouveaux matériaux, et par l'attention portée à la durabilité environnementale. Et c'est cette complexité qui a fait ressortir les limites de l'adoption de cette approche : des temps de calcul croissants, aux compétences étendues requises (sur les logiciels à utiliser, sur les types d'analyses à réaliser, sur les caractéristiques et comportements des nouveaux matériaux, pour ne citer que les principaux).

La seconde approche, plus récente, est plutôt liée aux modèles d’apprentissage automatique (Machine Learning). Dans ce cas, des ensembles de données sont utilisés pour concevoir une nouvelle batterie, composée d’un grand nombre de données collectées expérimentalement.

Mais quelle est la fiabilité de ces données lors de la conception d’un nouveau produit ? La conception et les performances d’une batterie dépendent de nombreux facteurs : la limite dans l’utilisation de cette approche est la disponibilité de données réellement utiles dès les premières phases de conception.

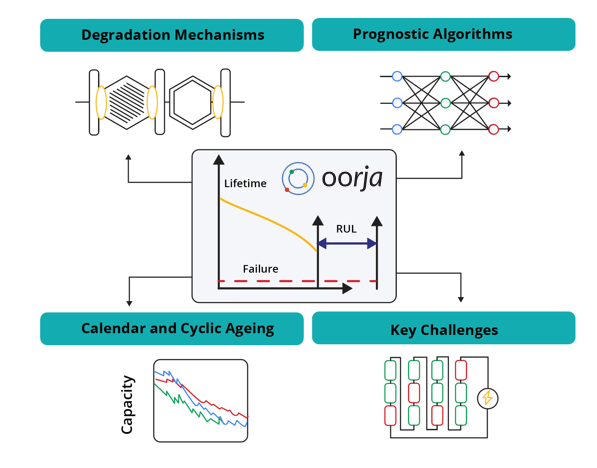

oorja s'inscrit dans ce scénario : la force de cette plateforme réside dans l'adoption d'une approche hybride, qui exploite les avantages des deux méthodologies décrites ci-dessus, et dépasse leurs limites.

oorja utilise une approche basée sur des modèles physiques simples et rapides, qui constitueront la base de l'algorithme d'apprentissage automatique, réduisant ainsi le nombre de données nécessaires pour l'ensemble de données initial.

oorja simule, prédit et optimise le comportement des batteries, en analysant différentes performances, comme par exemple la quantité de courant produite, le « fondu capacité/puissance », la surchauffe pendant l'utilisation, les protocoles de charge rapide et les aspects liés à la garantie.

A la base de la méthodologie il y a un workflow composé de 7 modules :

Pour souligner l'interface graphique extrêmement "user friendly" d'oorja, qui rend extrêmement simple l'utilisation de la méthodologie complexe : elle est basée sur l'utilisation d'un "wizard", c'est-à-dire un système automatique, qui guide l'utilisateur étape par étape dans le workflow génération.

Envoyez vos questions techniques à nos experts !

Mettez-vous en relation avec un expert EnginSoft qui pourra vous apporter une réponse fiable à votre question technique ou vous recommander une solution éprouvée.

CASE STUDY

This technical article describes a comparative study that was undertaken by Intermarine, with the assistance of EnginSoft, between using the Flownex simulation environment and Intermarine’s manual or classic methods (both of which were compared with actual field data from on-board measurements) to predict pressure losses in the various piping systems that convey fluids on board a vessel.

marine energy oil-gas flownex

training courses

Lithium-ion batteries, with their high energy density and long lifespan, are extensively used in a wide range of electronic devices, electric vehicles, and renewable energy storage systems. Explore our range of training courses on oorja, a SaaS platform based on Machine Learning algorithms to analyze and predict the behavior of cells and batteries. By utilizing a limited dataset, it delivers highly accurate and efficient forecasts.

training

CASE STUDY

The car is designed to race on the ultra-flat Salt Flats in Bonneville, Utah. The racecar weighs less than 500kg so increasing the downforce was critical. Reducing aerodynamic drag was also critical due to the power requirements of the racecar.

cfd automotive