Ansys Composite PrepPost

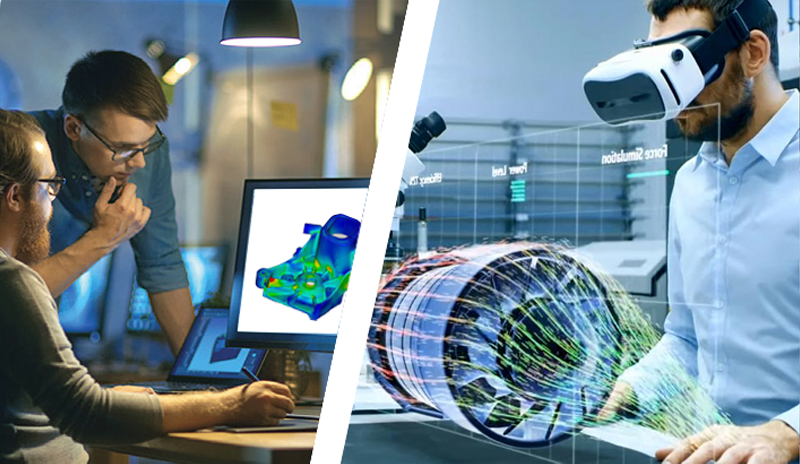

A user-friendly approach to analyze composite material structures

Ansys is a software suite of Ansys Inc.

Ansys is a software suite of Ansys Inc.

Lightness, strength and versatility of composite materials make them attractive for multiple applications, especially if the aim is to achieve high-level mechanical performance. To properly set up a FEM simulation using these materials, it is necessary to consider their composite nature, the directionality of the mechanical properties and the need to define laminates through a layered approach.

Ansys Composite PrepPost (ACP) is an integrated tool in the Workbench platform dedicated to composite laminates modeling (Pre) and advanced analysis results (Post) using dedicated failure tools.

ACP allows to generate FEM models with different lamination regions defined layer-by-layer, it uses the Ansys Mechanical solvers to perform implicit / explicit structural and thermal simulations, as well as fluid-structure interactions. Starting from the definition / choice of the material data (UD, Fabric, Stack-up), in the Pre-processing phase ACP allows to properly define stacking sequences to cover the entire structure. It's possible to switch from shell to solid modeling for submodeling analyzes or to study debonding and delamination effects. Draping simulation and "flat wrap" results are available on double curvatures surfaces.

In the Post-processing phase, ACP allows to perform global and local failures, also analyzing out-of-plane stress components and foreseeing delamination and debonding phenomena. ACP also allows the exchange of model information through various formats (e.g. Excel), including the vendor-independent CAE *.HDF5 format which enables communication with third-party tools.

Request a free demo

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

This study discusses the complex and challenging problem of controlling vortex-induced vibrations (VIV).

cfd mechanics ansys rbf-morph

Our competences in Ansys Composite PrepPost

CASE STUDY

This article examines the simulation of an RCD to determine the factors that affect its response times.

appliances ansys cetol recurdyn tolerances

CASE STUDY

Two main reasons have been the drivers for introducing and using CAE simulation technologies and mathematical modeling: safety and achieving optimal design.

ansys energy

CASE STUDY

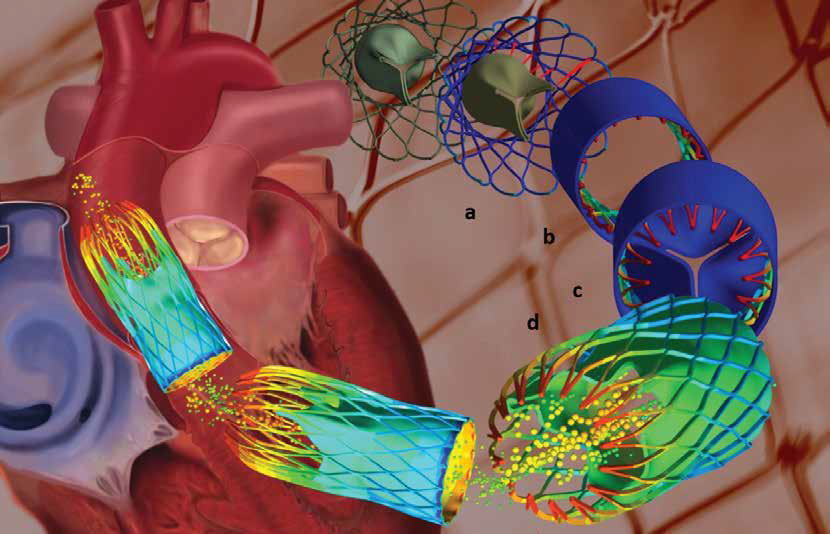

This technical article describes how high-end numerical Computational Fluid Dynamics (CFD) simulations were applied to mimic the realistic operating conditions of a Ventricular Assist Device (VADs) and analyze its hemodynamics in order to identify potential areas for optimization of the device’s performance, safety and efficacy.

ansys cfd biomechanics

CASE STUDY

Marelli Motori engineers use Ansys multiphysics solutions to custom-design motors and generators to solve challenges in hydropower, cogeneration, oil and gas, civil and commercial marine transport, military applications, and ATEX applications involving motors and generators in explosive atmospheres, among other applications.

automotive ansys energy

CASE STUDY

Elettronica SpA designs and produces systems for electronic warfare. Each system design is unique according to its platform and purpose. In this article, the company describes how it used CAE to approach the challenging design of a single sandwich radome.

ansys optimization electronics

CASE STUDY

EnginSoft implemented a new 3D CFD multi-phase model to simulate the water condensation-evaporation processes inside automotive headlamps for Automotive Lighting, a leading supplier of quality headlights to the OEM market

automotive cfd ansys rail-transport

CASE STUDY

The objective of the study was to create a virtual model of Climaveneta’s new ACU171 Expanded Close Control Unit and then match the numerical results with the experimental measures.

cfd ansys appliances

CASE STUDY

At this particular moment in time, this article wishes to reflect on the evolution of CAE and simulation in an effort to present a big-picture view when most of us are daily dealing with all the devil in the details in every aspect of our lives. We approached some long-standing business friends in engineering simulation from various regions around the world to help us in this task

ansys industry4 news

CASE STUDY

The purpose of the case study was to implement a design methodology that used multi-disciplinary simulation and an automated process to analyse thousands of product configurations and highlight vehicle performance distributions in terms of handling, comfort, and cost. This approach ensures that the best solution is always selected.

mechanics modefrontier automotive optimization

CASE STUDY

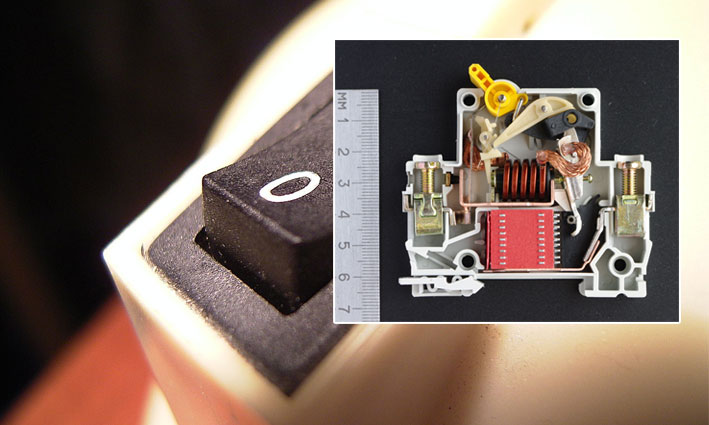

The premium software RecurDyn was used to simulate a Double Pole Single Throw Switch using three different modeling schemes. A comparison of the results provided useful information for the designers.

recurdyn mechanics multibody

CASE STUDY

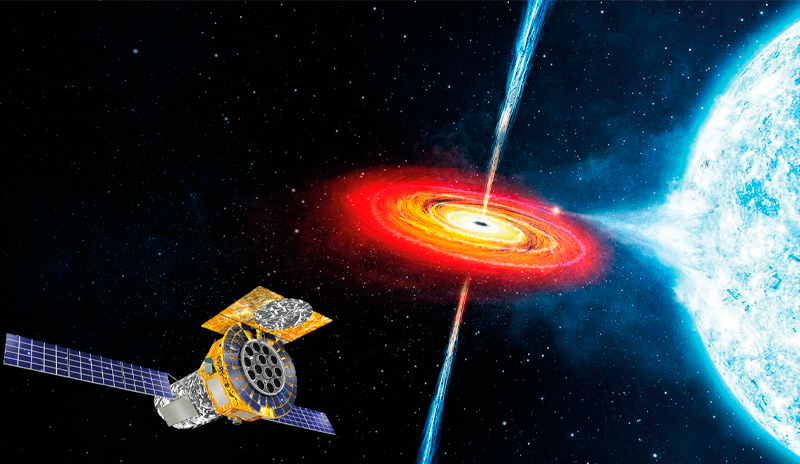

This article describes the preliminary study resulting in the design solutions adopted for the LAD module’s most important thermo-mechanical drivers, which were developed and used to demonstrate compliance with the system requirements at the spacecraft level.

aerospace rbf-morph ansys

CASE STUDY

Lovato Electric is committed to delivering innovation through its products and so it commissioned EnginSoft to help it create a pilot project in order to compare and finally select an electromagnetic field simulation software solution.

ansys electronics

CASE STUDY

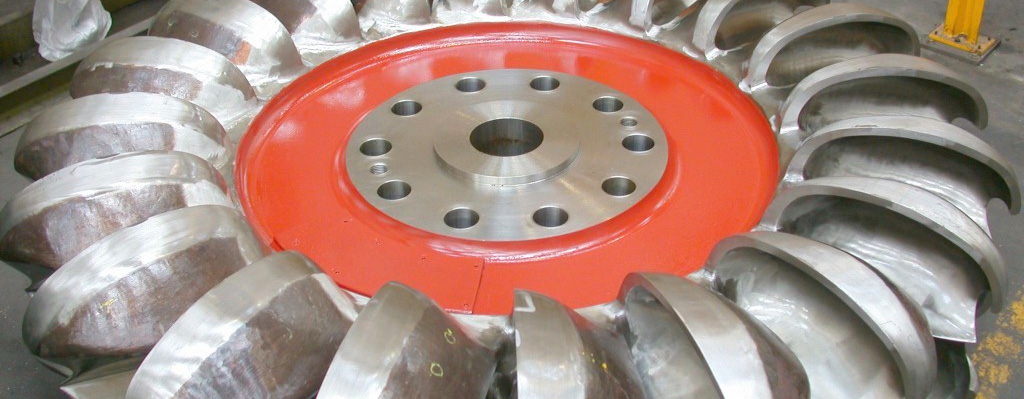

EnginSoft developed a Computational Fluid Dynamic (CFD) analysis methodology for the performance evaluation of a Pelton turbine

energy cfd ansys oil-gas

CASE STUDY

Traditional naval architecture meets the CFD analysis with the aim to improve consolidated products reaching values in terms of performance never seen before.

ansys cfd marine

CASE STUDY

Transmission design is mainly based on the mechanical aspects of the transmission and lubrication is an aspect that is verified, and eventually corrected, based on bench testing, i.e. once the design phase has been completed and a physical prototype is available.

mechanics particleworks automotive

CASE STUDY

Cimolai Technology explains the business benefits it has achieved since the installation in terms of time savings in planning, and design, and improvements in product quality and in delivery forecast ability.

ansys mechanics rail-transport marine

CASE STUDY

Since this cannot be accurately measured in an implanted stent, manufacturers decided to use Multiphysics to simulate the process to better understand the method and to calculate the forces operating on the implant in order to improve the stent design and the surgical procedure, as described in this article.

cfd biomechanics ansys

CASE STUDY

This article describes how SAER ELETTROPOMPE used Ansys CFX to transform "standard" pumps into pumps to be used as turbines.

energy ansys cfd

CASE STUDY

This article proposes the use of computational fluid dynamics (CFD) to address these complexities.

ansys mechanics

CASE STUDY

The model contains both rigid and flexible bodies: the pin was modelled using the proprietary Full Flex technology which includes a Finite Element body in the dynamic simulation.

recurdyn mbd-ansys automotive multibody

CASE STUDY

This project investigates how best to correctly predict the energy absorption of these non-isotropic and non-homogeneous materials, whose lamina thickness is typically of the order of 0.2 mm or less and consists of tiny fibers or particles dispersed in a matrix material.

ls-dyna aerospace composites

CASE STUDY

A fascinating article on the origin, history, and evolution of roller coasters from their earliest prototypes in Russia in the 16th century on the banks of the Neva River of St. Petersburg, and then dives into detail on how numerical simulation of roller coasters works to ensure their success both as entertainment and from a safety perspective for users and operators.

mechanics civil-engineering construction optimization

CASE STUDY

This technical article describes how CFD analysis minimizes trial and error activities and costs and improves RFT – “right first time” – results.

consumer-goods cfd furniture ansys

CASE STUDY

This paper demonstrates how the biological growth method, studied by Mattheck in the 1990s, can be easily implemented for structural shape optimization finite element method (FEM) analyses using advanced radial basis functions (RBF) mesh morphing.

ansys biomechanics rbf-morph

CASE STUDY

The bridge represents an example of a cable stayed mixed steel-concrete structure, where the stay cables are asymmetrically connected to the center of the deck and to the top of the central transverse steel arch.

construction civil-engineering ansys straus7

CASE STUDY

This article provides a non-exhaustive overview of some of the latest advances in the adoption of CAE technologies in the medical field by citing some ongoing EU research programs.

rbf-morph biomechanics

CASE STUDY

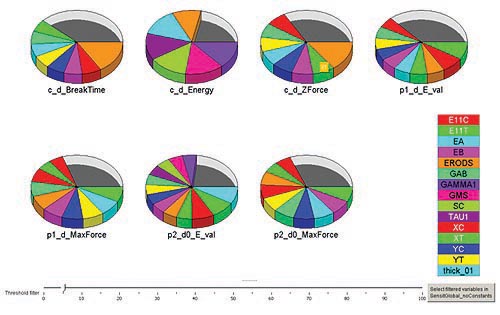

While the engineers relied on modeFRONTIER's capabilities, the procedure has been to calibrate the constitutive parameters of LS-DYNA's advanced material models, and to use them for prediction, design optimization and robustness analysis.

modefrontier ls-dyna automotive composites

CASE STUDY

This technical article describes an acoustic emissions study conducted on an electric water circulation pump used for supplementary cooling or heating functions in vehicles, by the Modeling & Simulation Pumps Department of Pierburg Pump Technology

acoustic ansys mechanics

CASE STUDY

This article describes how the company created and tested a process to construct a parametric CAD model capable of providing its designers with a starting point for any new machine to be designed.

mechanics ansys modefrontier maplesim maple

CASE STUDY

The Extremely Large Telescope (ELT) is a 40m-class optical and infrared telescope being built in Chile. The ELT has a complex geometry, with a rotating structure and a dome that must be protected from wind effects to ensure accurate observations. To study the wind flow within the dome, a computational fluid dynamics (CFD) model was created.

civil-engineering cfd ansys

CASE STUDY

This case study details the design optimization of an axial steam turbine of 160 MW, focusing on maximizing the total-to-total isentropic efficiency of the last three low-pressure stages of the turbine.

cfd ansys turbomachinery modefrontier

CASE STUDY

This technical article describes a human body model (HBM) wizard developed for RecurDyn and discusses what is already possible and what is in the development pipeline for the near future. Biomotion Solutions provides software to quickly build HBMs in industrial-grade simulation packages.

multibody recurdyn industry4 biomechanics

CASE STUDY

Nederman’s Air Purification Tower is the perfect choice if source extraction is not a satisfying option.

ansys mechanics

CASE STUDY

This article describes how EnginSoft applied a Computational Fluid Dynamics (CFD) analysis, on behalf of Whirlpool EMEA, to simulate three different geometrical design modifications to the vacuum cleaner head to improve on a baseline performance that was modelled first.

appliances cfd ansys

CASE STUDY

In this article, Del Negro explains how Ricardo is developing solutions to support its customers to predict the lifecycle of motorcycle components, using finite element analysis (FEA) and fatigue analysis.

femfat mechanics automotive

CASE STUDY

This technical article discusses some of the problems of using finite element method (FEM) simulation software for composite material analysis and introduces new solutions from CYBERNET with Ansys Software for solving these problems.

composites ansys multiscale

CASE STUDY

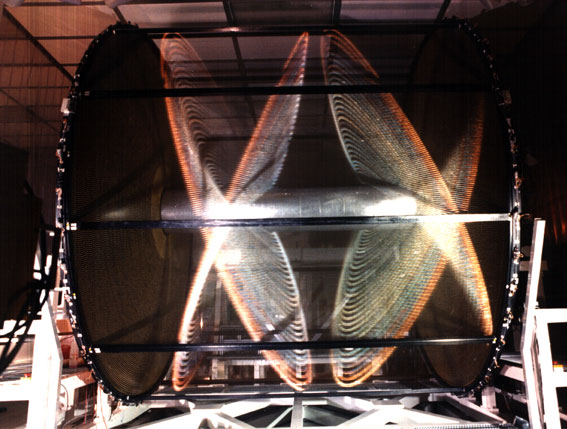

The ultimate goal of the study was to optimize the Drift Chamber’s performance in terms of stiffness, strength and weight o be mounted on the Mu2e particle detector at FermiLAB in Chicago

construction modefrontier ansys optimization energy

CASE STUDY

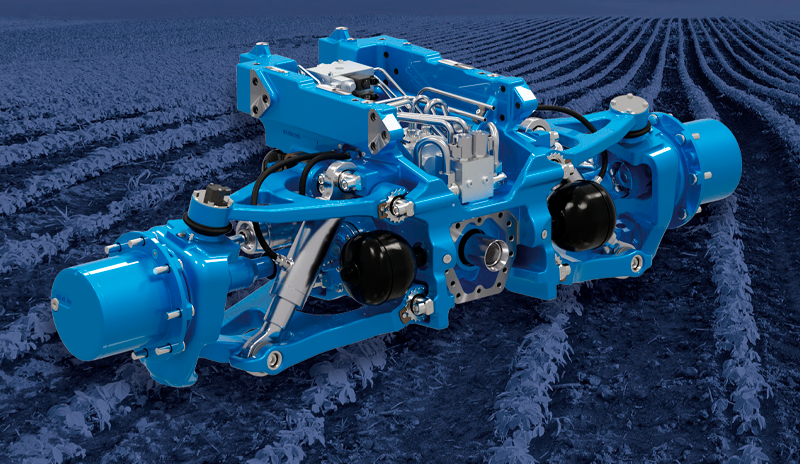

This case study describes how the company’s R&D team used ANYSYS and Spaceclaim to conduct Finite Element Method analyses to refine the design of a new model of a sprayer boom used by farmers to distribute phytosanitary products over fields for crop protection.

ansys automotive rail-transport

CASE STUDY

This article discusses a multi-objective optimization study to determine the optimal matrix for the routing of the actuating cable system in order to minimize the cable load on the robot and maximize the robot’s payload.

optimization modefrontier mechanics electronics

CASE STUDY

In this article, Uteco describes how it applied Computational Fluid Dynamics (CFD) to assist the design and improvement of its printing machines.

cfd ansys mechanics

CASE STUDY

Simulation is nowadays strongly connected to new product development in most high-technology industries.

ansys electronics

CASE STUDY

In this example, these features were tested by simulating the motion of a very thin plastic film (32µm) being dragged by two rollers.

recurdyn mbd-ansys mechanics multibody

CASE STUDY

This technical article describes a numerical (transient computational fluid dynamics) simulation applied to study the suction efficiency of a canopy hood in a steel plant’s electric arc furnace with a view to increasing it.

ansys energy

CASE STUDY

Stacker cranes handle pallet placement in the warehouse, moving longitudinally along the aisles between the warehouse shelves to deposit and retrieve loads. Stacker cranes are susceptible to earthquakes that can damage them and the racks around them.

mechanics civil-engineering

CASE STUDY

This article presents an example of a proposed design optimization approach with a case study.

biomechanics modefrontier

CASE STUDY

Special Springs commissioned EnginSoft’s engineers to calculate the production cost repercussions of a technical product modification requested by an important customer.

eztol mechanics cetol tolerances

CASE STUDY

A client wanted to evaluate the dynamic performance of a new-concept forklift, so a fully-functional multibody model of the forklift was built by assembling the client’s CAD geometries.

multibody automotive mechanics recurdyn

CASE STUDY

The article focuses on the difference in fatigue behaviour between rubber and metal materials. While metal fatigue is often described by a simple rule: increasing mean strain is detrimental to fatigue life, rubber fatigue is more complex and depends on the material's ability to strain crystallize. The text concludes that while tensile mean stresses are always detrimental in metals, in rubber they may be either beneficial or harmful depending on whether the rubber can strain crystallize.

mechanics endurica automotive

CASE STUDY

This paper, by means of presenting three application cases, provides a brief description of the capabilities of a numerical tool developed for the design and optimization of hybrid metal/composite lattice structures created with 3D printing

ansys composites

CASE STUDY

This study discusses the complex and challenging problem of controlling vortex-induced vibrations (VIV).

cfd mechanics ansys rbf-morph

CASE STUDY

Multibody simulation is integral to engineering, enabling precise analysis of structural loads and dynamic behaviours in complex systems. In the context of forklifts, where tyres play a critical role due to the absence of suspension systems, accurate tyre modelling is essential. This study develops and validates a hysteretic Bouc-Wen model for the radial dynamics of solid rubber tyres to enhance simulation reliability.

multibody recurdyn mechanics automotive

CASE STUDY

Racing engines are continuously evolved and fine-tuned to allow them to achieve extraordinary levels of performance, albeit with great complexity. However, MotoGP regulations restrict engine development by constraining some of the main design parameters.

optimization modefrontier cfd ansys rail-transport

CASE STUDY

Further reduction of the heat loss compared to the best design of the NSGA-II first phase design optimization: a further 4% gained

cfd biomechanics ansys modefrontier optimization

CASE STUDY

The final portion of the paper path of a laser printer has been studied using the Media Transport Toolkit to evaluate the influence of the corrugating roller which is used to corrugate the sheet to keep it straight before falling into the tray.

recurdyn multibody mechanics consumer-goods

CASE STUDY

This article details a study that was undertaken by Castel, a producer of refrigeration and air conditioning components, to compare the results of an experimental method for testing expansion valves with a numerical method using Ansys.

ansys energy

CASE STUDY

Faber Spa, which has designed and manufactured ventilation hoods for the past 50 years, holds a key global position both in terms of production and technology. It has achieved this position through strategic investments in research and development.

ansys appliances consumer-goods cfd

CASE STUDY

This article presents a study that the Elica Group commissioned from EnginSoft to support it engineering team in redesigning the ventilation system of its “Tilly” kitchen hood model

appliances ansys cfd

CASE STUDY

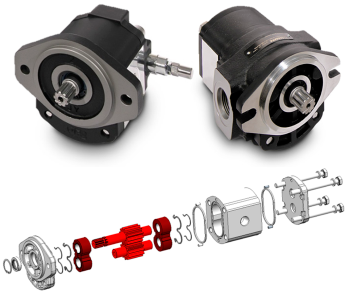

In this technical case study, EnginSoft assists Casappa to further refine an already-optimized standard series pump for an electrical motor and generator

mechanics optimization modefrontier

CASE STUDY

The study described in this article was designed to obtain greater insight into the gas transfer mechanism at microscopic scale using computational fluid dynamics in order to accelerate design exploration to find the optimal solution.

biomechanics ansys

CASE STUDY

ptimization of the product starts with a strong correlation of the model with specifically designed tests under controlled conditions.

ansys automotive

CASE STUDY

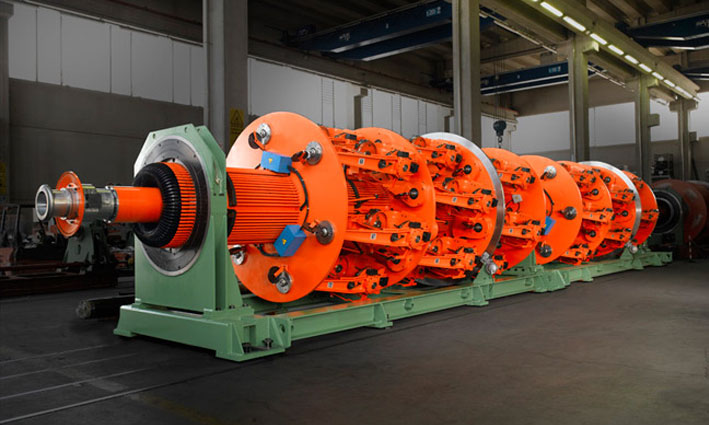

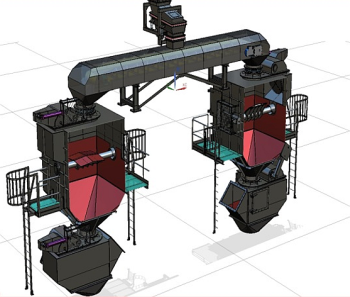

Stranding and closing planetary machines are huge pieces of equipment designed to twist multiple heavy spools of strand at noticeable speed, to manufacture large section steel ropes.

recurdyn multibody mechanics

CASE STUDY

This study was part of the Virtual Optimization PAsta production process (OPAV) research project,

modefrontier ansys ls-dyna magma optimization food-beverage consumer-goods

CASE STUDY

Sport equipment design is characterized by the fact that a fundamental part of a product success depends on the athlete’s feedback.

sports modefrontier ansys ls-dyna

CASE STUDY

In this technical article, the authors discuss the development of CAE models for simulating the behavior of shaped charges, devices used in various industrial sectors, against two types of target – a monolithic steel target and a multi-layer steel-ceramic target – in order to better understand the physics of penetration.

ansys ls-dyna civil-engineering mechanics oil-gas

CASE STUDY

In this technical article, a CFD study of various designs for four different specialty tractors: two brands of specialty tractors for vineyard configurations, and two brands of specialty tractors for orchard configurations, are described.

automotive ansys cfd

CASE STUDY

This analysis attempts to understand the behavior of sticky detergent powders according to flow velocity using Rocky-Ansys Fluent two-way coupling.

consumer-goods rocky ansys

CASE STUDY

Dynamic studies are required to predict the accelerations, verify that the cams are properly shaped, and to extract the loads to structurally size the parts.

recurdyn multibody mbd-ansys automotive

CASE STUDY

In this article, we present a procedure to investigate the thermo-mechanical effects produced by the particles of an extremely focused beam hitting a material target spot.

ansys

CASE STUDY

In this case study, LION Corporation uses Particleworks to simulate fluid flow to improve the design of a new cap spout for its new HARETA brand of laundry detergent.

particleworks cfd consumer-goods mechanics

CASE STUDY

GE Power is a world leading supplier of solutions for power generation, from engineering to manufacturing. Detecting and mitigating critical flow structures in water pumping stations is a complex engineering task, that has always been based on experimental activities. Now GE Power can rely also on CFD modelling and on the support of EnginSoft

ansys cfd energy

CASE STUDY

A lot of steel structures such as cranes, heavy machinery and other equipment subjected to repetitive loading is highly likely to develop cracks or failures because of the fatigue damage. The cost of every hour of equipment downtime is usually very expensive, making it mandatory to perform residual life calculations or fatigue checks.

ansys energy

CASE STUDY

Mesh morphing has proven to be a valuable tool in parametrizing numerical models to perform shape optimization. It allows engineers to save time in generating new configurations for analysis because it does not require geometry modification and mesh re-generation.

ansys mechanics

CASE STUDY

A multibody model of an excavator was developed to calculate the loads acting on the structure and to perform static structural verifications of the different components.

automotive multibody recurdyn mechanics

CASE STUDY

This technical article describes a project that was undertaken by TAE SUNG Software and Engineering, in collaboration with DY AUTO in Korea, to establish a computerized process to conduct three-dimensional real-scale analysis of any of the three types of windshield wiper currently in use, and to establish a specific standard for evaluating wiper performance.

automotive ls-dyna ansys

CASE STUDY

This project has been coordinated by the German Aerospace Center (DLR) and it is embedded in the MELiSSA framework of ESA research projects.

aerospace cfd ansys

CASE STUDY

Today the numerical simulation offers an important added value for dimensioning and testing of the motorbike’s chassis.

rail-transport ansys

CASE STUDY

The following article explains how this new approach to the design of automated machines can enable industrial automation OEMs and system integrators to achieve these business imperatives with the assistance of industrialPhysics simulation software.

mechanics iphysics industry4

CASE STUDY

In this technical case study, EnginSoft was called in to assist in the application of Computational Fluid Dynamics (CFD) to model the flame size of a regeneration gas-fired heater for a project in Oman.

ansys mechanics energy oil-gas

CASE STUDY

This case study describes ISEO’s project to introduce a global dimensional management approach based on CETOL6σ that starts from the product concept phase and includes design development and prototyping and extends on to cover all other phases of production through to the finished product, with the guidance and support of EnginSoft.

tolerances cetol mechanics

CASE STUDY

A new methodology is presented, following an integrated process-product analysis approach, showing some benefits related to increased accuracy and the potential application of new optimization methods.

ls-dyna automotive composites

CASE STUDY

Gamma Meccanica’s R&D department is constantly researching new solutions to improve the overall performance of equipment, production capacity and reliability while developing environmentally sustainable processes and applications to benefit its customers.

cfd mechanics ansys

CASE STUDY

This article discusses a realistic multi-objective parameter optimization study of a highly athletic one-legged robot, called Skippy, in which both the parameters of the mechanism and the parameters of its optimal behaviors were sought.

optimization modefrontier biomechanics

CASE STUDY

Performing flow simulations to investigate the complex loss mechanisms caused by the interaction of the rotating oil ring within a piston in the inside of the roll of a calender, which is an important device of a paper machine. Hereby, the trends of the churning losses are determined for design improvement conducted by Voith Paper R&D.

particleworks mechanics

CASE STUDY

Oil or gas pipelines that cover long distances pose complex design challenges. Every environment the pipeline crosses is characterized by different potential geohazards. One of the most dangerous for a pipeline is a rockfall.

oil-gas mechanics ansys

CASE STUDY

This paper presents the preliminary simulation study of a typical centrifuge currently produced by Gamma Meccanica. The objective of this study is to evaluate the behaviour of the centrifuge using moving particle simulation and discrete element method (MPS-DEM) simulation techniques with Particleworks 7.2.1 to gain a better understanding of phenomena that are impossible to monitor experimentally.

mechanics particleworks

CASE STUDY

This is a classic scenario that exploits the best features of RecurDyn software, such as the Full-Flex and the Geo-Contact technology.

recurdyn multibody mbd-ansys

CASE STUDY

The aim of this study was to reduce the weight of the world’s tallest aluminum mast for a new series of single mast sailing yachts manufactured by Perini Navi under the brand name Salute.

optimization modefrontier ansys marine rail-transport

CASE STUDY

The growth of technology and end-user expectations is ever more important in many application areas and medical devices are at the forefront of this innovation process.

ansys electronics

CASE STUDY

The residual strength, in particular the compression strength after damage due to low velocity impact, is one of the most critical issue for composite laminates.

ls-dyna aerospace modefrontier composites

CASE STUDY

The avoidance or reduction of chainsaw kickback is a key safety feature for manufacturers. The challenges for engineers are to obtain more accurate analyses of the problem over the tool’s lifecycle.

maplesim maple mechanics ansys consumer-goods

CASE STUDY

This technical paper presents an analysis process to accurately examine the environmental loads and structural stability of a Floating photovoltaic (PV) power plant. The method includes a hydrodynamic analysis of the Floating PV in its water-based environment as well as a structural analysis of its structural stability based on the characteristics of motion it undergoes.

ansys energy

CASE STUDY

By taking advantage of EnginSoft experience in Simulation Based Engineering, by means of the FEM analysis, the Durability, Structural Integrity and Buckling behavior of a new group of toxic liquid and fuel storage tanks have been investigated.

energy mechanics ansys

CASE STUDY

In this interview, engineer Luca Cavalli, of Immergas’ advanced engineering team, discusses the technical and business benefits the company has realised since first introducing Computer-Aided Engineering (CAE) technologies into its R&D department in 1997.

ansys appliances cfd mechanics

CASE STUDY

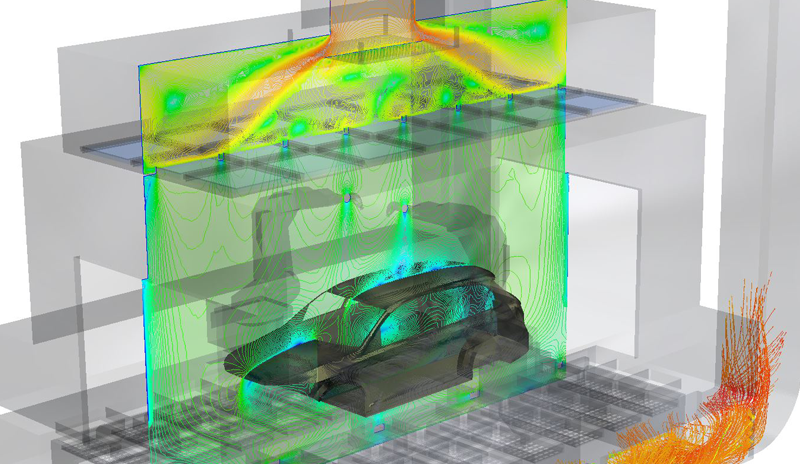

Overspray is a key problem in the paint application process. This phenomenon is caused by inefficiencies of the robots inside the spray booth and can best be solved by balancing the air flow properly in the paint application area.

automotive ansys cfd

CASE STUDY

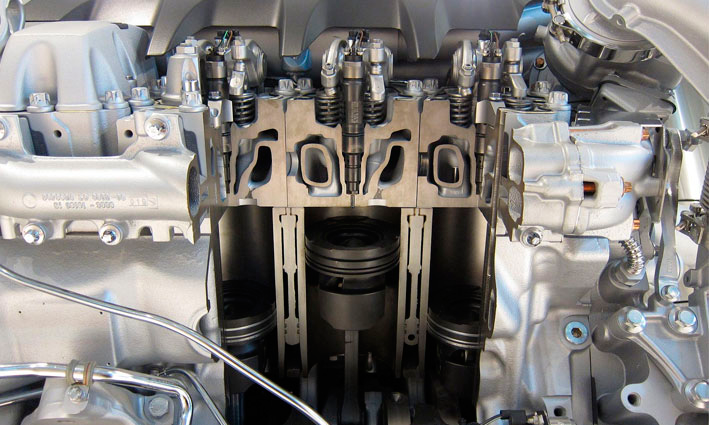

The connecting rod is one of the most important components in powertrain systems, so it requires very careful structural analyses because its failure implies serious damage to the entire engine.

automotive ansys rail-transport

CASE STUDY

In the lime industry, the process engineers of Cimprogretti advise on process safety, analyse and interpret laboratory and plant data and provide specialised support to ensure the technical integrity of equipment and plants.

mechanics rocky

CASE STUDY

Optimization tools, and specifically response surface methods (RSM), can be adapted very well in the design process to provide information around the design of a compressor stage. This article will cover two of the possible optimization uses: the search of optimum performance and data generation.

modefrontier optimization mechanics