Materials and Additive Manufacturing

The project "TEMART - Technologies and materials for artistic manufacturing, Cultural Heritage, furniture, architectural and urban design and the design of the future" aims to improve the products of the above-mentioned sectors (functionality and aesthetics) by applying the different technologies available from the M3NET Regional Innovation Network.

The project aims to enhance the technical-scientific knowledge and the ability to develop new combinations of manufacturing technologies and materials to meet the needs and capacity for innovation in the domains of artistic craftsmanship, restoration of Cultural Heritage, furniture and design. Therefore, innovative technological applications will be studied, developed and validated, to support prototyping and producing components and products of artistic and design value in which the complexities of the form and the material are combined with multifunctionality. The innovation applied to additive manufacturing technologies for an extended range of materials and their combinations in the same artifact will be particularly relevant.

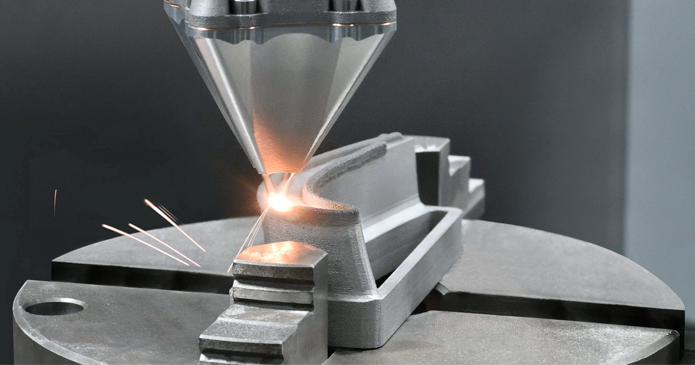

The project provides for an integration among cutting-edge technological platforms, both in the field of additive manufacturing, and in the modeling and characterization of surfaces including engineering, as well as in subtractive processing including laser.

These technological platforms are developed to support the needs of the industrial partners ranging from industrial fields of advanced manufacturing, design, up to artistic creation activities.

Furthermore, the decision support system (DSS) enables the industrial partners to assess and reduce the risk associated with the adoption of innovative technological platforms, providing them with an aid to the product and process innovation and a corresponding consistent strategic advantage.

EnginSoft designed and implemented a Decision Support System (DSS) to assist companies and research centers in the Veneto region in the development and integration of technologies and processes. Thanks to the DSS, the value of the project goes far beyond the development of relevant case-based solutions. In fact, the different knowledge and experiences acquired, systematized and organized through the DSS, are accessible and usable by all the project partners during the same and by the entire industrial and research system of the Veneto Region.

Finally, EnginSoft supported the design phase of a cold crucible for the vacuum or inert atmosphere microcasting of refractory alloys requiring a high degree of purity. In particular, it supported the component and process design phase by simulating the additive process of metal powder bed laser melting in order to identify the optimal print layout. The orientation of the piece on the printing platform, the support strategy and the dimensional tolerance of the product have been optimally defined by geometric compensation.

CONSORZIO M3 NET, COCCO GABRIELE, CONSORZIO CLUSTER MANAGEMENT NETWORK, COOPSERVICES SOCIETÀ COOPERATIVA, DELKA SRL, DFF SRL, ECOR INTERNATIONAL SPA, ENGI SRL, ENGINSOFT SPA, FRANCESCON SRL, KAZAN, METAL FINISH SRL, MORELLO GIANLUCA SRL, OFFICINA DEI MATERIALI DI ANTONIO ALESSANDRO ROSSI & C. SAS, P. FACTOR SRL, PRS SRL, PRISMATECH SRL, RETE DI IMPRESE LUCE IN VENETO, STUDIO 4 SRL, UNIVERSITÀ DEGLI STUDI DI PADOVA, UNIVERSITÀ DEGLI STUDI DI VENEZIA - IUAV, UNIVERSITÀ VENEZIA - CÀ FOSCARI, UNIVERSITÀ DEGLI STUDI DI VERONA, VAR CONNECT SRL, VENETIAN HERITAGE CLUSTER SRL.

Funding Scheme POR - Obiettivo "Incremento dell'attività di innovazione delle imprese" - Parte FESR fondo europeo di sviluppo regionale 2014 - 2020

“Progetto finanziato con il POR FESR 2014-2020 Regione del Veneto” - ASSE 1 “RICERCA, SVILUPPO TECNOLOGICO E INNOVAZIONE” AZIONE 1.1.4 “Sostegno alle attività collaborative di R&S per lo sviluppo di nuove tecnologie sostenibili, di nuovi prodotti e servizi”

"Project co-funded by POR ERDF 2014-2020 Regione del Veneto" - AXIS 1 "RESEARCH, TECHNOLOGICAL DEVELOPMENT AND INNOVATION" ACTION 1.1.4 "Support for collaborative R&D activities for the development of new sustainable technologies, new products and services"

Importo finanziamento: € 2.430.030,39 / Grant Amount: € 2.430.030,39

36 months

November 2017 - October 2020

RIR “M3-NET Meccanica di precisione, Micro-tecnologie e Manifattura additiva”

Giovanni Borzi - Nicola Gramegna

25

by Nicola Gramegna | EnginSoft

Antonio Rossi | AddtoShape

Futurities - Summer 2023

The TEMART project aimed to use simulation software to model the physical phenomena at play during levitative metal melting, and to optimize the technological process of additive manufacturing with pure copper. The main objective of this study is to demonstrate how additive technologies combined with simulation methods can enable continuous progress in the creation of innovative and efficient products. The component being studied is a crucible for the controlled melting of metal.

Read the article

Some of our competences in research and technology transfer

Research project

The objective was to design, study and characterize the atmospheric sub-system of a Plant Control Unit and its processes related to crop growth. The atmosphere of the plant-related environment had to be homogeneous and meet the plants’ requirements.

Research project

The final goal of the project is to define a technology solution to repair metal components. End users require an automated or semi-automated solution for mounting a part of partially unknown shape into a machine, measuring the relevant part of its surface in 3D and automatically generating a repair program to restore it to the desired shape.