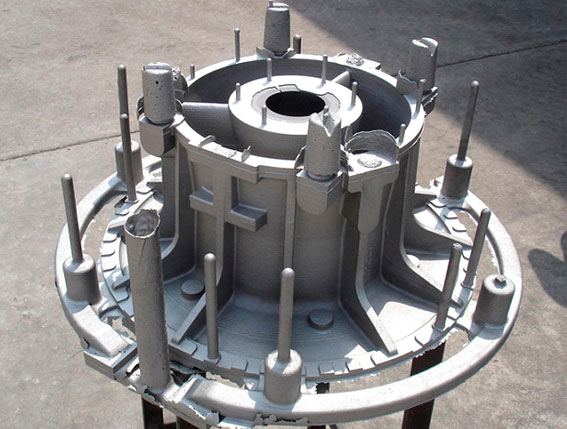

The Avio angular gearbox aluminum casing

Abstract

The scope of this study was to determine and validate a more efficient simulation procedure for the design phase of Al-Si alloy components for the aeronautical industry. The study combines the simulation of the manufacturing process with that of the component’s structural behavior to create a better predictive tool that is able to analyze the component’s behavior over its life cycle.

The study concludes that the detailed knowledge of the manufacturing process at its different stages, from casting to heat treatment and machining, and scale factors can be virtually implemented to find the optimal manufacturing process for the component’s reliability. This study was carried out by a team comprised of EnginSoft senior engineers and the Oeffevi foundry with the collaboration of AVIO and the University of Padua, Italy.