Abstract

Despite recent technological advances in Artificial Intelligence and engineering, general purpose robots are still not a part of our everyday lives. Robots consist of multiple electrical and mechanical components and must possess great physical ability, versatility, and robustness to substitute or assist humans in either daily or dangerous tasks.

To create and deliver these types of products to market requires realistic models and CAE approaches to guarantee optimal and safe performance with a low production cost. This article presents an example of a proposed design optimization approach with a case study.

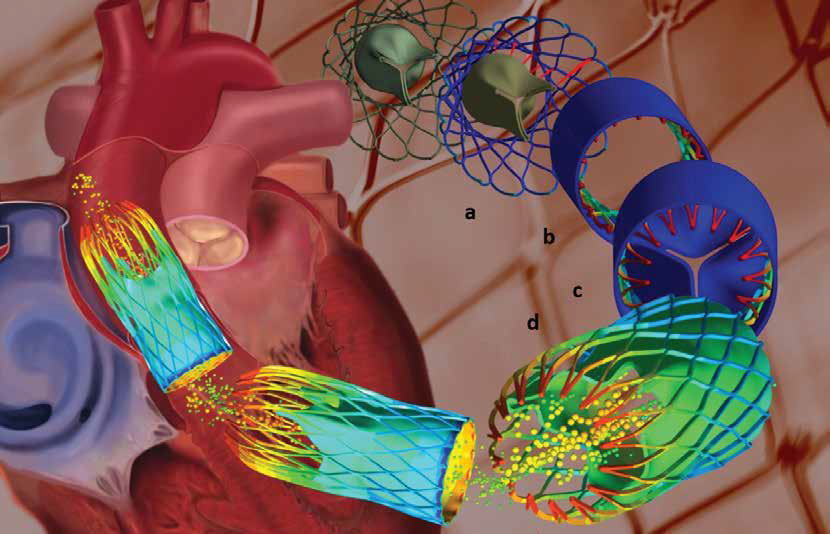

The results of this case study show that versatile robotic systems can be governed by complex trade-offs, which may depend on many factors including the system components, their combined behaviours

and limitations, and the tasks for which they are designed.

Moreover, in complex and highly dynamic electromechanical systems, typical optimization approaches tend to over-optimize the model, which results in theoretical performance that is unfeasible in practice.

In conclusion, building robots that are efficient physical actors is not an easy task, and designing them for widespread commercial use renders imperative the need for more systematic and scientifically

grounded approaches during their design process.

Read the article