CASE STUDY

At this particular moment in time, this article wishes to reflect on the evolution of CAE and simulation in an effort to present a big-picture view when most of us are daily dealing with all the devil in the details in every aspect of our lives. We approached some long-standing business friends in engineering simulation from various regions around the world to help us in this task

ansys industry4 news

CASE STUDY

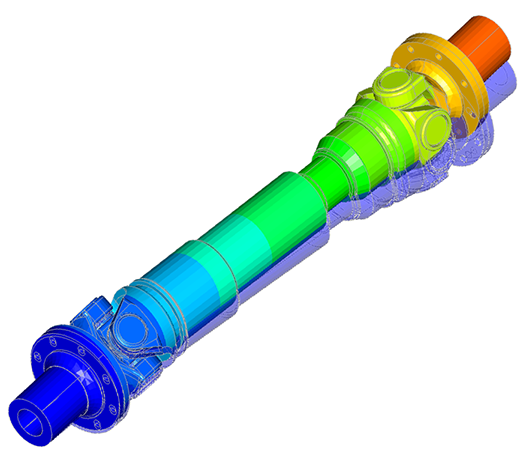

Mesh morphing has proven to be a valuable tool in parametrizing numerical models to perform shape optimization. It allows engineers to save time in generating new configurations for analysis because it does not require geometry modification and mesh re-generation.

ansys mechanics

CASE STUDY

This technical article describes a project undertaken by OPEM to optimize and validate the laws of motion governing the moving operations of a machine that produces coffee capsules, namely the cut and weld unit, the film feeder, the conveyor and the support structure.

consumer-goods multibody recurdyn food-beverage mechanics

CASE STUDY

In this technical article, Fiat Chrysler Automobiles explain how they created a multibody optimization project to identify the optimal values for the powertrain suspension stiffness for a three-cylinder engine in order to minimize the vibrations at idle condition and ensuring greater ride comfort to the passengers.

automotive optimization modefrontier

CASE STUDY

The following article explains how this new approach to the design of automated machines can enable industrial automation OEMs and system integrators to achieve these business imperatives with the assistance of industrialPhysics simulation software.

mechanics iphysics industry4

CASE STUDY

This article explains how the simulation of a severe fire in a warehouse that had caused substantial damage was undertaken. It explores the use of the fire dynamics simulator (FDS) code, developed by the US National Institute of Standards and Technology (NIST)

civil-engineering

CASE STUDY

This article describes the multibody simulation of a switch disconnector and its validation with experimental tests, undertaken by LOVATO Electric for the purpose of conducting a detailed evaluation of a potential new tool to design the mechanical part of its electrical devices.

recurdyn multibody electronics

CASE STUDY

Marelli Motori engineers use Ansys multiphysics solutions to custom-design motors and generators to solve challenges in hydropower, cogeneration, oil and gas, civil and commercial marine transport, military applications, and ATEX applications involving motors and generators in explosive atmospheres, among other applications.

automotive ansys energy

CASE STUDY

In this article, we show that the main turbine characteristics, such as efficiency and exit flow angle, can be sufficiently improved using parametric optimization.

modefrontier energy optimization

CASE STUDY

This technical article describes a comparative study that was undertaken by Intermarine, with the assistance of EnginSoft, between using the Flownex simulation environment and Intermarine’s manual or classic methods (both of which were compared with actual field data from on-board measurements) to predict pressure losses in the various piping systems that convey fluids on board a vessel.

marine energy oil-gas flownex

CASE STUDY

A client wanted to evaluate the dynamic performance of a new-concept forklift, so a fully-functional multibody model of the forklift was built by assembling the client’s CAD geometries.

multibody automotive mechanics recurdyn

CASE STUDY

This technical article describes a new, automated approach to accurately and robustly morph CAD geometry based on results of analysis in order to facilitate the missing bi-directional transfer of these geometries between analysis/test/manufacture and design. Two industrial examples using this approach are also provided, in the morphing of a turbine blade deformation model and aero-elastic deformation of aerodynamic shapes for the NASA Common Research Model.

aerospace