PASS

Suite d'analyse et de dimensionnement de canalisations et d'équipements

Start Prof, HYDROSYSTEM, PASS/Equip and Nozzle-FEM sont une suite logicielle de NTP Truboprovod.

Start Prof, HYDROSYSTEM, PASS/Equip and Nozzle-FEM sont une suite logicielle de NTP Truboprovod.

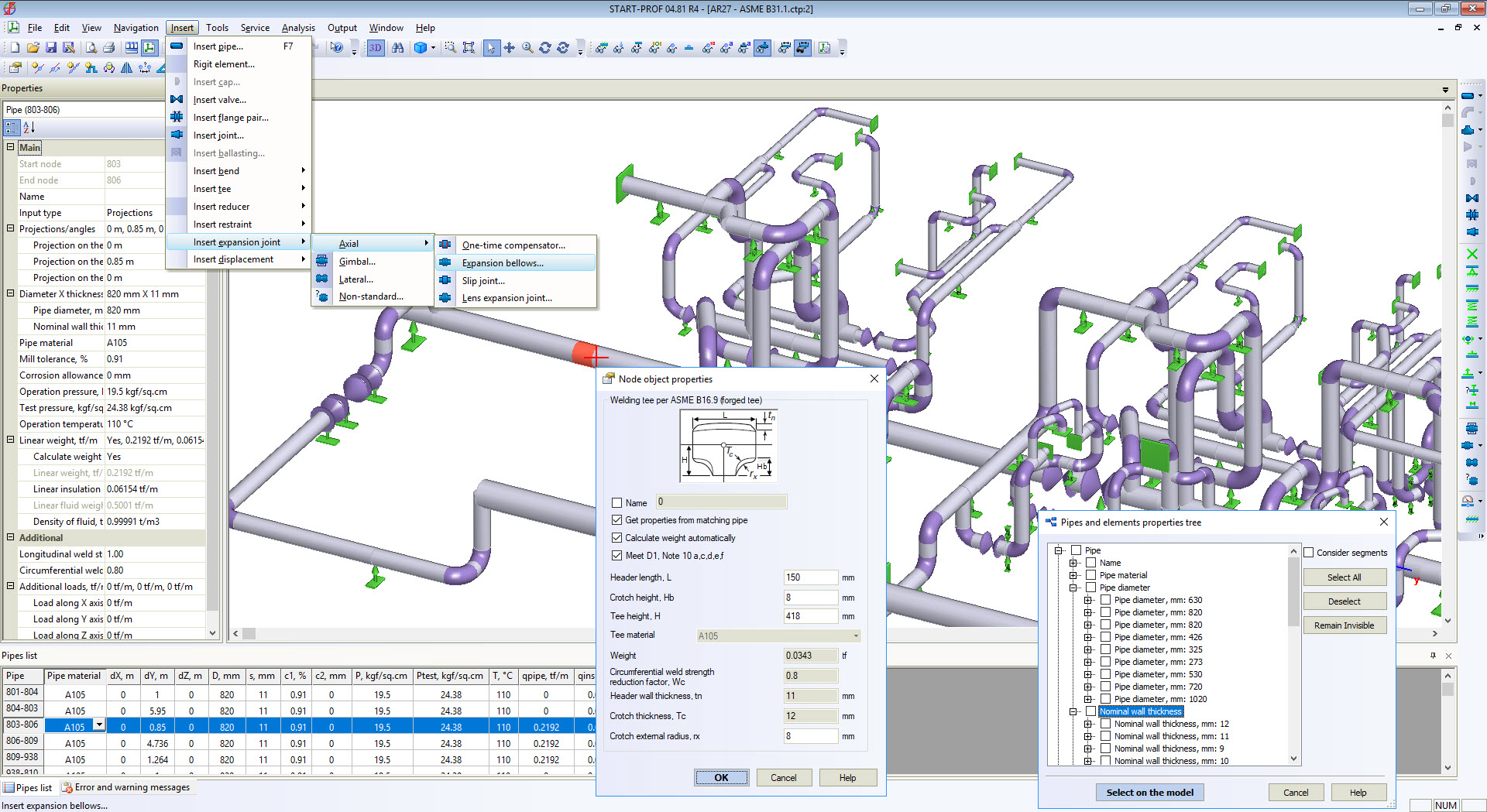

START Prof ® évalue les réponses structurelles et les contraintes des systèmes de canalisations à usage différent sous des charges statiques et cycliques et effectue une analyse sismique. La première édition du logiciel START Prof a été introduite en 1969. Aujourd'hui, START Prof ® est le logiciel d'analyse des contraintes des canalisations le plus utilisé en Russie et dans les pays de l’Europe de l’Est, où il est devenu de facto une référence concernant l’'analyse des contraintes et des flexibilités des oléoducs, gazoducs, et autres canalisations électriques.

Demander une licence d'essai

brochure

Download the "Start Prof: The world’s first Pipe Stress Analysis Software" brochure

NTP Truboprovod

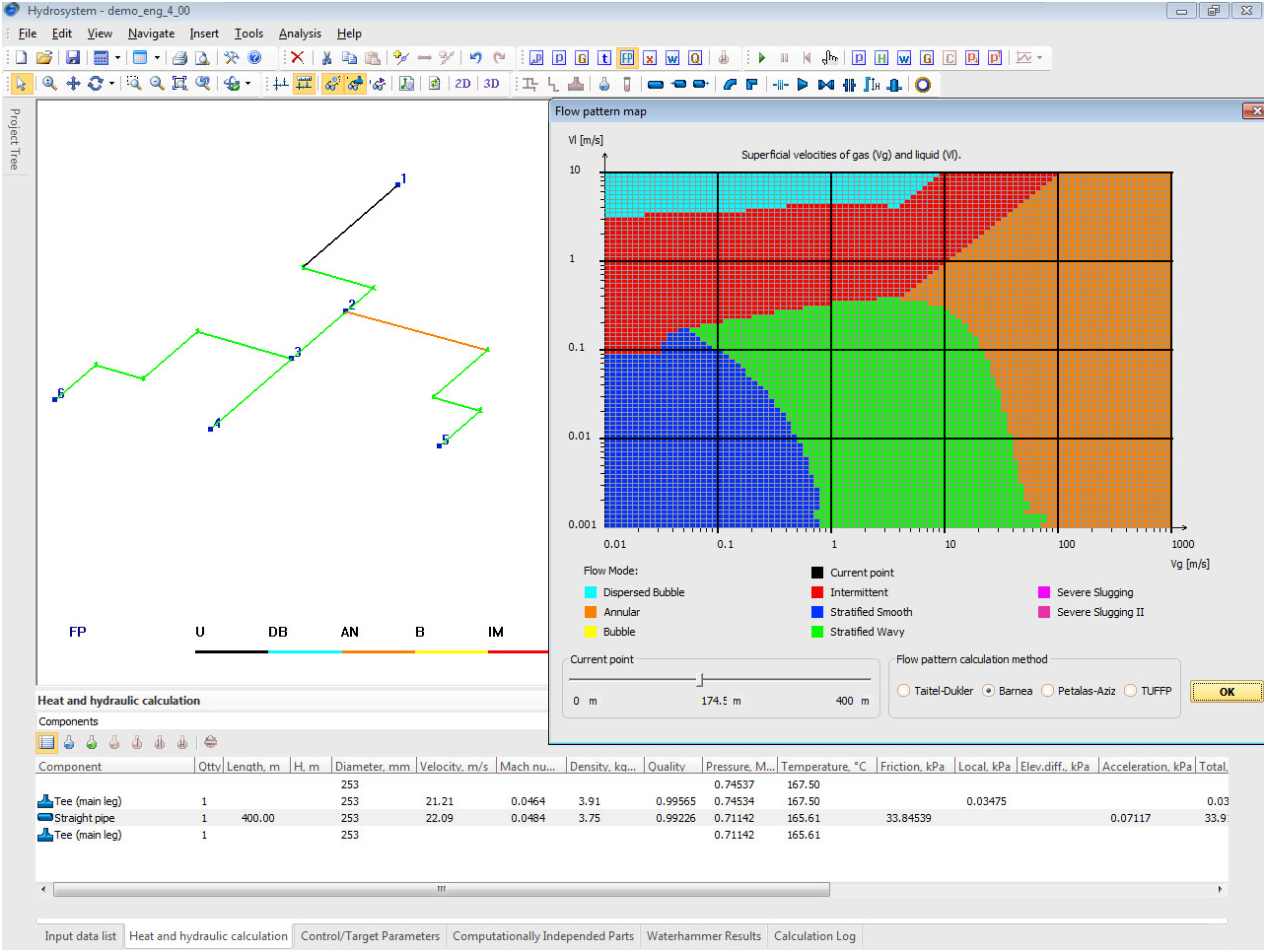

Le logiciel Hydrosystem effectue des calculs de pertes de chaleur et de pertes de charge ainsi que la sélection de la taille nominale des réseaux de canalisations, transportant des fluides monophasiques compressibles ou incompressibles (gaz ou liquides), ainsi que des mélanges gaz-liquides diphasiques. Il est largement utilisé dans les industries de l’énergie, du raffinage du pétrole, de la pétrochimie, du gaz, du pétrole, de la chimie et autres. Différents paramètres de process des canalisations, des conduites principales, des systèmes de chauffage et de distribution de gaz et d'autres réseaux de canalisations peuvent être calculés à l'aide du programme. Hydrosystem permet de calculer des systèmes de canalisations aériennes et souterraines de toute complexité (y compris les réseaux avec boucles). Les résultats de l'analyse peuvent être utilisés pour la sélection des pompes, des compresseurs, des soupapes de régulation et de sécurité afin de garantir la fiabilité et l'efficacité des systèmes de canalisation.

Demander une licence d'essai

brochure

NTP Truboprovod

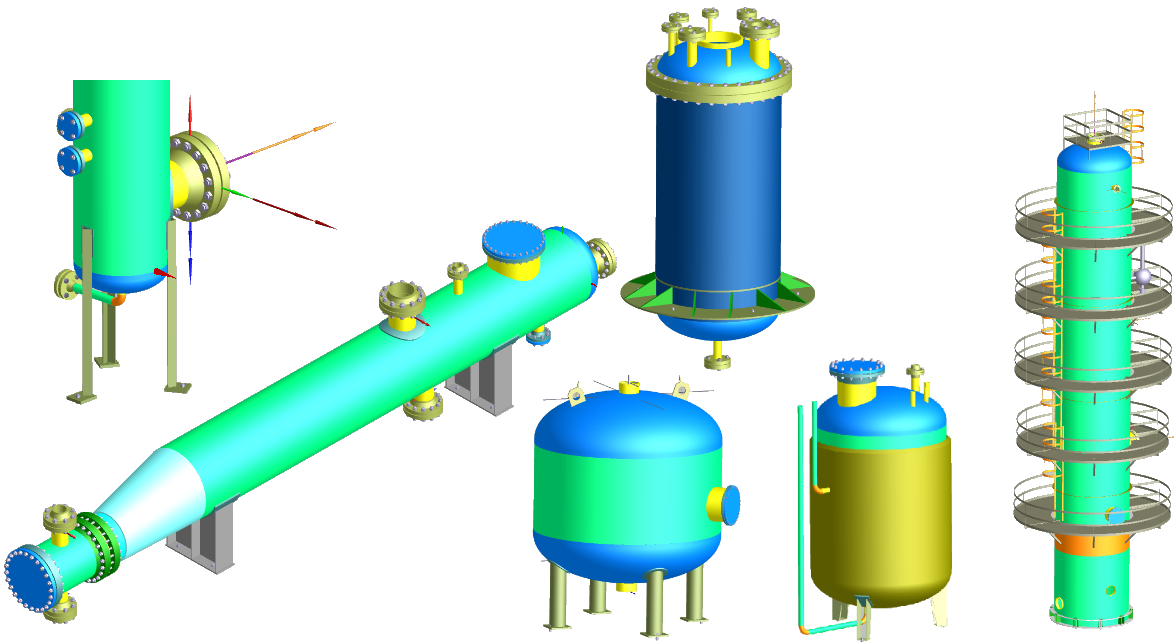

Le programme PASS/Equip est conçu pour le calcul des contraintes et de la stabilité des navires, des appareils et de leurs éléments dans le but d'évaluer leurs capacités de charge dans les conditions de fonctionnement, ainsi que pendant le processus d'assemblage et de tests. Le programme est créé pour la conception, la modernisation et les tests de navires et d'appareils, ainsi que pour effectuer des calculs de contrôle dans les industries de raffinage du pétrole, de la chimie, de la pétrochimie, du gaz naturel, du pétrole et d'autres industries connexes. Le module de base PASS/Equip calcule la contrainte et la stabilité des navires et appareils horizontaux et verticaux conformément aux documents normatifs russes et à l'ASME VIII Div. 1 code.

Demander une licence d'essai

brochure

NTP Truboprovod

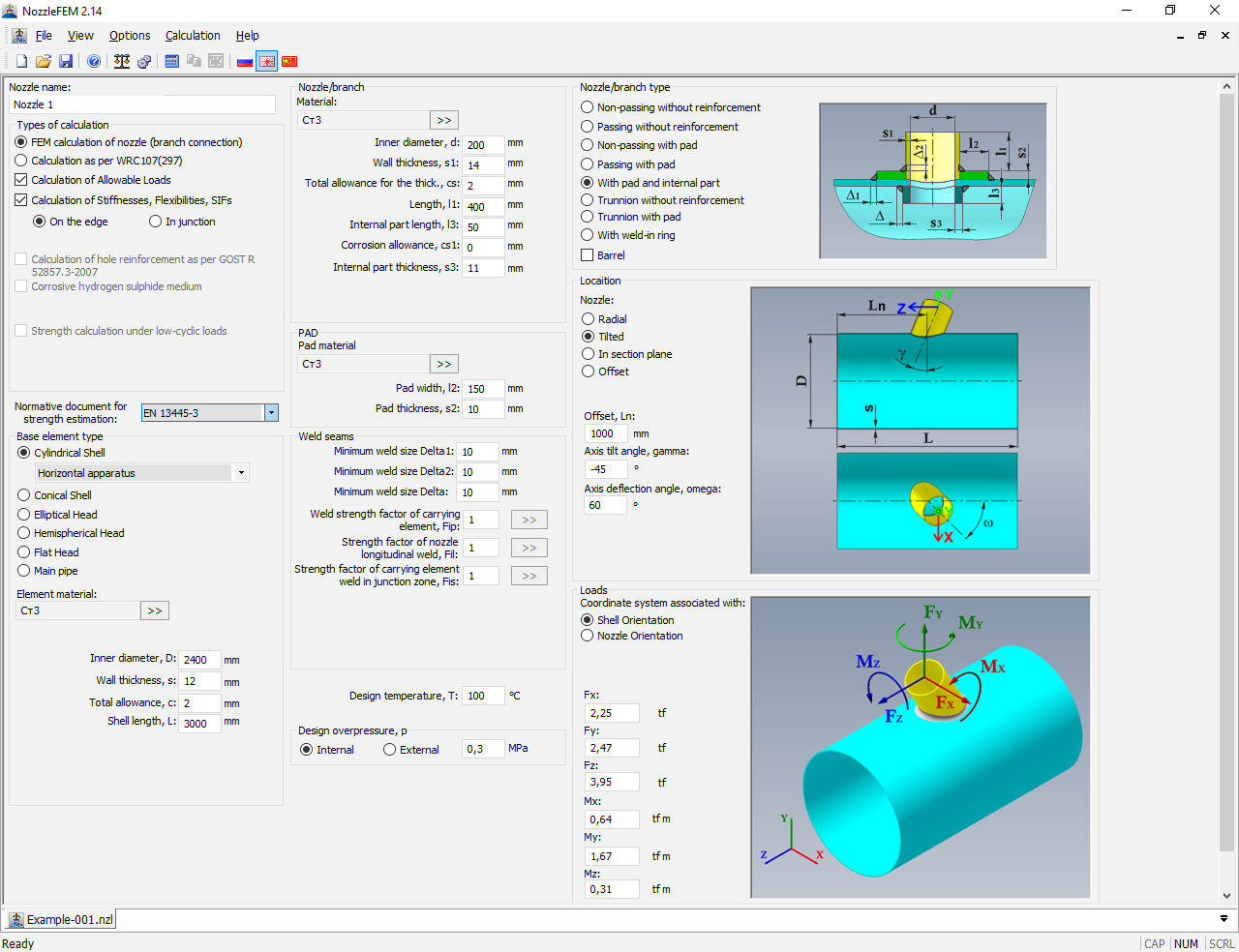

Buse-FEM est conçu pour le calcul des contraintes et de la flexibilité des jonctions buse-coque à l'aide de la méthode des éléments finis (FEM). Le programme calcule également les charges admissibles de la buse et estime la résistance des jonctions de la buse pour une large gamme de configurations géométriques et de conditions de fonctionnement. Nozzle-FEM contribue à fournir un niveau plus élevé de sécurité de l'équipement tout en réduisant les coûts de main-d'œuvre au stade de la conception. Le programme est recommandé pour la conception et l'examen de la sécurité industrielle des installations pétrolières et gazières, de raffinage, pétrochimiques, chimiques, électriques et autres installations industrielles. Contrairement aux programmes FEM universels (ANSYS, NASTRAN, COSMOS, etc.), ce programme ne nécessite pas de formation particulière et peut être utilisé par tout ingénieur en mécanique.

Demander une licence d'essai

brochure

NTP Truboprovod

technical paper

PASS/EQUIP combines sophisticated calculation capabilities and code compliance with ease-of-use to deliver simulation of pressure vessels for strength and stability by even entry-level engineers and designers. PASS/EQUIP provides pressure vessel strength and stability analysis for horizontal and vertical vessels, columns, storage tanks, as well as shell-and-tube and air cooled heat exchangers under static and seismic loads in order to evaluate bearing strength in operation, test, and assembly states.

NTP Truboprovod

technical paper

PASS/HYDROSYSTEM provides diameter selection, heat and hydraulic analysis of steady state flow in piping systems of any complexity, including networks with loops. It also covers the most dangerous type of transitional flow related to liquid surge (water hammer). PASS/HYDROSYSTEM combines sophisticated calculation capabilities with ease-of-use to deliver fluid flow and heat transfer simulation and sizing of any piping network for any design stage by even entry-level engineers and designers.

NTP Truboprovod

technical paper

PASS/START-PROF provides comprehensive stress, flexibility, stability, and fatigue strength analysis with related sizing calculations for buried and above ground, HDPE, FRP/GRP/GRE, vacuum, high pressure, high temperature, and cryogenic piping systems. Calculations are performed under thermal, weight, pressure, wind, snow, ice, seismic, support settlement loads according to the most commonly used standards.

NTP Truboprovod

technical paper

The project scope included steam generation systems design and analysis for the Noor Energy1, 950MW hybrid solar power project in Dubai, the today world largest CSP plant, able to produce electrical power 24/7.

NTP Truboprovod

technical paper

The project included calculation and manufacture of vertical vessels of the VEE or VEP type (GOST 9931-85) (20 units). All vessels are of the same type, but of different sizes.

NTP Truboprovod

technical paper

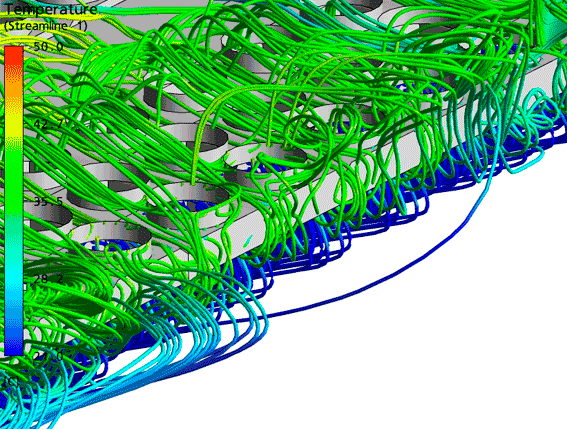

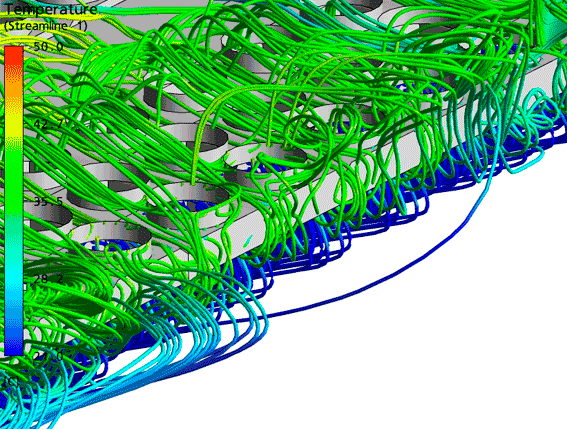

The reconstruction project includes the expansion, transformation and optimization of the original heat supply network main station, the addition of 2 sets of 50 MW Condensing and back pressure turbine generator units, 2 sets of demisting mechanical cooling towers (6 groups), cooling water system and the related ancillary equipment, etc.

NTP Truboprovod

Envoyez vos questions techniques à nos experts !

Mettez-vous en relation avec un expert EnginSoft qui pourra vous apporter une réponse fiable à votre question technique ou vous recommander une solution éprouvée.

CASE STUDY

EnginSoft developed a 3D CFD model of a Liquefied Natural Gas (LNG) Plant for the simulation of the Air-Cooled Heat Exchanger Systems’ (ACHE) arrays and their interaction with the wind.

energy cfd ansys oil-gas

CASE STUDY

In this technical case study, EnginSoft was called in to assist in the application of Computational Fluid Dynamics (CFD) to model the flame size of a regeneration gas-fired heater for a project in Oman.

ansys mechanics energy oil-gas

CASE STUDY

The cumbersome task of verifying structural design according to numerous standards has always been a challenge. Through tireless dedication and relentless innovation, engineers found that they were able to conduct standards verification directly within Ansys Mechanical, Simcenter 3D, and Femap using SDC Verifier software.

sdc-verifier oil-gas

CASE STUDY

This technical article presents a study to design a device that operates entirely on the principle of trapped vortices that intrinsically improve the mixing of hot combustion gases with fresh mixture, a characteristic that is essential both to diluted combustion and to Moderate or Intense Low-oxygen Dilution (MILD) combustion.

ansys cfd turbomachinery energy oil-gas

CASE STUDY

EnginSoft developed a 3D CFD model of a Liquefied Natural Gas (LNG) Plant for the simulation of the Air-Cooled Heat Exchanger Systems’ (ACHE) arrays and their interaction with the wind.

energy cfd ansys oil-gas