Magma

Simulazione e ottimizzazione dei processi metallurgici

MAGMA è un prodotto MAGMA GmbH

MAGMA è un prodotto MAGMA GmbH

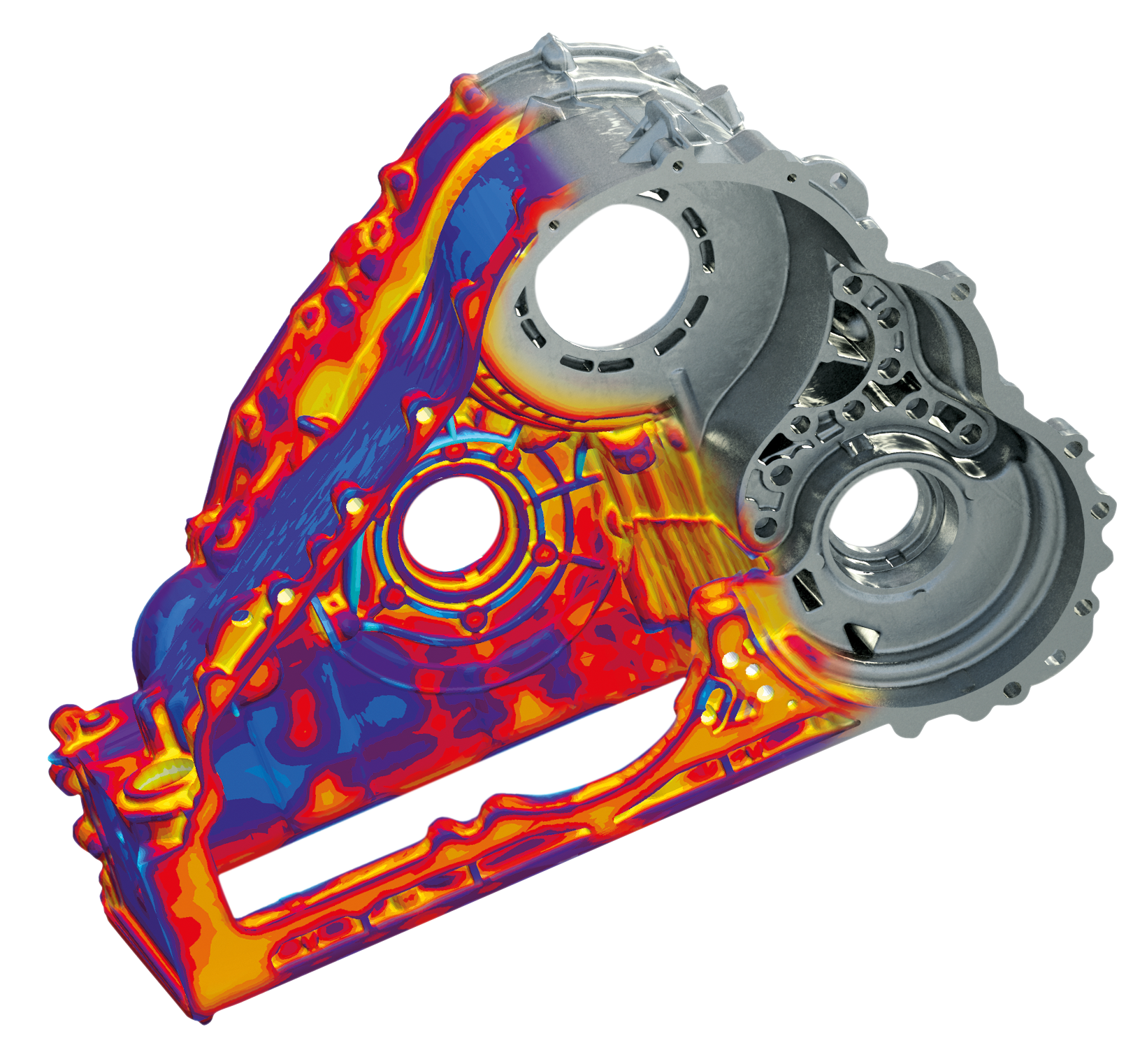

MAGMASOFT® è uno strumento di ottimizzazione completo ed efficace per migliorare la qualità della lavorazione dei metalli, ottimizzare le condizioni di processo e ridurre i costi di produzione. Utilizzando le metodologie "Virtual Design Experiments" e "Autonomous Optimization", è possibile stabilire parametri di processo affidabili e layout di fusione ottimizzati per tutti i materiali e processi di fusione, in modo efficiente e completo allo stesso tempo.

Attraverso l’Ottimizzazione automatica, le simulazioni con MAGMASOFT possono essere pianificate automaticamente per perseguire contemporaneamente obiettivi diversi di qualità e costo.

Questa soluzione software permette di simulare/ottimizzare l’intero processo di colata (riempimento, solidificazione e raffreddamento dentro e fuori lo stampo), comprendendo inoltre la fase di lavorazione meccanica (separazione dei componenti dai sistemi di colata e lavorazione dei sovrametalli) e di trattamento termico finale. La simulazione di processo può essere applicata con successo analizzando in dettaglio i risultati e i parametri di ogni tipologia di processo tramite i moduli dedicati, che consentono l'ottimizzazione delle fasi di riempimento e solidificazione con una affidabile previsione dei difetti e l'analisi termica degli stampi.

La sua applicazione si estende infine all'analisi delle tensioni residue (cricche a caldo, cricche a freddo, deformazioni) tipiche di ogni processo produttivo rivolta sia ai getti che agli stampi.

brochure

magma

brochure

Download the brochure "MAGMA C+M 6.0: Autonomous Engineering" - English version

magma

technical paper

This work describes as Tecnopress S.p.A., leader in die-casting components supply on a worldwide level, has applied the numerical optimization so to enhance the control on the production process of an automotive component, allowing to reachthe expected qualitative level without affecting the production cost.

magma

Invia le tue domande ai nostri tecnici specializzati!

Mettiti in contatto con uno dei nostri esperti, che ti potrà fornire risposte certe o consigliare soluzioni affidabili.

CASE STUDY

The adoption of SBES has significantly increased in the last two decades, driven by advancements in computing technology and the rise of Industry 4.0, which promotes nine key enabling technologies, including engineering simulation and big data analytics. SBES is crucial for the integration and automation of production systems, improving flexibility, speed, and quality.

automotive construction energy cfd metal-process-simulation

training courses

EnginSoft eroga corsi di addestramento su tecnologie software adatte alla simulazione di processi manifatturieri. I software di riferimento sono quelli prodotti da MAGMASOFT.

training magma metal-process-simulation