X-RHEA

The Real Power of Simulation

X-RHEA is co-developed by EnginSoft and Vection Technologies.

X-RHEA is co-developed by EnginSoft and Vection Technologies.

X-RHEA (EXtended Reality for Human Engineering Application) is the immersive solution for the visualization and presentation of CAE (Computer-Aided Engineering) data.

The goal of X-RHEA is to enhance the presentation of studies and simulations to expedite comparison sessions among multidisciplinary teams and simplify technical-commercial communication.

X-RHEA is a cutting-edge suite to visualize in extender reality any engineering simulation results. This innovation merges tradition with modern technology, providing a powerful tool. X-RHEA revolutionizes technical-commercial communication, turning complex 2D reports into immersive experiences on Industrial Metaverse and enabling Artificial Intelligence integration.

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

This technical case study describes how the ROPS and FOPS of a tractor were numerically studied in the early design phase to ensure compliance with OECD Standard Code 4 (for the cabin’s resistance to longitudinal, lateral and vertical energy or force) and Code 10 (for overhead protection from falling objects).

automotive rail-transport ls-dyna

training courses

The training course on geometric product specification and tolerance analysis addresses the issues related to tolerance management and the approach known as "Dimensional Management", which defines the activities involved and their sequence for achieving the desired quality at the lowest possible cost. We offer a wide range of training courses – scheduled, on-demand and customized – designed to meet the varying needs of individuals and/or the company in which they work: SO-GPS, ASME-GD&T standards, Tolerance analysis and model-based definition, and Software technologies training.

cetol tolerances

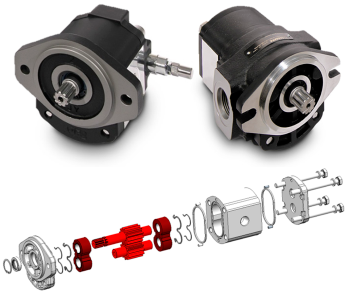

CASE STUDY

In this technical case study, EnginSoft assists Casappa to further refine an already-optimized standard series pump for an electrical motor and generator

mechanics optimization modefrontier

CASE STUDY

In a recent interview, Enrico Boesso (EnginSoft) and Daniel Campbell (Capvidia) discussed how Model-Based Definition (MBD) is transforming manufacturing by replacing traditional 2D drawings with data-rich 3D models as the "single source of truth".

comparevidia mbdvidia tolerances digital-manufacturing mechanics

CASE STUDY

In this article, Del Negro explains how Ricardo is developing solutions to support its customers to predict the lifecycle of motorcycle components, using finite element analysis (FEA) and fatigue analysis.

femfat mechanics automotive