Innovation, digitalisation and sustainability have become key issues that companies must address to achieve and maintain a position of excellence, both nationally and internationally. In today's increasingly globalised and rapidly changing market, a company's survival sometimes depends on its ability to develop new products, optimise resources and modernise production cycles: in short, it is closely linked to investment in innovation and digitalisation.

But how do you implement engineering simulation technologies so that they are immediately effective and efficient? It requires careful analysis of the specific industrial reality, a deep understanding of its development potential and an accurate assessment of the return on investment - in other words, it requires specific skills in technological innovation and a lot of experience in the field.

EnginSoft has both: with forty years of experience and 4000 successfully completed projects, we have become a centre of excellence in the transfer of know-how, technologies and simulation software solutions in Italy and Europe.

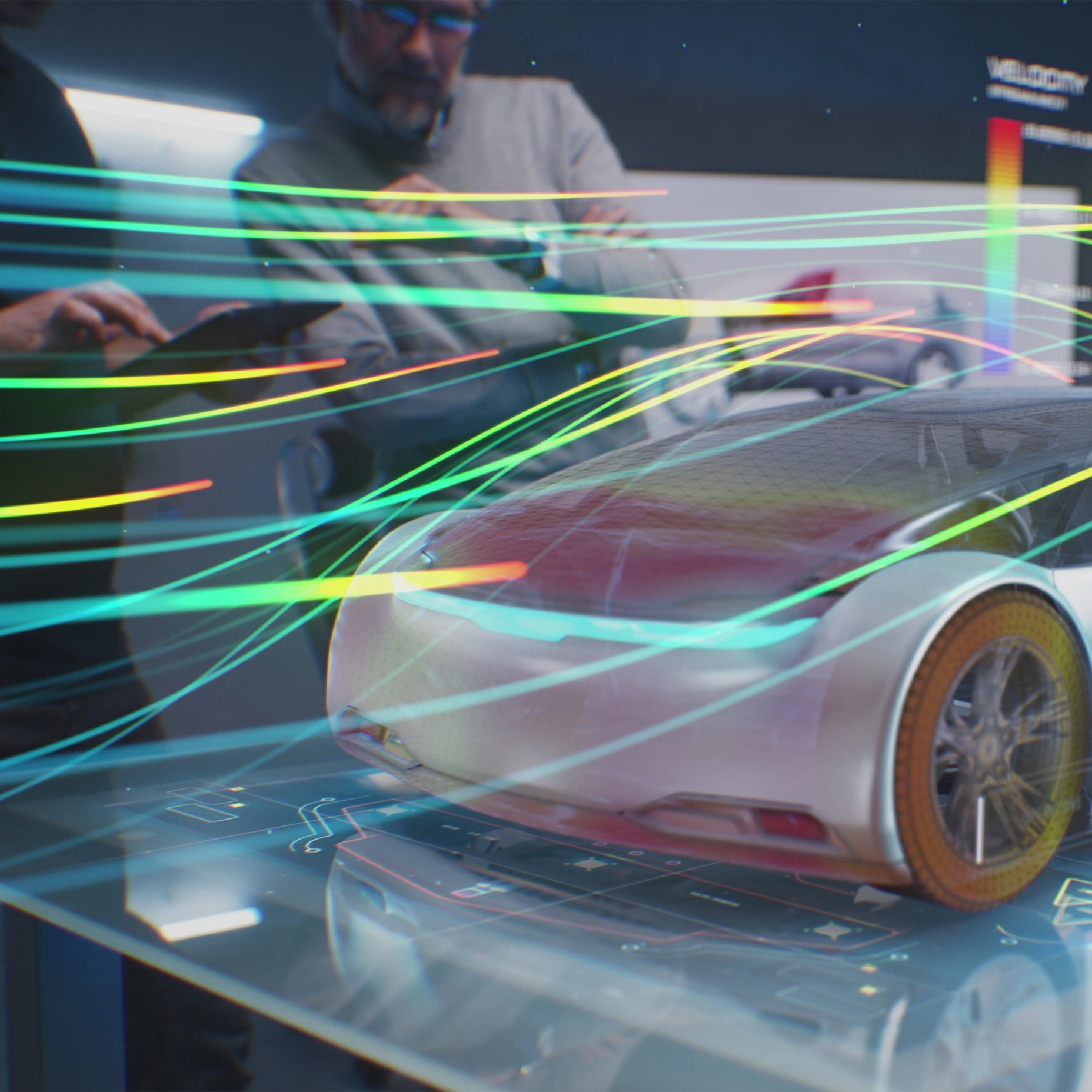

This is why we are able to implement and optimise "Simulation Based Engineering and Sciences", SBES, tailored to the specific production context, the particular needs and objectives of the company, ensuring the effective exploitation of the skills, methods and experience, the assets of the company with which we are called to collaborate.