Smart Manufacturing

Within the foundry industry, large castings (weighing up to several tens of tons), used for power generation or machine tool applications, constitute a range of products with extremely high added value. These castings are made primarily of steel or cast iron, depending on their intended use or performance. Paradoxically, the realization of these products, which have exceptional quality requirements, still requires laborious manual processes to be carried out by the operator (polishing, grinding, deburring, etc.). These procedures cause significant ergonomic and vibro-acoustic comfort problems for operators, potentially leading to occupational diseases.

The Project therefore aims to:

The robotic equipment developed by the project for grinding, deburring, de-scoring and repairing castings is a first for most ferrous alloy foundries. The direct benefits that can be identified are varied:

EnginSoft is responsible for the mechanical design of the robotic solutions, and the vibro-acoustic simulations.

ADI TOOLS SPA, BNP SRL, BUSON SRL, ENGINSOFT SPA, FONDERIA CORRA' SPA, IT+ROBOTICS SRL, SAFAS SPA, UNIVERSITA' DI PADOVA - DTG.

Funding Scheme POR - Obiettivo "Incremento dell'attività di innovazione delle imprese" - Parte FESR fondo europeo di sviluppo regionale 2014 - 2020

"Project co-funded by POR ERDF 2014-2020 Regione del Veneto" - AXIS 1 "RESEARCH, TECHNOLOGICAL DEVELOPMENT AND INNOVATION" ACTION 1.1.4 "Support for collaborative R&D activities for the development of new sustainable technologies, new products and services"

“Progetto finanziato con il POR FESR 2014-2020 Regione del Veneto” - ASSE 1 “RICERCA, SVILUPPO TECNOLOGICO E INNOVAZIONE” AZIONE 1.1.4 “Sostegno alle attività collaborative di R&S per lo sviluppo di nuove tecnologie sostenibili, di nuovi prodotti e servizi”

Importo finanziamento: € 1.007.700,00 / Grant Amount: € 1.007.700,00

36 months

November 2017 - October 2020

CONSORZIO SPRING

Nicola Gramegna

9

by G. Morandina, A. Trevisan | EnginSoft

P. Pasqualotto, M. Chiodin | SAFAS

A. Trevisani, D. Richiedei | University of Padua

A. Ragazzon, A. Parolin | BNP

Futurities - Summer 2022

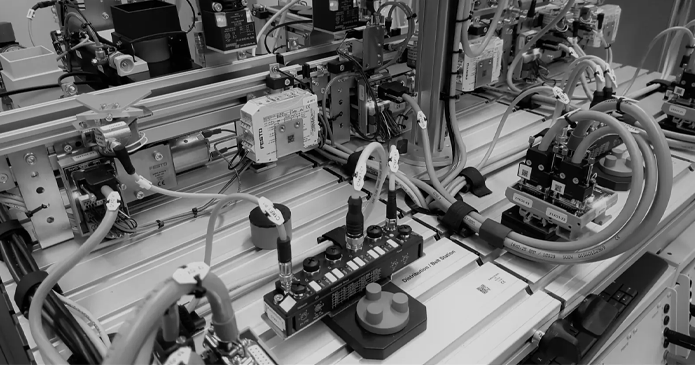

The FORSAL project has successfully designed and prototyped a system that reduces the vibrations transmitted to operators by the grinders used for the finishing processes on foundry castings. This article introduces the ergonomic issues related to grinding operations, and then focuses on the design and validation of a vibration reduction system that can also be used outside the foundry environment.

Read the article Read the article

Some of our competences in research and technology transfer

Research project

The overall objective of the TECNOMED-HUB project is to create, in the Piedmont region of Italy, a technology platform to support medical research 4.0, based on the integration of existing multi-omics platforms with self-learning algorithms, data mining, and big data analytics.

Research project

Metal Additive manufacturing is a complex operation that requires the fine-tuning of hundreds of processes parameters to obtain repeatability and a high quality design at dimensional, geometric, and structural levels. To help manufacturing companies address these challenges, AMQ_TOOLS develops an innovative quality-oriented decision support framework.

Research project

The goal of the project was to design a full Plant Characterization Unit (PCU) chamber with a completely sealed environment for the plants and roots. The designed plant control unit inherited the know-how from two previous projects, HySSE and AtSSE.