Aeronautic

The SMEA project studied and implemented diagnostic and prognostic methodologies, supported by appropriate sensors, to monitor the functional integrity of mechanical components typical of the aviation and transport sectors. The adoption of Prognostics Health Monitoring (PHM) systems in the aviation sector, and more generally in transport, aims to achieve the triple objective of increasing flight safety, increasing system availability, and reducing the cost over the life cycle of the component. This challenge requires the implementation of monitoring systems linked to the digital model with the ability to identify incipient faults in mechanical systems. This approach is highly innovative and competitive in the market and more attractive to the customer with improvements in safety, reduced downtime and operating costs.

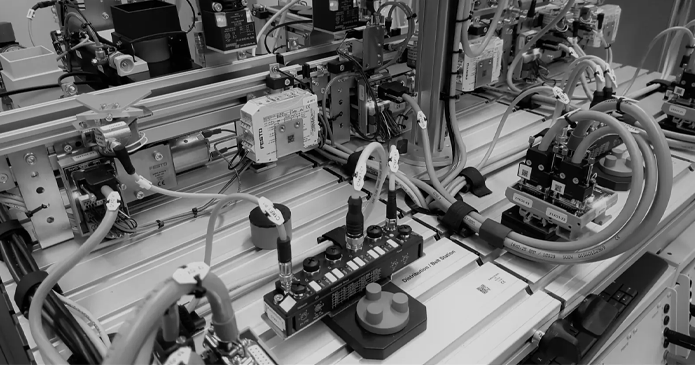

The developed solution requires the integration of multi-disciplinary tools and methods to address the design and production development of a structural component (the demonstrator) made with advanced materials and innovative production processes (e.g. Additive Manufacturing). The PHM system includes multi-scale models, data acquisition and non-destructive investigation systems, in order to predict and verify the real performance capacity of the component in service. The validation of the Digital Twin, applied to the component produced using L-PBF, required the development of a graphical interface for Calibration and Signal Analysis, Historical Correlation Analysisi and Component Diagnostics in service or under test conditions.

Through an innovative Digital Twin approach in Prognostics Health Monitoring (PHM), it is possible to identify abnormal behavior of the monitored systems that could lead to unexpected failures during service by increasing the fault diagnostic capacity. Monitoring allows for better planning of the maintenance program by being able to assess intervention costs and the residual efficiency of the system.

EnginSoft's role was to develop the Digital Twin which integrates failure indicators with control and monitoring parameters in order to calibrate numerical simulation models and the resulting Reduced Order Modeling (ROM). A first phase involved the development of the new hinge design in aeronautical aluminum alloy (Design for Additive Manufacturing - DfAM) with the Ansys Additive Suite. Calibration of the model involved structural validation as a whole and in the point values measured by the selected sensors (strain gauges). ROM models were developed to map the stress and strain distribution from the point data of the actual sensor signals. Finally, EnginSoft developed the entire Digital Twin with the connectivity of the strain gauges and their location on the geometric model, the real-time visualization of the 3D stress map, and the processing of the health status of the component in terms of fatigue.

DTA SCARL - Distretto Tecnologico Aerospaziale Pugliese, Università del Salento, ENGINSOFT SpA, Avio Aero, CNR, Leonardo Spa - Divisione Velivoli (osservatore)

Avviso n. 713/Ric. del 29/10/2010

Titolo III – “Creazione di nuovi Distretti e/o Aggregazioni Pubblico Private”

12 months

October 2019 – March 2023

DTA SCARL - Distretto Tecnologico Aerospaziale Pugliese

Vito Primavera

6

Some of our competences in research and technology transfer

Research project

Development of a novel “manufacturing system-level quality and productivity optimizer tool” enabling the evaluation of the system level impacts of the defect avoidance policies that can be adopted within single processes.

Research project

Metal Additive manufacturing is a complex operation that requires the fine-tuning of hundreds of processes parameters to obtain repeatability and a high quality design at dimensional, geometric, and structural levels. To help manufacturing companies address these challenges, AMQ_TOOLS develops an innovative quality-oriented decision support framework.