Dynamic response of a buried pipeline, under the action of the fall of rocks on the soil

Safety assessment of a buried pipeline potentially subject to rockfalls

Newsletter EnginSoft Year 13 n°3

By Massimo Tomasi | EnginSoft

Oil or gas pipelines that cover long distances pose complex design challenges. Every environment the pipeline crosses is characterized by different potential geohazards. One of the most dangerous for a pipeline is a rockfall. This specific geological hazard, therefore, requires detailed analysis, particularly for the design of onshore pipelines. The virtual representation of the phenomenon has to be as realistic as possible; it is best approached with Finite Element Analysis which allows engineers to accurately analyse problems with high-speed, highly nonlinear dynamics. This article describes how the engineers simulated different types and impacts of rockfalls to measure their effect on different configurations of the soil and the buried pipeline below it to find the optimal burial depth and composition for the backfill soil to ensure the pipeline’s safety.

Read the articleCASE STUDY

In our two-part feature article, Livio Furlan explains how numerical simulation is used to design and plan structures that will resist the specific environmental characteristics of marine mineral resource extraction, as well as its role in meeting standards and regulatory certification.

oil-gas

CASE STUDY

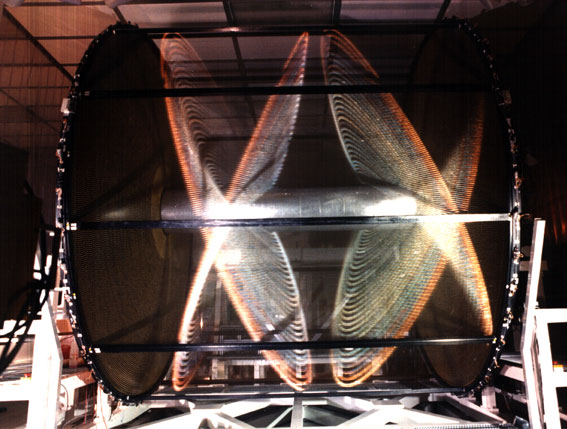

The ultimate goal of the study was to optimize the Drift Chamber’s performance in terms of stiffness, strength and weight o be mounted on the Mu2e particle detector at FermiLAB in Chicago

construction modefrontier ansys optimization energy