Ansys Additive Suite

The most powerful simulation solution for metal additive manufacturing

Ansys is a software suite of Ansys Inc.

Ansys is a software suite of Ansys Inc.

Ansys Additive Suite delivers the critical insights required into the develop and analysis of an AM product to avoid build failure and create parts that accurately conform to design specifications. This comprehensive solution spans the entire AM workflow, from design for additive manufacturing (DfAM) through validation, print design, process simulation and exploration of materials.

Ansys Additive Suite is available as an add-on to the Ansys Mechanical Enterprise license. Therefore, it combines the native features and capabilities offers within Ansys Mechanical like structural, thermal, acoustic and other effects analysis, the built in Topology Optimization to find optimum geometry shapes that efficiently meet objectives and Ansys SpaceClaim Direct Modeler with its toolsets for reverse engineering faceted/scanned data, and editing or optimizing STL files for additive manufacturing and 3D printing along with specific tools related to AM. It means the access to the Ansys Workbench environment streamlining the setup and resolution of AM simulations, while offering maximum flexibility according to the required needs.

brochure

Ottime potenzialità nella riprogettazione di parti di macchine e stampi per la produzione

Ansys Additive

Send your technical questions to our experts!

Connect you with an EnginSoft expert who can provide a reliable answer to your technical question or recommend a

proven solution.

CASE STUDY

Gamma Meccanica’s R&D department is constantly researching new solutions to improve the overall performance of equipment, production capacity and reliability while developing environmentally sustainable processes and applications to benefit its customers.

cfd mechanics ansys

corso a calendario online

Corso sulle batterie al litio, organizzato in quattro moduli principali, ciascuno dei quali si concentrerà su aspetti fondamentali della tecnologia.

training oorja

CASE STUDY

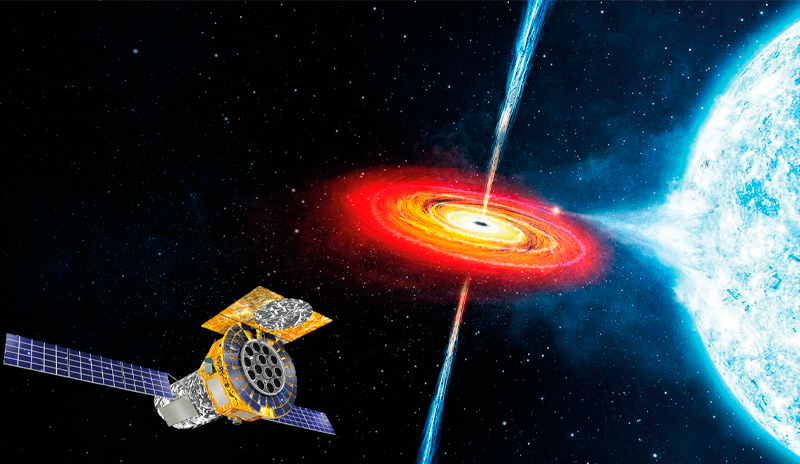

This article describes the preliminary study resulting in the design solutions adopted for the LAD module’s most important thermo-mechanical drivers, which were developed and used to demonstrate compliance with the system requirements at the spacecraft level.

aerospace rbf-morph ansys

CASE STUDY

This article presents a study that the Elica Group commissioned from EnginSoft to support it engineering team in redesigning the ventilation system of its “Tilly” kitchen hood model

appliances ansys cfd

CASE STUDY

This study discusses the complex and challenging problem of controlling vortex-induced vibrations (VIV).

cfd mechanics ansys rbf-morph