Smart Materials

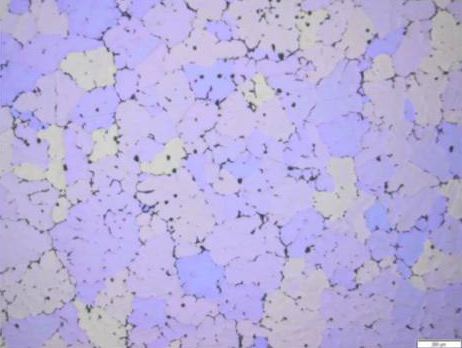

In the various fields of industrial production, increasing attention is being paid to the design and manufacture of high-performance components using highly innovative materials, such as cast iron (austempered, high-silicon, compact graphite) and light alloys (aluminum-silicon or aluminum-magnesium alloys, with added elements to optimize their microstructure). These materials belong to the area of "lightweight design": their mechanical properties, possibly combined with low density values, enable the creation of lightweight components of reduced thickness, at low environmental impact providing significant advantages in the transport, consumer goods, and mechanics sectors.

- There are still several factors, however, hindering the full realization of the application potential of these materials. The GAP Project aims to analyze and overcome them, by:

The target markets for the innovative alloys being developed within the GAP project are:

The GAP Project’s innovativeness lies in the development of innovative metallic materials with multi-sector application potential, increased by experimentation with new specific technologies (e.g. the use of ceramic cores for die-casting, surface treatments, and joining techniques).

EnginSoft’s manufacturing operations units (Foundry and Metal Forming) and its mechanical designers are involved in the development and implementation of the materials database, as well as the development of design case histories. The company’s goal is to produce reliable databases and design methodologies that take into account the effect of microstructures and defects on the performance of both the novel (and conventional) alloys.

Partners: CONSORZIO SPRING – STRATEGIC PARTNERSHIP FOR RESEARCHED-BASED, INNOVATIVE AND NETWORKED GROWTH, ECOR INTERNATIONAL SPA, ENGINSOFT SPA, FONDERIA CORRA' SPA, ITALKER SRL, LINO MANFROTTO + CO SPA, RDS MOULDING TECHNOLOGY SPA, SLIM FUSINA ROLLING SRL, UNILAB LABORATORI INDUSTRIALI SRL, UNIVERSITA' DI PADOVA – DTG, ZANARDI FONDERIE SPA

Funding Scheme POR - Obiettivo "Incremento dell'attività di innovazione delle imprese" - Parte FESR fondo europeo di sviluppo regionale 2014 - 2020

ERDF EUROPEAN DEVELOPMENT FUND 2014 - 2020

“Progetto finanziato con il POR FESR 2014-2020 Regione del Veneto” - ASSE 1 “RICERCA, SVILUPPO TECNOLOGICO E INNOVAZIONE” AZIONE 1.1.4 “Sostegno alle attività collaborative di R&S per lo sviluppo di nuove tecnologie sostenibili, di nuovi prodotti e servizi”

"Project co-funded by POR ERDF 2014-2020 Regione del Veneto" - AXIS 1 "RESEARCH, TECHNOLOGICAL DEVELOPMENT AND INNOVATION" ACTION 1.1.4 "Support for collaborative R&D activities for the development of new sustainable technologies, new products and services"

Importo finanziamento: € 1.471.548,86 / Grant Amount: € 1.471.548,86

24 months

November 2017 - October 2019

CONSORZIO SPRING

Nicola Gramegna

12

Some of our competences in research and technology transfer

Research project

LUBFORLIFE’s ultimate goal is the integration of innovative components and technologies into electromechanical actuators, for aircraft and UAV flight controls, which do not require relubrication during their entire operating lifes.

Research project

Il progetto supporta alcune aziende della rete SINFONET nell'utilizzo di servizi specialistici, di assistenza, orientamento, affiancamento, informazione e promozione dell’export, per promuovere non solo le proprie specificità ma anche l’intero complesso della filiera fonderia.

Research project

L’attività svolta, nell’ambito del progetto CUP B98I24002620009, si contraddistingue per due servizi volti a migliorare competenze, metodi e strumenti applicati al Process Engineering e Sistemi Informativi per il Knowledge Management (KM) e GoToMarket (GTM).