Taking stock: the evolution of simulation around the world pre- and post-Covid-19

From its earliest days through to future post-pandemic perspectives

Newsletter EnginSoft Year 18 n°1

By Kathleen Grant and Marisa Zanotti | EnginSoft

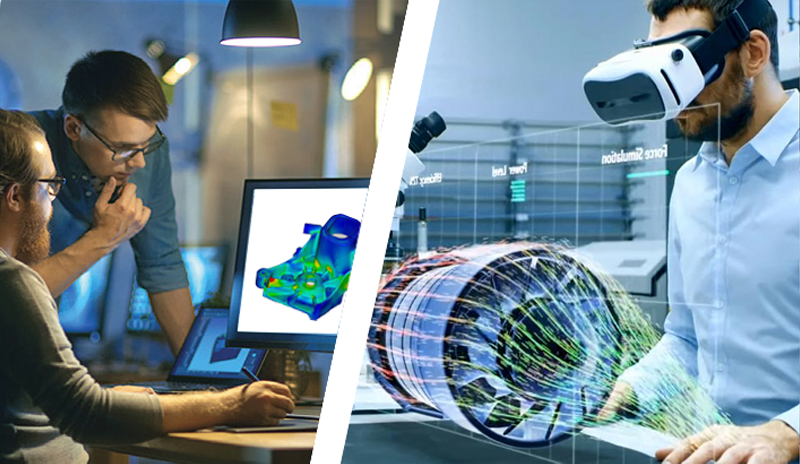

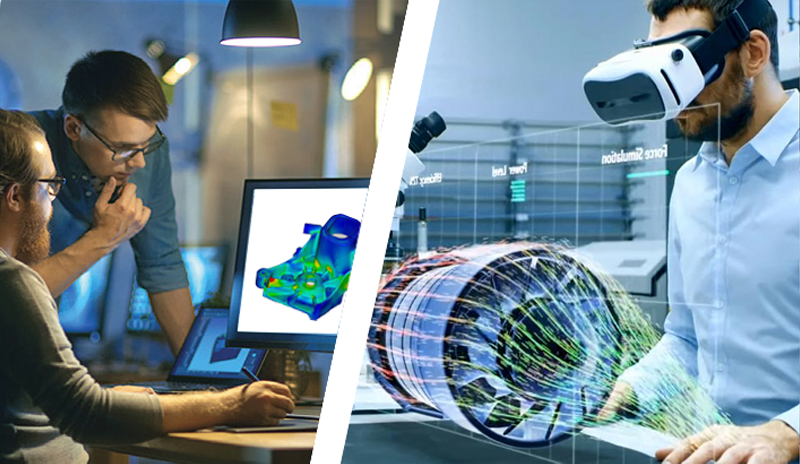

At this particular moment in time, this article wishes to reflect on the evolution of CAE and simulation in an effort to present a big-picture view when most of us are daily dealing with all the devil in the details in every aspect of our lives. We approached some long-standing business friends in engineering simulation from various regions around the world to help us in this task.

The contributors come from different countries in Europe, the USA, Brazil, and Korea. Each had as different an early beginning as can be imagined considering the differences geographically, economically, technologically, and culturally. They all began their careers in technical roles as users of finite element simulation, after which their careers developed into management positions in various technical and consulting capacities that saw them involved in the deployment and application of the different generations of these advanced technologies over a period of thirty years.

This, therefore, provides an interesting snapshot of the evolution simulation has had and we hope it will stimulate further debate and thought as we move into the future.

Read the articleCASE STUDY

The text provides an in-depth account of Stefano Odorizzi’s journey in founding and growing EnginSoft, our engineering company specializing in computer simulation and modelling. Established in 1984, EnginSoft overcame early challenges, such as the high cost of computing, to emerge as a leader in simulation services, particularly in the fields of mechanical engineering and computational fluid dynamics (CFD). The narrative highlights several key milestones in the company’s history.

cfd metal-process-simulation industry4 news mechanics optimization

CASE STUDY

In this technical case study, EnginSoft was called in to assist in the application of Computational Fluid Dynamics (CFD) to model the flame size of a regeneration gas-fired heater for a project in Oman.

ansys mechanics energy oil-gas