MUSIC

MUlti-layers control&cognitive System to drive metal and plastic production line for Injected Components

Manufacturing/ICT

Control and Cognitive system to drive Injected Components production lines

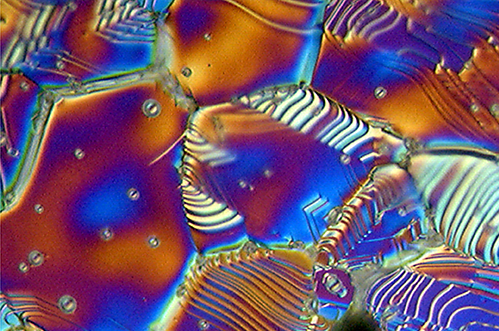

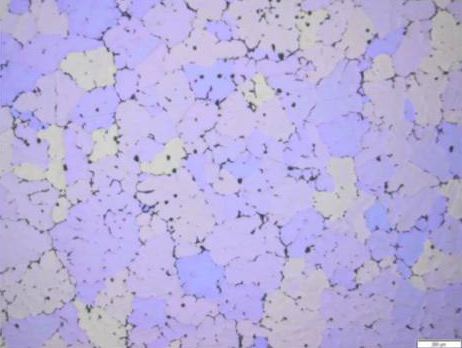

Due to the high number of process variables involved and to the non-synchronisation of the process control units, High Pressure Die Casting (HPDC) of light alloys and Plastic Injection Moulding (PIM) are most “defect-generating” and “energy-consumption” processes in EU industry showing less flexibility to any changes in products and in process evolution. Therefore, the MUSIC is strongly aimed at leading EU-HPDC/PIM factories to cost-based competitive advantage through the necessary transition to a demand-driven industry with lower waste generation, efficiency, robustness and minimum energy consumption. The development and integration of a completely new ICT platform, based on innovative Control and Cognitive system linked to real time monitoring, allows an active control of quality, avoiding the presence of defects or over-cost by directly acting on the process-machine variables optimisation or equipment boundary conditions.

The challenge of MUSIC is to transform a production-rate-dominated manufacturing field into a quality/efficiency-driven and integration-oriented one to exploit the enormous (and still underestimated) potential of HPDC/PIM through collaborative research and technological development, along the value chain through advances in manufacturing, ICT and model process technologies.

Exploitation of data acquisition, data elaboration and process modeling capabilities for the implementation of a commercial software for future distribution within manufacturing sectors.

EnginSoft SpA | Electronics GmbH | University of Aalen – GTA | MAGMA GmbH | University of Padova – DTG | Fundacion Tekniker | Eurecat - Technology Centre of Catalonia | Oskar Frech GmbH + Co. KG | Saen | Maier S.Coop | Audi AG | RDS Moulding Technology | Motul | Regloplas AG | Fraunhofer-Institute IFAM | Assomet Servizi

Funding Scheme FP7 Collaborative Project | Call identifier FP7-2012-NMP-FoF-ICT

48 months

September 2012 - August 2016

EnginSoft Spa

Nicola Gramegna

16

Some of our competences in research and technology transfer

Research project

The GAP Project’s innovativeness lies in the development of innovative metallic materials with multi-sector application potential, increased by experimentation with new specific technologies (e.g. the use of ceramic cores for die-casting, surface treatments, and joining techniques).

Research project

Il progetto “TEMART - Tecnologie e materiali per la manifattura artistica, i Beni Culturali, l’arredo, il decoro architettonico e urbano e il design del futuro” ha l’obiettivo di migliorare i prodotti dei settori citati (funzionalità ed estetica) mettendo a loro disposizione le diverse tecnologie che sono presenti nella RIR M3NET.

Research project

The SMEA project studied and implemented diagnostic and prognostic methodologies, supported by appropriate sensors, to monitor the functional integrity of mechanical components typical of the aviation and transport sectors.