ForZDM

Integrated Zero Defect Manufacturing Solution for High Value Adding Multi-stage Manufacturing systems

Smart manufacturing

The ForZDM project developed and demonstrated tools to support the rapid implementation of Zero-Defect Manufacturing solutions in industry, and to design more competitive and robust multi-stage manufacturing systems.

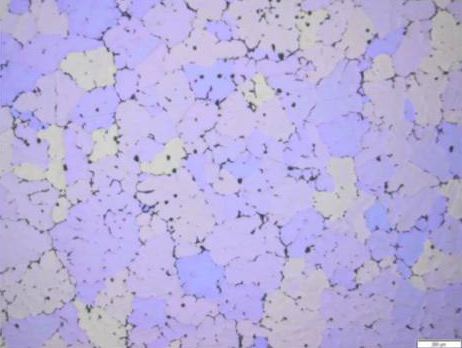

Manufacturing companies face the challenge of delivering high quality products of increasing complexity, with limited use and waste of resources. "Zero Defect Manufacturing” (ZDM) is a recent paradigm aiming at going beyond traditional six-sigma approaches. The aim of the ForZDM project was to develop and demonstrate tools to support the rapid deployment of ZDM solutions in the industry and to design more competitive and robust multi-stage manufacturing systems. The ForZDM methodology expands current single process boundaries towards a production line perspective, which allows to contrast defects before, during and after their generation through diagnosis, preventive and corrective mechanisms, applied with real-time, medium term and long term control actions.

The proposed ZDM approach is based on the combined adoption of new solutions based on data collection and root cause analysis to reduce defect generation as well as new in-line defect management and improved production traceability solutions to mitigate defect propagation along the production line stages. This was achieved through the proper integration of innovative enabling technologies, such as cyber-physical systems, selective inspections, advanced analysis and integrated process, system-level modelling and simulation and partial flow control solutions.

EnginSoft supported the development of the ZDM System Level Engineering and Control platform, a Decision-Support System tool able to identify optimal assignment, routing, scheduling and planning policies for manufacturing. It expanded the range of modeFRONTIER applications and created a new product in a market where no competing software package exists. modeFRONTIER is an integration platform for multi-objective and multi-disciplinary optimization.

GKN AEROSPACE NORWAY AS, ABF-INDUSTRIELLE AUTOMATION GMBH, CAF, ENGINSOFT SPA, ENKI SRL, IK4-IDEKO, MARPOSS SPA, MASMC SPA, MONTRONIX, NXTCONTROL GMBH, POLITECNICO DI MILANO, TECNALIA RESEARCH & INNOVATION, UNIVERSITY OF STUTTGART

Funding Scheme Horizon2020 | Call identifier H2020-FOF-03-2016

48 + 6 months

October 2016 - March 2021

GKN AEROSPACE NORWAY AS (until August 2020) | Politecnico di Milano (since September 2020)

Giovanni Borzi

12

Some of our competences in research and technology transfer

Research project

The project aims to combine performance optimization of company with a strong investment in human capital, creating a highly digitalized business environment to make the company more competitive, efficient and ready to face future challenges: this will be achieved thanks to a more competent and prepared team, through the introduction and use of innovative applications and systems, aimed at simplifying daily processes and operations.

Research project

The GAP Project’s innovativeness lies in the development of innovative metallic materials with multi-sector application potential, increased by experimentation with new specific technologies (e.g. the use of ceramic cores for die-casting, surface treatments, and joining techniques).

Research project

Development of methodologies (and of laboratory version of a software platform designed to implement them), capable of supporting architects and engineers in designing eco-buildings characterized by an optimal compromise between environmental performance (in terms, for example, of the CO2 equivalent produced during their entire life-cycle) and costs