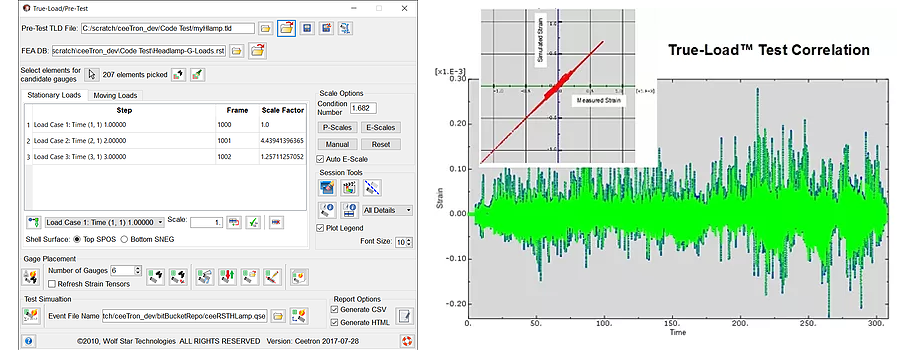

True-Load

Load Calculation Software for Product Engineering

True-Load è un prodotto Wolf Star Technologies.

True-Load è un prodotto Wolf Star Technologies.

Ogni ingegnere è consapevole che uno dei principali problemi delle simulazioni è la determinazione dei carichi che agiscono sulla struttura da dimensionare in base al suo reale utilizzo.

True-Load è il primo software presente sul mercato che sfrutta i modelli ad elementi finiti per posizionare in modo ottimale gli estensimetri sui componenti fisici senza modificarli e ricavarne i carichi a cui sono sottoposti durante i test.

True-Load si interfaccia direttamente con i principali software di calcolo presenti sul mercato e in particolare con i codici di fatica. In questo modo è possibile integrare in modo semplice ed intuitivo nel ciclo di progettazione i carichi reali agenti su una struttura e non, come spesso si è costretti a fare, quelli provenienti da studi eseguiti su progetti simili, o da esperienze pregresse. L’integrazione avviene in modo efficace ed al contempo semplice.

Invia le tue domande ai nostri tecnici specializzati!

Mettiti in contatto con uno dei nostri esperti, che ti potrà fornire risposte certe o consigliare soluzioni affidabili.

CASE STUDY

This article provides a non-exhaustive overview of some of the latest advances in the adoption of CAE technologies in the medical field by citing some ongoing EU research programs.

rbf-morph biomechanics

CASE STUDY

The purpose of the case study was to implement a design methodology that used multi-disciplinary simulation and an automated process to analyse thousands of product configurations and highlight vehicle performance distributions in terms of handling, comfort, and cost. This approach ensures that the best solution is always selected.

mechanics modefrontier automotive optimization

CASE STUDY

In this technical case study, EnginSoft was called in to assist in the application of Computational Fluid Dynamics (CFD) to model the flame size of a regeneration gas-fired heater for a project in Oman.

ansys mechanics energy oil-gas

CASE STUDY

This article proposes the use of computational fluid dynamics (CFD) to address these complexities.

ansys mechanics

CASE STUDY

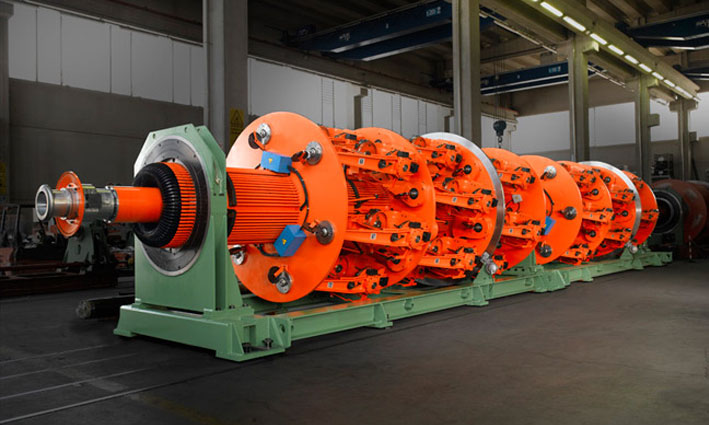

Stranding and closing planetary machines are huge pieces of equipment designed to twist multiple heavy spools of strand at noticeable speed, to manufacture large section steel ropes.

recurdyn multibody mechanics