The Objectives of the Ring Rolling Study

ASFO Spa, part of the large rings division of the Fomas Group, is a world leader in the production of large rings that are produced using the hot ring rolling process. By large rings we mean rings that weigh up to 7000 kg, have external diameters of up to 4500 mm and ring heights of up to 1100 mm. To produce a high quality ring of this size, metal wastage is typically up to 40% of the final weight of the ring.

The objective of the study was to develop a finite element model to simulate the then current ring rolling process at ASFO Spa in order to match the level of post manufacturing defects encountered. The model was then used to produce a number of “what if” scenarios in order to find an optimal forging sequence that would substantially reduce defects incurred. The broader scope of the study was to improve compliance with design dimensional tolerances and to reduce the number of defects found following the manufacturing process.

Forge was chosen as the tool for these simulations because of its unique dedicated ring rolling module which offers:

- a very easy setup: the mandrel and radial rolls kinematics are derived automatically by Forge from the curves used by the mill operators

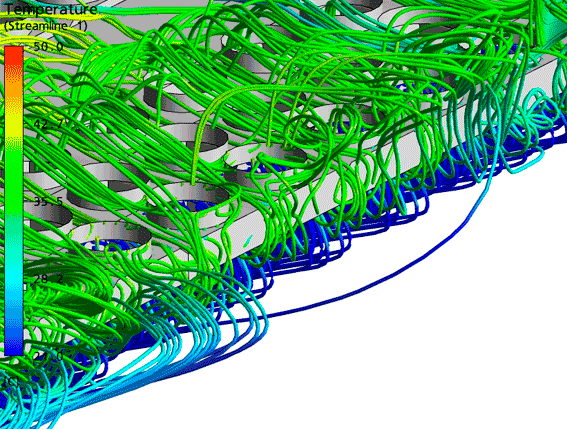

- an embedded ALE (Arbitrary-Langrangian-Eulerian) solver that provides a quick and accurate solution thanks to the reduced mesh deformation and faster convergence from improved numerical algorithms

Simulations for both the forging sequences of the pre-form and the ring rolling processes were performed. Based on the predictive capabilities of the Forge, a proposal was made to modify the forging sequence in order to reduce the number of post manufacturing defects encountered.