New approach for accurate, robust morphing of CAD geometries

Facilitates bi-di transfer between analysis-testmanufacture and design

Newsletter EnginSoft Year 16 n°1

By Andrew Chinn | International TechneGroup

Connecting simulation and test results into the design process, such that analysis truly leads design, offers potentially significant breakthroughs for manufacturers.

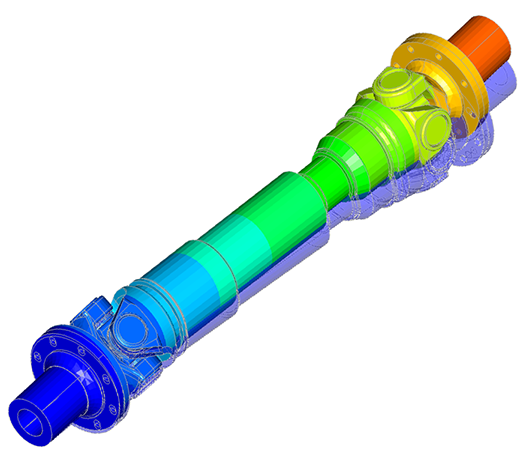

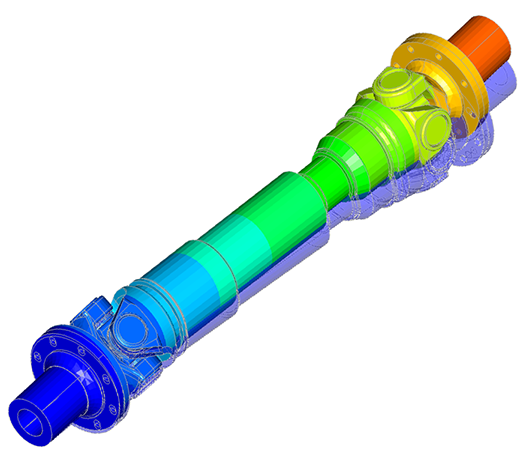

This technical article describes a new, automated approach to accurately and robustly morph CAD geometry based on results of analysis in order to facilitate the missing bi-directional transfer of these geometries between analysis/test/manufacture and design.

Two industrial examples using this approach are also provided, in the morphing of a turbine blade deformation model and aero-elastic deformation of aerodynamic shapes for the NASA Common Research Model. This technique is particularly useful for cases requiring multi-disciplinary analysis and automatic shape optimization for further, independent CAE analysis.

Read the articleCASE STUDY

Read the fascinating articles on the vast subject of structural engineering, beginning with a philosophical bent and arguing for the necessity of a skillful and artful intertwining of Engineering, Numerical Simulation, Art and Technology to achieve structures that are both eminently functional yet attractive and appealing.

civil-engineering

CASE STUDY

Menet Aero worked with Wolf Star Technologies to implement the True-Load load reconstruction software on their hexacopter drone. This project allowed Menet Aero to acquire valuable data on their drone designs, which can be used to optimize the weight and cost of their aircraft. The True-Load methodology proved to be an efficient and effective use of FEA models and testing techniques, providing a small investment in strain gauges for mission-critical data.

aerospace trueload