ExaNeSt

European Exascale System Interconnect and Storage

HPC (High Performance Computing)

ExaNeSt studies architectural solutions to store and share data in a unified manner.

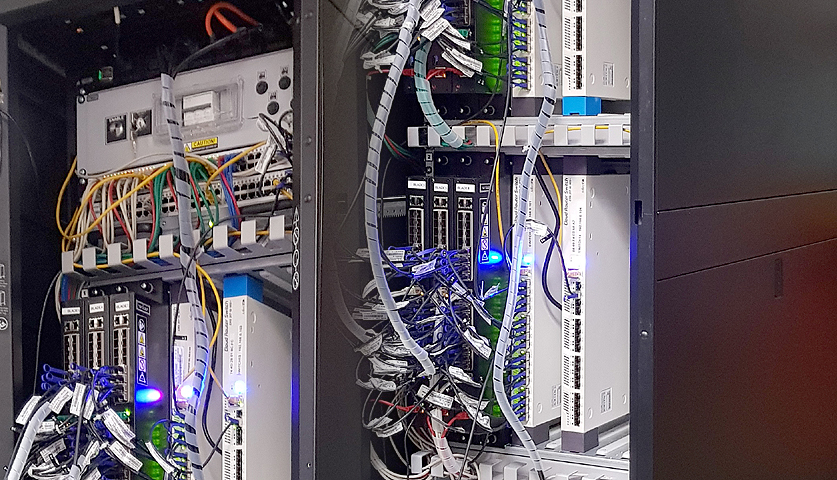

A prototype of a physical platform and rack systems, needed to realize European exascale systems, are developed.

A solution to support industrial marketing and follow-up of exascale systems is developed following recommendations of the ETP4HPC roadmap.

The consortium collects technology and experience on the whole HPC process: applications, algorithms, operating systems, data-storage, HPC communication, packaging and system configuration, kernel tuning, data management and analysis of applications.

An innovative high efficiency Exascale level calculator is modeled, simulated and validated through prototype.

The new system has the following peculiarities: high productivity, unified storage and distributed computing, low power consumption and complexity, limited maintenance and database management costs quality of Service guarantees and resilience, storage and distributed localization of computing elements anagement of I/O in order to alleviate congestion, low latency connectivity, which is foundamental for non-volatile memory, support for task-to-data sw; models, integration scheme for the Hyper-Density system: a commercial European modular cooling system for Exascale applications in ~ 200 rack that guarantees reliability and reduced operating costs.

EnginSoft testes the ExaNest platform with various CAE applications which often require parallelism and big data management.

These applications are both commercial and Open Source and are dedicated to the most relevant computational science areas like mechanics, fluid-dynamics, fast dynamics and crash, metallurgy, process simulation, porous media, environmental engineering, off-shore engineering, acoustic analysis, process integration and design optimization (PIDO).

EnginSoft also assists the Foundation for Research and Technology Hellas in coordinating and administrating the project.

Allinea Software Ltd | EnginSoft Spa | eXact Lab Srl | Fraunhofer Institut | FOundation for Research and Technology Hellas (FORTH) | Iceotope | ISTITUTO NAZIONALE DI ASTROFISICA (INAF) | Istituto Nazionale di Fisica Nucleare (INFN) | Monet DB | Universitat Politecnica de Valencia | University of Manchester | Virtual Open Systems

Funding Scheme Horizon2020 | Call identifier H2020-FETHPC-2014

42 months

December 2015 - May 2019

FOundation for Research and Technology Hellas (FORTH)

Gino Perna

12

Some of our competences in research and technology transfer

Research project

Attraverso un innovativo approccio Digital Twin in ambito Prognostics Health Monitoring (PHM) è possibile l’individuazione di comportamenti anomali dei sistemi monitorati, che potrebbero portare a rotture impreviste durante il servizio, aumentando la capacità di diagnostica di guasto. Il monitoraggio consente una migliore pianificazione degli interventi manutentivi potendo valutare costi dell’intervento ed efficienza residua del sistema.

Research project

The main aim of the project is to set out the knowledge and skills that a competent simulation engineer (CAE engineer) should possess, and to develop a set of tools that will enable engineers to develop, manage and certify their competencies within a wide range of industry sectors.

Research project

SERENA intende sviluppare un sistema propulsivo prototipale per un velivolo di categoria di Aviazione Generale basato su tecnologie di alimentazione ibride (celle a combustibile alimentate a idrogeno, batterie e super-capacitori).