Manufacturing

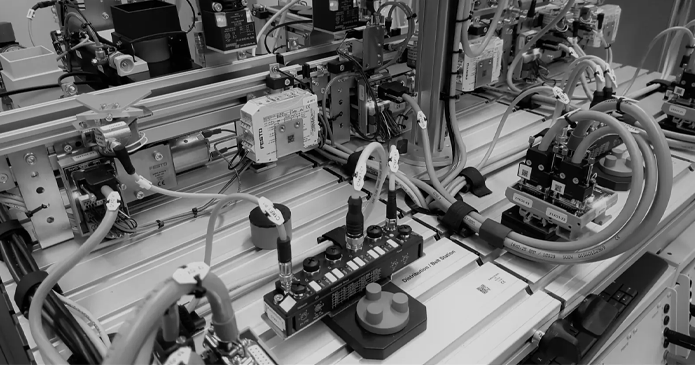

The AMQ_TOOLS project’s results include validated quality-oriented predictive models that support the selection of optimal combinations of process parameters in advance and the in-process verification of quality results. The models, which are integrated into the CPS, enable improvements in critical manufacturing KPIs such as lead time (e.g. reducing the need for downstream quality inspections and reducing production time) and component quality (e.g. reducing porosity). AMQ_TOOLS addresses Additive Manufacturing (AM) quality control with a decision support framework which integrates a Design for AM (DfAM) and a process simulation software solution (ANSYS Additive Suite), with the Smart ProdACTIVE digital platform that connects the AM machines (EOS M290) with quality assurance requirements and quality control data. Smart ProdACTIVE is a fully integrated system, that links production processes with data sources (machines, sensors, HMIs), and uses traceability information to correlate this data with quality results. Therefore, ProdACTIVE will enable the smart monitoring of Additive Manufacturing processes through the application of quality-oriented predictive models and machine learning algorithms, which can be applied in real time. These models predict the presence of defects, by category, area and grade.

Metal Additive manufacturing is a complex operation that requires the fine-tuning of hundreds of processes parameters to obtain repeatability and a high quality design at dimensional, geometric, and structural levels. To help manufacturing companies address these challenges, AMQ_TOOLS develops an innovative quality-oriented decision support framework, composed of (i) a Model Based Design (MBD) tool with Design for Additive Manufacturing (DfAM) features, and (ii) a Cyber-Physical System (CPS) created from the integration of an Additive Manufacturing (AM) asset with a real-time smart monitoring software application. This framework caters to the needs of process engineers and quality managers to improve a set of quality and economic KPIs.

The AMQ_TOOLS project develops, integrates and demonstrates a quality-oriented decision support framework, that includes an in-process smart monitoring system that predicts the quality KPIs of metal Additive Manufacturing. The potential impact on manufacturing KPIs is manifold: reduced AM process lead time, reduced Cost of Quality, and Energy savings.

EnginSoft's role concerns the development and operational phases of the AM QTOOLS project, specifically:

EnginSoft SpA | PARCO SCIENTIFICO TECNOLOGICO KILOMETRO ROSSO SPA | PRES-X srl

Sub-grant agreement of Digital innovation HUBs and CollAborative Platform for cyber-physical systems (HUBCAP)

Call identifier

DT-ICT-01-2019, HUBCAP Open Call #3: HUBCAP-OC3-2021/1556275, sub-grant agreement 872698

12 months

October 2021 – October 2022

EnginSoft

Giovanni Borzi

3

by Nicola Gramegna, Giovanni Paolo Borzi | EnginSoft

Domenico Stocchi, Silvia Tiberi Vipraio, Alberto Chiarello | Gruppo Ecor International

Futurities - Spring 2025

The article explores how digital transformation and Industry 4.0/5.0 technologies are revolutionizing manufacturing by integrating data-driven digital twins (ddDT) and digital shadows (ddDS) into thermal processes like brazing, welding, and additive manufacturing. These technologies enable real-time monitoring, traceability, and decision-making, significantly improving quality control, efficiency, and training.

Key concepts:

Case Studies:

The integration of digital technologies into manufacturing supports a shift toward smart, sustainable, and human-centric production under Industry 5.0. The combination of simulation, real-time data, and machine learning enhances quality control, reduces waste, and improves operator training, creating a more agile and intelligent production ecosystem.

Read the article

Some of our competences in research and technology transfer