Oorja

Innovative digital platform for the development and modeling of batteries, which simulates, predicts and optimizes their behavior

Oorja is a product of Oorja

Oorja is a product of Oorja

Two approaches are traditionally used in the design of a battery.

With the first, the behavior of a battery is simulated through the use of CAE (Computer Aided Engineering) technologies, which allow the product to be represented using numerical models focused on physics modeling and analysis. But, for an accurate prediction, it is necessary to introduce multi-physics analysis, i.e. to introduce further parameters, the electrophysical ones characteristic of batteries for example, which make the actual physical model more complex. To this we must add the increase in product complexity, determined by the introduction of new technologies and new materials, and by attention to environmental sustainability. And it is this complexity that has brought out the limits in adopting this approach: from the increasing calculation times, to the extensive skills that are required (on the software to be used, on the types of analyzes to be carried out, on the characteristics and behaviors of the new materials, to name the main ones).

The second approach, more recent, is instead linked to automatic learning models (Machine Learning). In this case, datasets are used to design a new battery, consisting of a large number of data collected experimentally.

But how reliable is this data when designing a new product? The design and performance of a battery depend on many factors: the limit in using this approach is the availability of data that is actually useful in the early design phases.

Oorja fits into this scenario: the strength of this platform lies in the adoption of a hybrid approach, which exploits the advantages of the two methodologies described above, and overcomes their limitations.

Oorja uses an approach based on simple and fast physical models, which will form the basis for the machine learning algorithm, thus reducing the number of data needed for the initial dataset.

Oorja simulates, predicts and optimizes the behavior of batteries, analyzing different performances, such as, for example, the quantity of current produced, the "capacity/power fade", overheating during use, fast charging protocols and related aspects to the guarantee.

At the basis of the methodology there is a workflow made up of 7 modules:

To underline the extremely "user friendly" graphic interface of Oorja, which makes the use of the complex methodology extremely simple: it is based on the use of a "wizard", i.e. an automatic system, which guides the user step by step in workflow generation.

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

This article details a study that was undertaken by Castel, a producer of refrigeration and air conditioning components, to compare the results of an experimental method for testing expansion valves with a numerical method using Ansys.

ansys energy

CASE STUDY

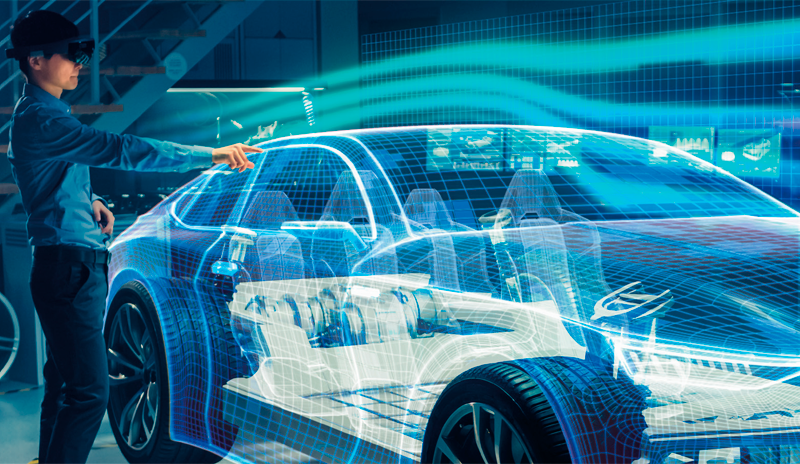

Futurities interviewed Paul Stewart about his thoughts on the evolution of simulation’s role in the design process in the automotive industry, the evolving roles of CAD and CAE and the move to freeform deformation in automotive design, as well as the likely impact and role of artificial intelligence technologies in this space.

automotive

Our competences in Oorja

CASE STUDY

The growth of technology and end-user expectations is ever more important in many application areas and medical devices are at the forefront of this innovation process.

ansys electronics

CASE STUDY

In this case study, EnginSoft engineers explain how they used modeFRONTIER to assist Comau, a Fiat Chrysler subsidiary, to optimize their approach to the preliminary design of production systems for automotive manufacturing system RFQs.

automotive optimization rail-transport modefrontier SIMUL8 iphysics industry4

CASE STUDY

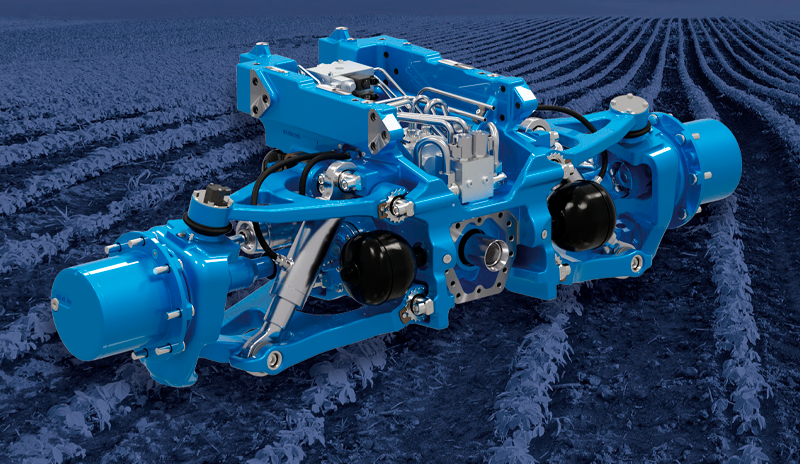

The purpose of the case study was to implement a design methodology that used multi-disciplinary simulation and an automated process to analyse thousands of product configurations and highlight vehicle performance distributions in terms of handling, comfort, and cost. This approach ensures that the best solution is always selected.

mechanics modefrontier automotive optimization